Pneumatic rotary tool

A technology of rotating tools and rotating mechanisms, applied in metal processing and other directions, can solve the problems of unfavorable order proofing and small batch production, low degree of automation, low cutting efficiency, etc., saving time for proofing and small batch production, and high degree of automation , The effect of good cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

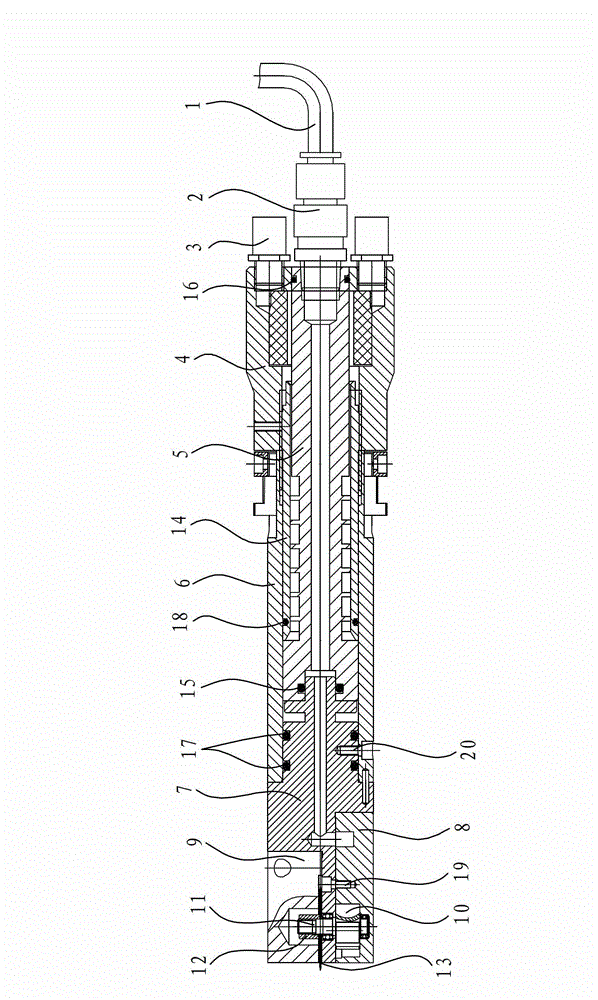

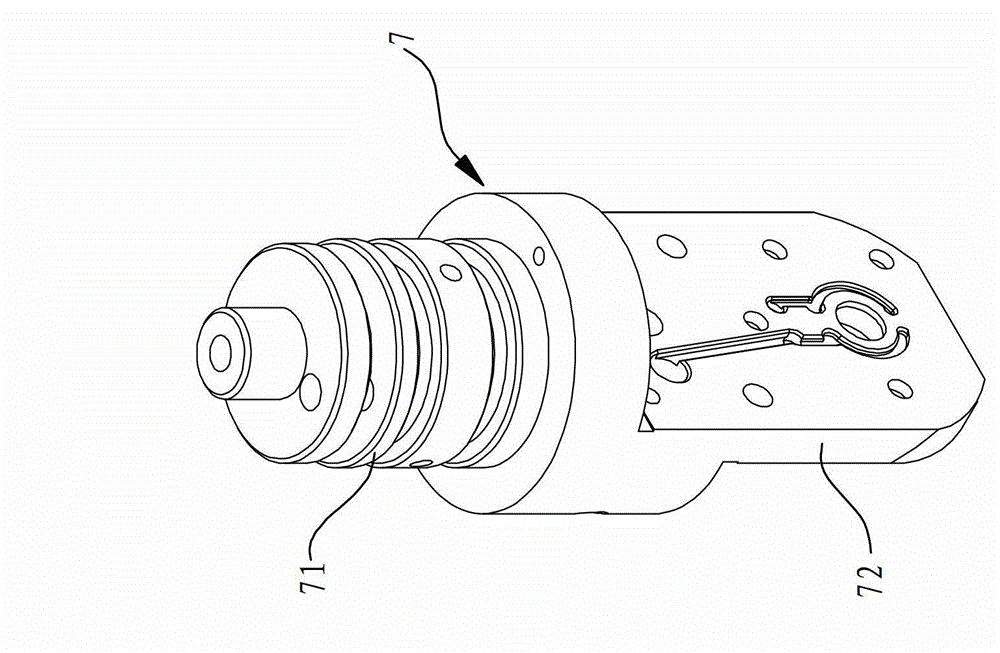

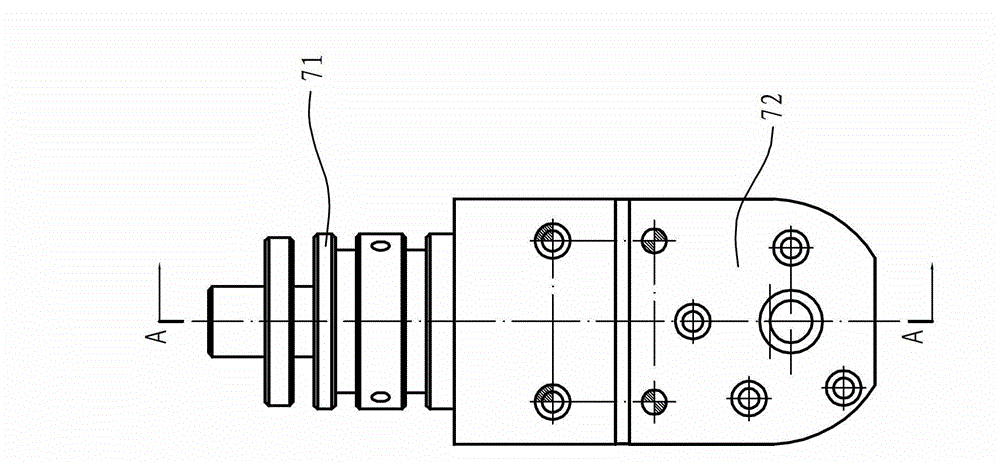

[0025] Such as Figure 1 to Figure 10 As shown, the pneumatic rotary tool in this embodiment includes a compressed air delivery mechanism, a rotary mechanism, and a tool assembly, wherein the compressed air delivery mechanism inputs compressed air to the rotary mechanism and drives the rotary parts of the rotary mechanism to rotate. After the rotary parts rotate, The cutter in the cutter assembly is driven to rotate to realize the cutting of the material. specifically,

[0026] The air delivery mechanism includes an air intake pipe 1, an air pipe joint 2, an air intake shaft 5, an air outlet shaft 14, a motor base 7 and a motor stator 8, and the air pipe joint 2 is connected between the air intake pipe 1 and the air intake shaft 5 so that the compressed air flows from the air intake The air pipe 1 is sent into the air intake end of the air i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com