Artificial composite foundation of concrete face rockfill dam built on deep and thick coverage layer and construction method of artificial composite foundation

A technology of deep covering layer and face rockfill dam, which is applied in the field of face rockfill dam construction in water conservancy and hydropower engineering, can solve the problem of uncoordinated deformation of face slab and dam body, poor stress and deformation properties of seepage prevention wall, seepage damage of dam body and dam foundation and other problems, to achieve the effect of saving the construction period of the project, eliminating the large amount of excavation works, and improving the coordination of deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, they are only examples, and the advantages of the present invention will become clearer and easier to understand.

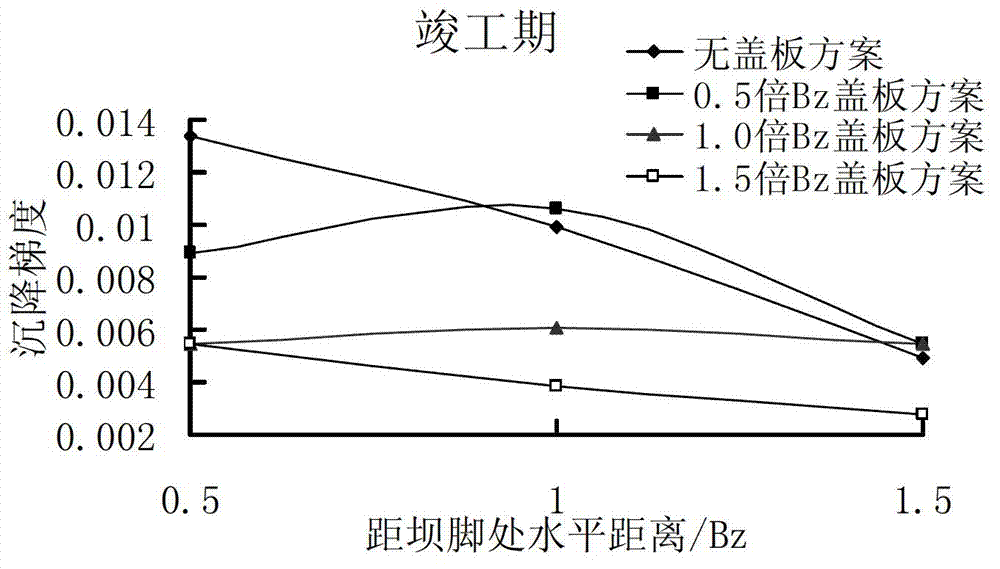

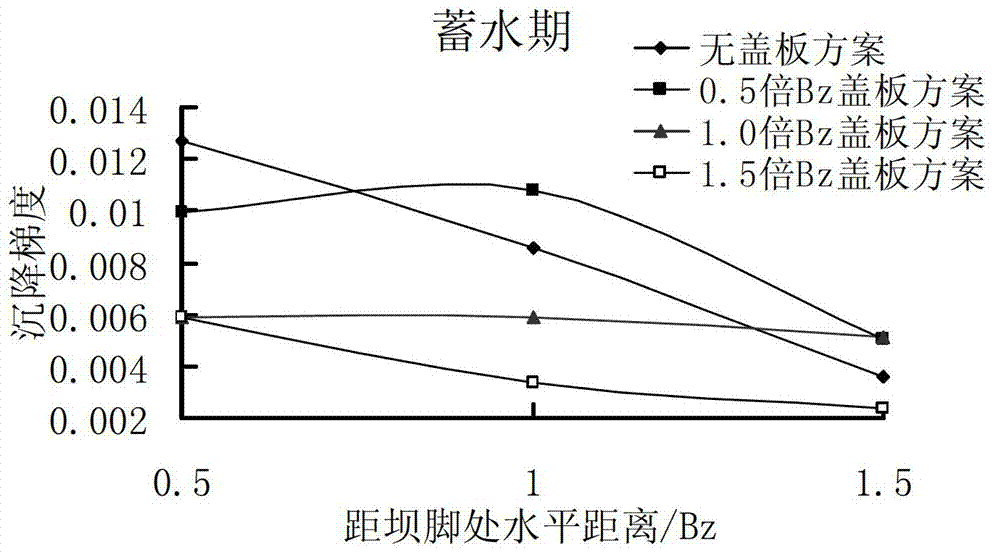

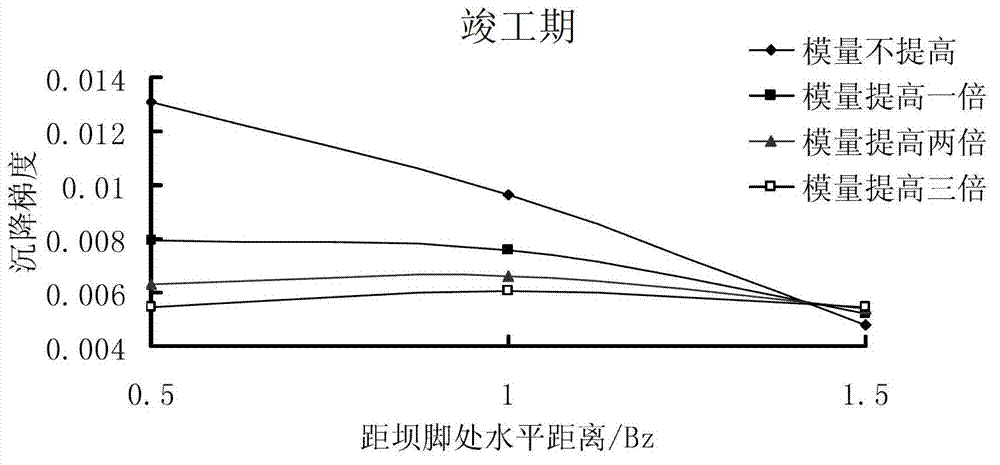

[0040] Such as Picture 1-1 , Figure 1-2 Shown: In the analysis and calculation, it is assumed that the modulus of the covering layer of the artificial composite foundation scheme is increased by 3 times, and the width of the cover plate is considered to be no cover plate, 0.5 times, 1 time and 1.5 times Bz (horizontal distance from the dam foot to the dam axis) In different cases, the calculation results are represented by the settlement gradient (the average value of the settlement gradient of every two nodes at the same elevation as the dam foot and the downstream edge of the cover plate in the finite element grid), and the larger the settlement gradient is, the la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com