A combined automatic punching machine system and its semi-interrupted continuous punching method

An automatic punching and combined technology, applied in other manufacturing equipment/tools, metal processing, manufacturing tools, etc., can solve the problems of insufficient production capacity, unfavorable storage, low production efficiency, etc., to ensure the quality of finished products, avoid quality reduction, Produce fast effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

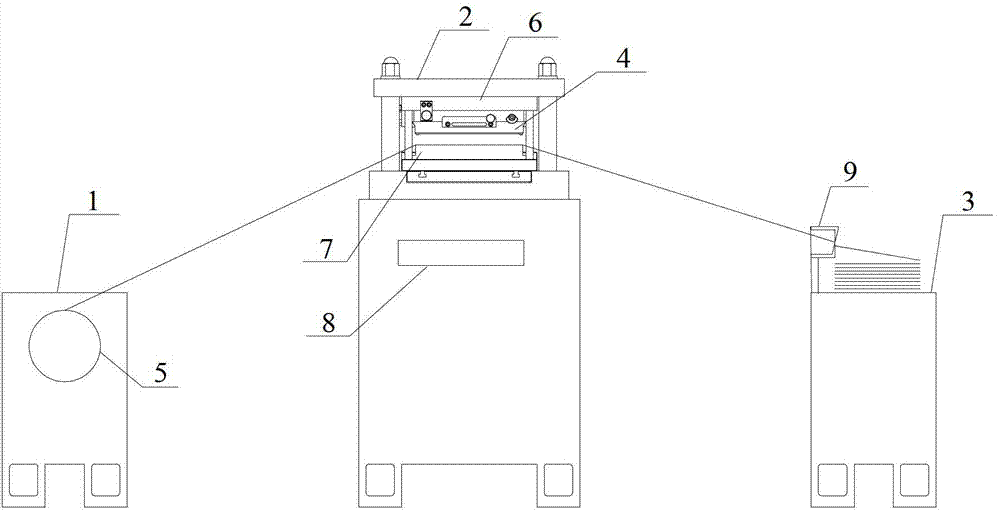

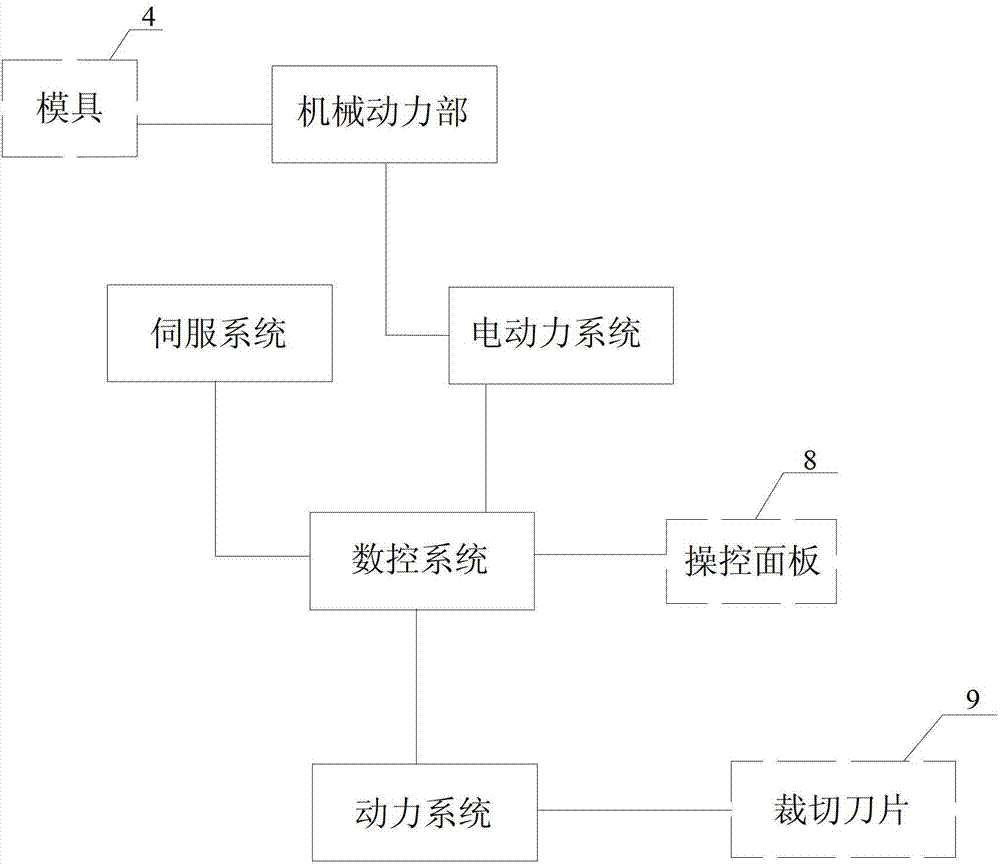

[0025] Such as Figure 1 ~ Figure 4 Shown is a combined automatic punching machine system according to an embodiment of the present invention, which includes a coil feeder 1 , a numerically controlled automatic punching machine 2 , and a numerically controlled cutting machine 3 connected in sequence. The roll feeder 1 transmits the raw materials to the CNC automatic punching machine 2, and the CNC automatic punching machine 2 punches the raw materials and transmits the punched raw materials to the CNC cutting machine 3, and the CNC cutting machine 3 cuts the received raw materials and Do automatic stacking.

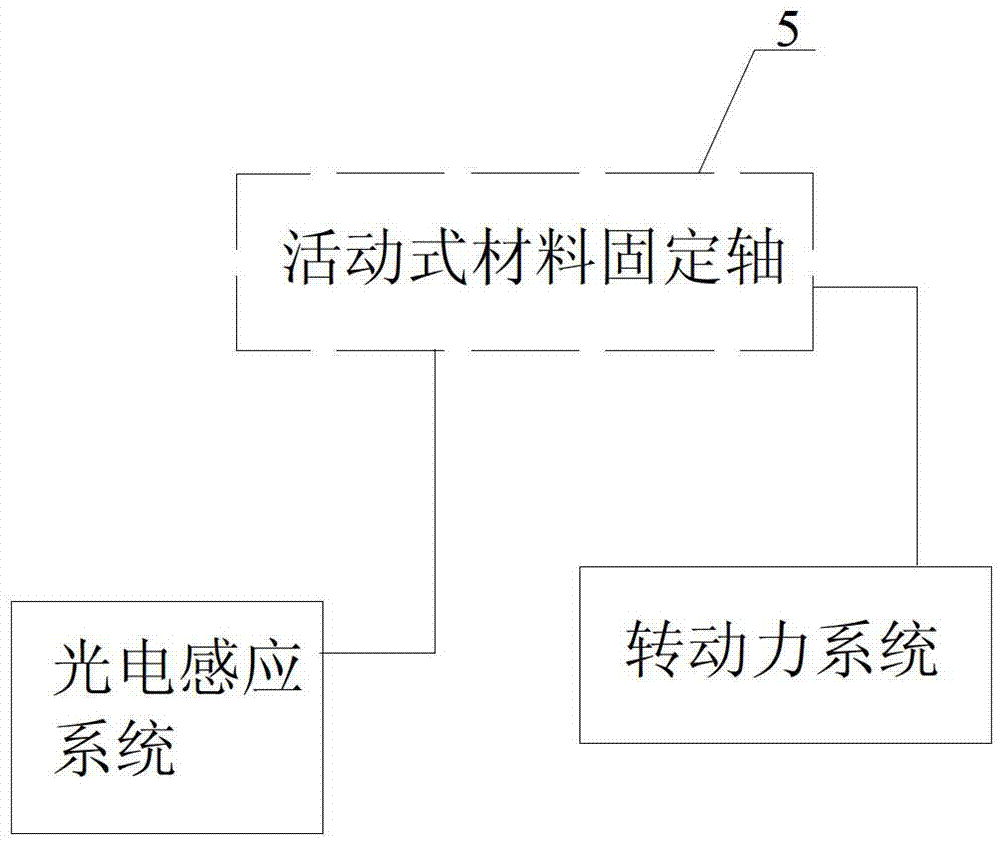

[0026] The roll feeder 1 is provided with a movable material fixed shaft 5, and the raw material rolls are placed on the movable material fixed shaft 5; at the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com