Exhaust gas purification system in plateau

An exhaust gas purification system, high-altitude technology, applied in the direction of exhaust treatment, electrical control, exhaust device, etc., can solve the problems of torque drop, torque rise, damage to drivability, etc., and achieve the effect of maintaining drivability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

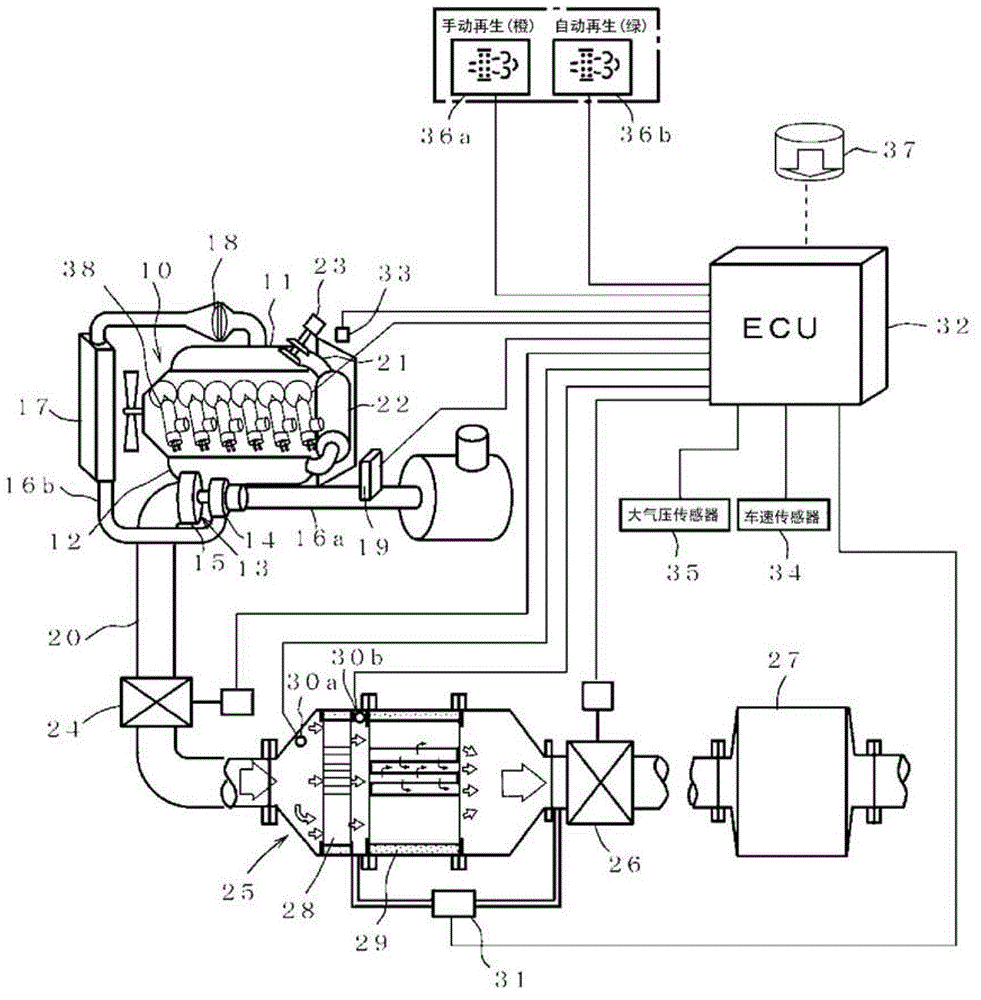

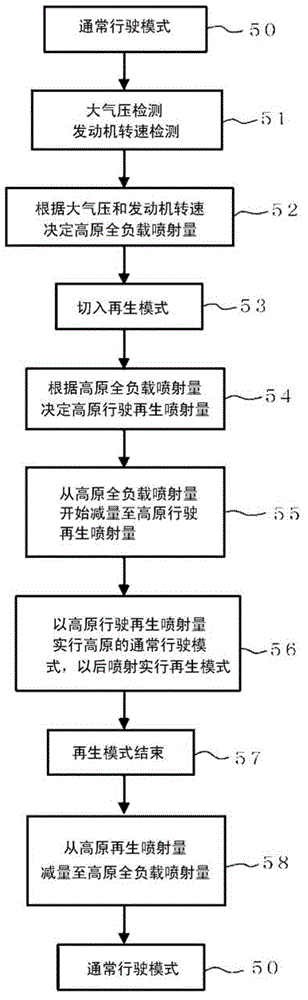

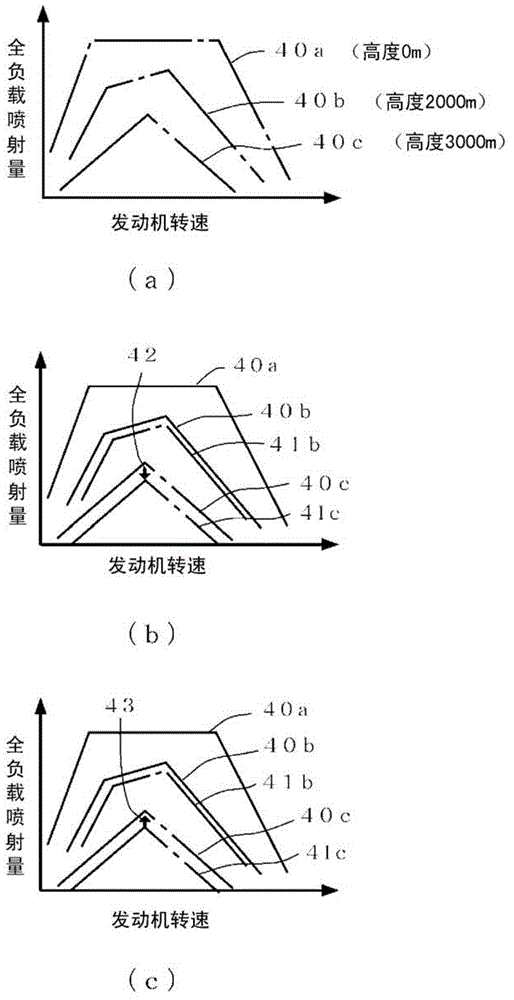

[0029] Hereinafter, a preferred embodiment of the present invention will be described in detail based on the drawings.

[0030] exist figure 1 In this process, the intake manifold 11 and exhaust manifold 12 of the diesel engine 10 are respectively connected to the compressor 14 and the turbine 15 of the supercharger 13, and the air from the upstream side intake pipe 16a is boosted by the compressor 14 and passes through the downstream The intercooler 17 of the side intake pipe 16b is cooled, and is supplied from the intake manifold 11 to the diesel engine 10 via the intake throttle valve 18, and the exhaust gas from the diesel engine 10 drives the turbine 15, and then exhausts it to Exhaust pipe 20.

[0031] An air flow sensor (MAF) 19 for measuring an intake air amount is provided in the upstream intake pipe 16 a , and the air flow sensor (MAF) controls the opening of the intake throttle valve 18 to adjust the intake air amount. In addition, the exhaust pipe 20 and the upst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com