Flexible eddy current testing probe for heat transfer pipe of steam generator of nuclear power plant

An eddy current detection probe and steam generator technology, applied in the field of flexible probes, can solve the problems of reducing detection sensitivity, increasing the radiation dose of detection personnel, reducing the filling factor, etc., to ensure detection sensitivity, increase flexibility and passability, and detect The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

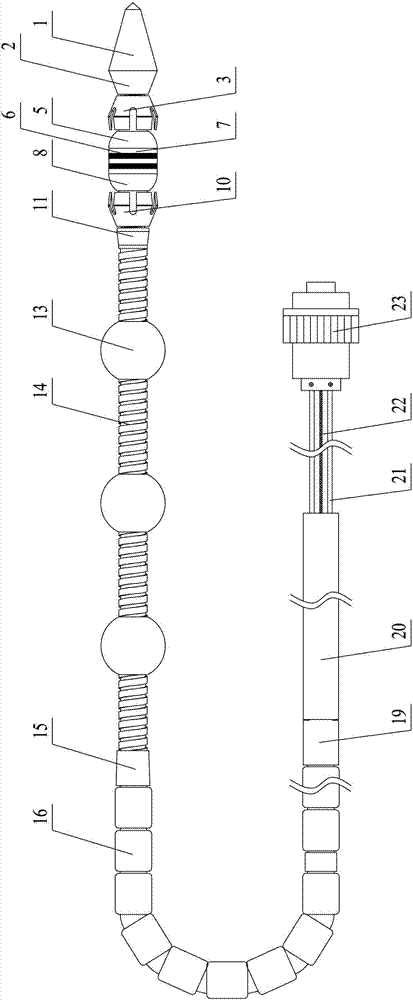

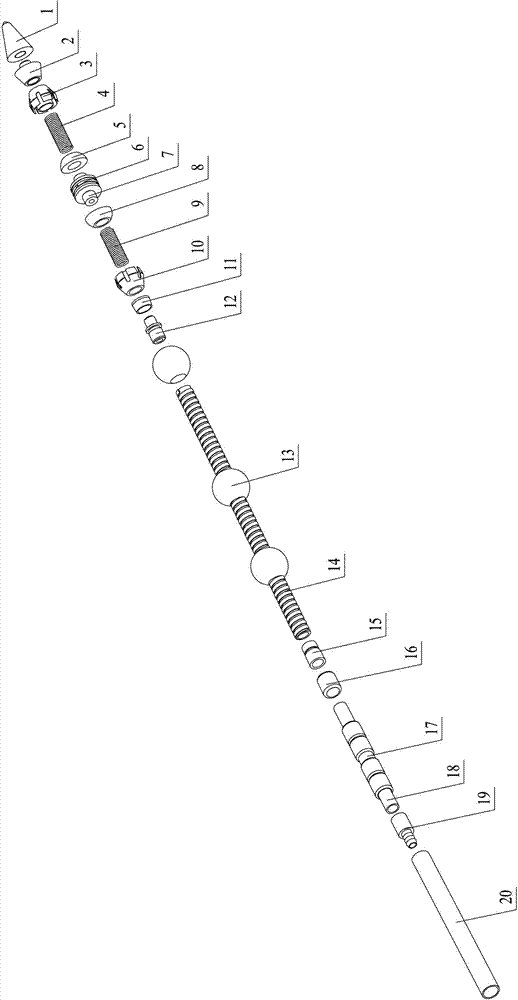

[0026] A flexible eddy current testing probe for a heat transfer tube of a steam generator of a nuclear power plant is used for eddy current testing of a heat transfer tube in a steam generator used in a nuclear power plant.

[0027] The flexible eddy current detection probe includes a guide cone, a first petal 3, a first wire slot cover 5, a skeleton 7, a coil 6, a second wire slot cover 8, a second petal 10, a collar 11, a first connector 12, and a bellows 14. A plurality of centering rings 13 , copper caps 15 , small diameter nylon tubes 18 , second connecting pieces 19 , and large diameter nylon tubes 20 are sleeved on the corrugated tube 14 .

[0028] The guide cone includes a front end 1 of the guide cone and a rear end 2 of the guide cone that are fixedly connected, and the two are connected by a thread and an adhesive structure. The rear end 2 of the guide cone, the first petal 3 and the first wire slot cover 5 are connected in series through the first spring 4 in sequ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com