Improved withdrawing technology for hydraulic supports on fully mechanized coal face

A fully-mechanized mining face and hydraulic support technology, which is applied to pillars/supports, mining equipment, earthwork drilling and mining, etc., to achieve the effects of reducing the number of workers, many parallel working locations, and a small scope of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Support models used in a working face: 115 ZZ8800-14 / 26D hydraulic supports, 6 ZZG8800-16 / 30D end hydraulic supports,

[0030] 1. Recycling method of working face hydraulic support equipment:

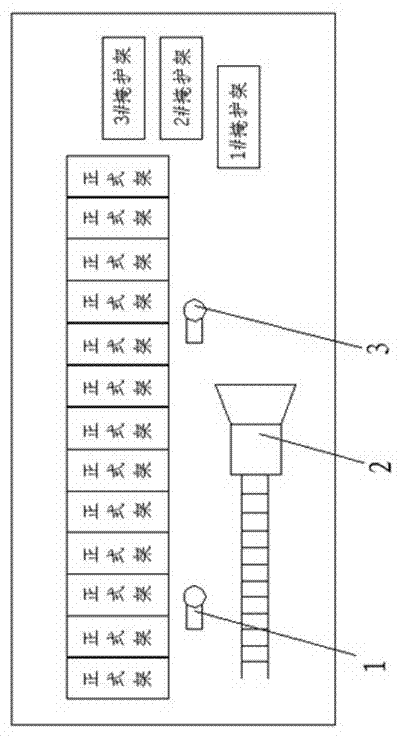

[0031] 1. After the coal mining machine, the working slide and the electromechanical equipment in Lane 1523071 have been recovered, the removal operation will be carried out. First, install two slow-speed column-returning winches 1 and 3 and a mounting platform 2 in the unloading channel of the working face. The installation position of the first column-returning winch 1 is about 20-30 brackets away from the tail of the working face for unloading Use (hereinafter referred to as the withdrawal winch); 40 brackets are installed with a movable mounting platform 2 for loading flatbed trucks on hydraulic supports; the second column return winch 3 is installed at 50 brackets for bracket loading used when.

[0032] 2. The method of removing the frame at the working face is to use 3 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com