Pulp recycling apparatus for preparing backing paper of glass substrate into pulp

A technology of regeneration device and glass substrate, used in papermaking, paper machine, wet end of paper machine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

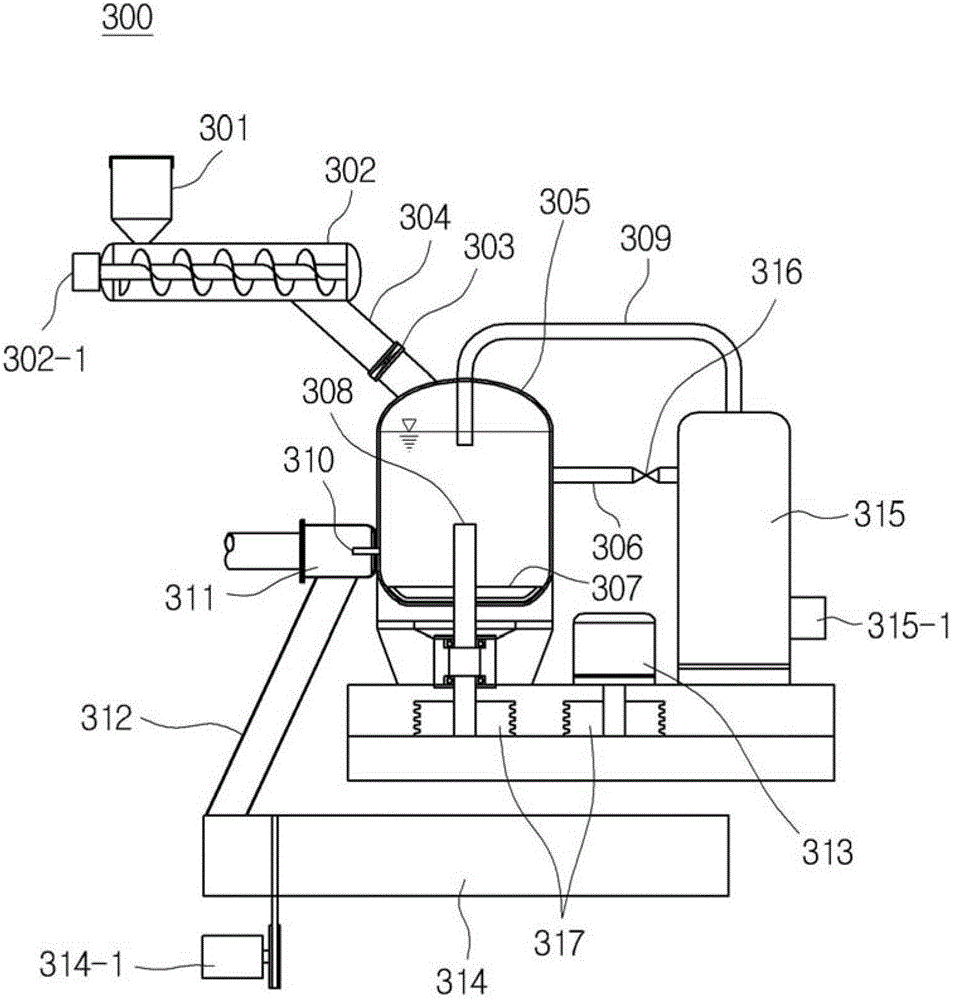

[0013] Hereinafter, a pulp recycling apparatus for making pulp from a liner paper for separating stacked glass substrates according to a preferred embodiment of the present invention will be described in detail with reference to the accompanying drawings. In the description of the present invention, it can be determined that the detailed description or construction of the prior art would unnecessarily obscure the gist of the present invention, so the detailed description thereof is omitted. In the following description, terms discussed below will be limited in the present invention in consideration of functions, and they may be changed according to the intention or practice of customers, operators or users. Therefore, definitions of terms should be construed based on the entire contents of the present invention.

[0014] Throughout the drawings, the same reference numerals are used to designate the same or similar parts.

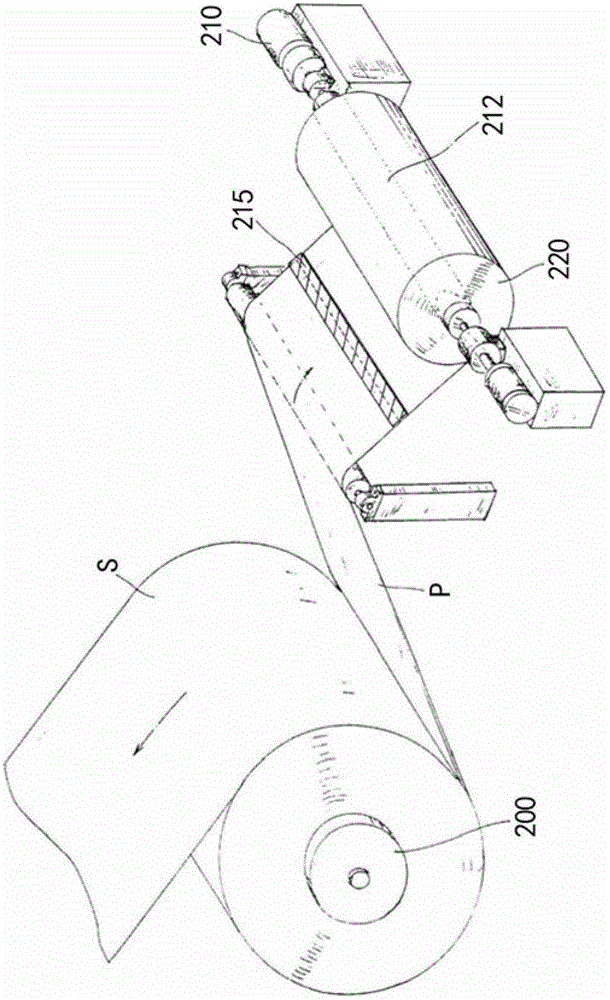

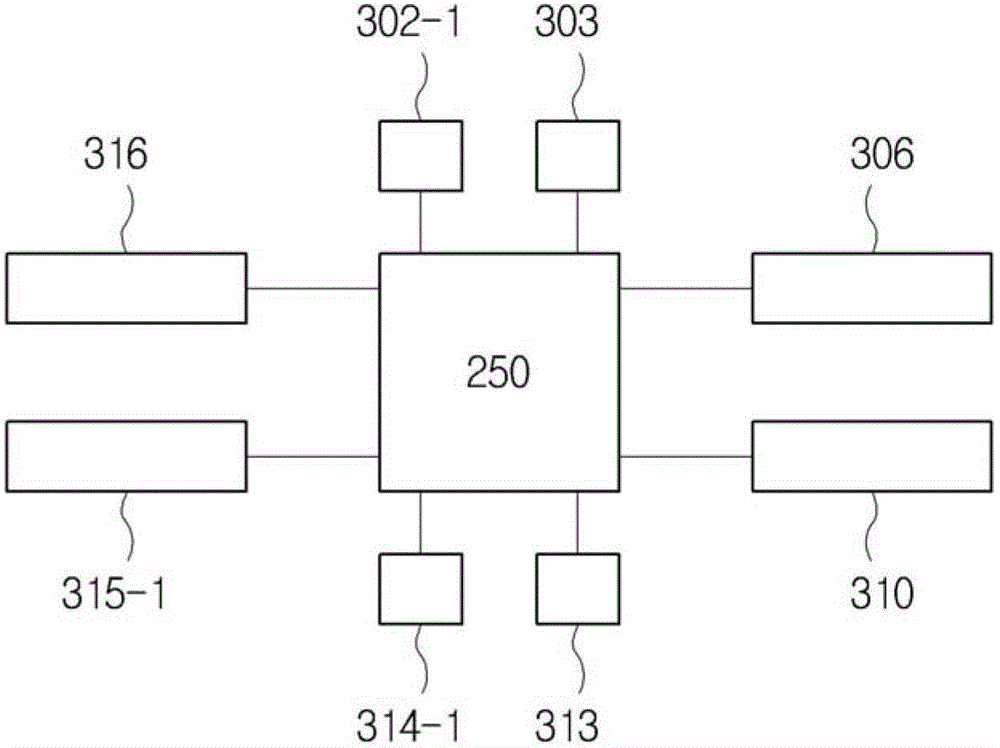

[0015] figure 2 is a schematic block diagram illust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com