Method for manufacturing semiconductor device

A manufacturing method, semiconductor technology, applied in the direction of semiconductor devices, single semiconductor device testing, semiconductor/solid-state device components, etc., can solve the problem of lower pass rate of withstand voltage and achieve the effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

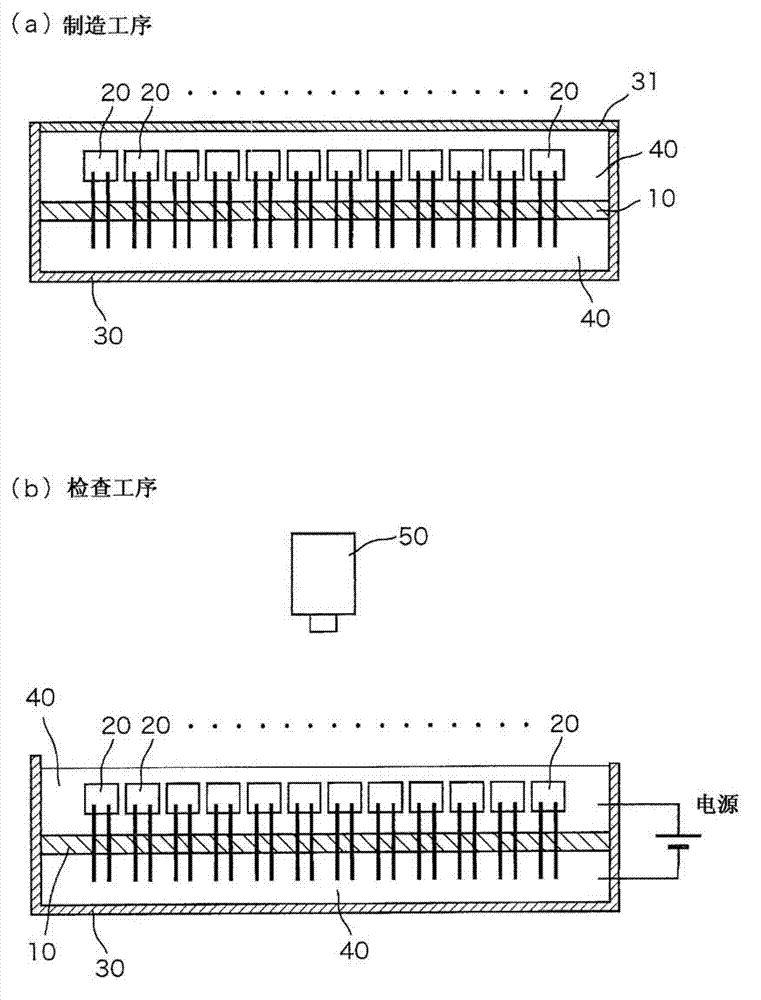

[0036] figure 1 It is an explanatory drawing explaining the outline of the manufacturing method of the semiconductor device of 1st Embodiment. The manufacturing method of the semiconductor device of the present embodiment includes: a mounting step ( figure 1 (a)), forming a circuit in which a plurality of SiC semiconductor chips 20 are connected in parallel on the mounting substrate 10; and the inspection process ( figure 1 (b)), it is checked whether the mounted SiC semiconductor chip 20 is defective.

[0037] The SiC semiconductor chip 20 is a small-capacity chip having a current capacity of about 1 to 10 A. By connecting a plurality of SiC semiconductor chips 20 in parallel on the mounting substrate 10 , a semiconductor device (for example, a power device) capable of increasing current is realized. The SiC semiconductor chips 20 have a size of about 2 mm square, and are arranged on the mounting substrate 10 at intervals of several millimeters in a straight line or in a m...

no. 2 Embodiment approach

[0060] In the first embodiment, a method of identifying a defective chip using a thermal imaging device 50 such as an infrared camera or an infrared microscope has been described, but as a mechanism for detecting heat generation in a defective chip, it is possible to use a method that changes color according to heat generation. Temperature-indicating materials such as temperature-indicating paper or temperature-indicating paint that have changed. In this embodiment, a method for identifying unqualified chips using temperature-indicating materials such as temperature-indicating paper or temperature-indicating paint is described.

[0061] In the second embodiment, the presence or absence of heat generation in each SiC semiconductor chip 20 is detected using a temperature indicating material such as temperature indicating paper or temperature indicating paint. Figure 6 It is an explanatory drawing explaining the outline of the manufacturing method of the semiconductor device of ...

no. 3 Embodiment approach

[0066] As a mechanism for detecting heat generation in defective chips, in addition to thermal imaging devices 50 such as infrared cameras and infrared microscopes, and temperature-indicating materials 60 such as temperature-indicating paper or temperature-indicating paint, temperature sensors using thermocouples, thermistors, etc. can also be used. . In this embodiment, a method of identifying a defective chip using a temperature sensor such as a thermocouple or a thermistor will be described.

[0067] In the third embodiment, the presence or absence of heat generation in each SiC semiconductor chip 20 is detected using a temperature sensor such as a thermocouple or a thermistor. Figure 7 It is an explanatory drawing explaining the outline of the manufacturing method of the semiconductor device of 3rd Embodiment. The manufacturing method of the semiconductor device of the third embodiment is the same as that of the first embodiment, and includes: a mounting step ( Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com