Hot air type perforating machine

A technology of punching machine and hot air, applied in metal processing, etc., can solve the problems of damage to the patient's organs, pain of the patient, troublesome operation of the medical staff, etc., and achieve the effect of improving the safety performance of the use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

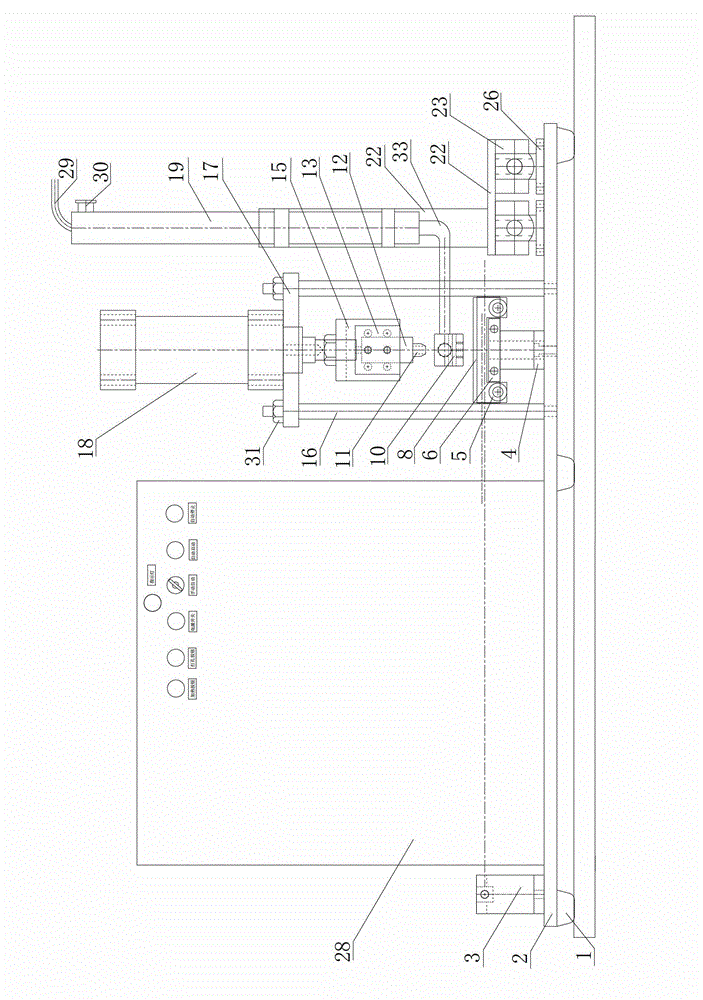

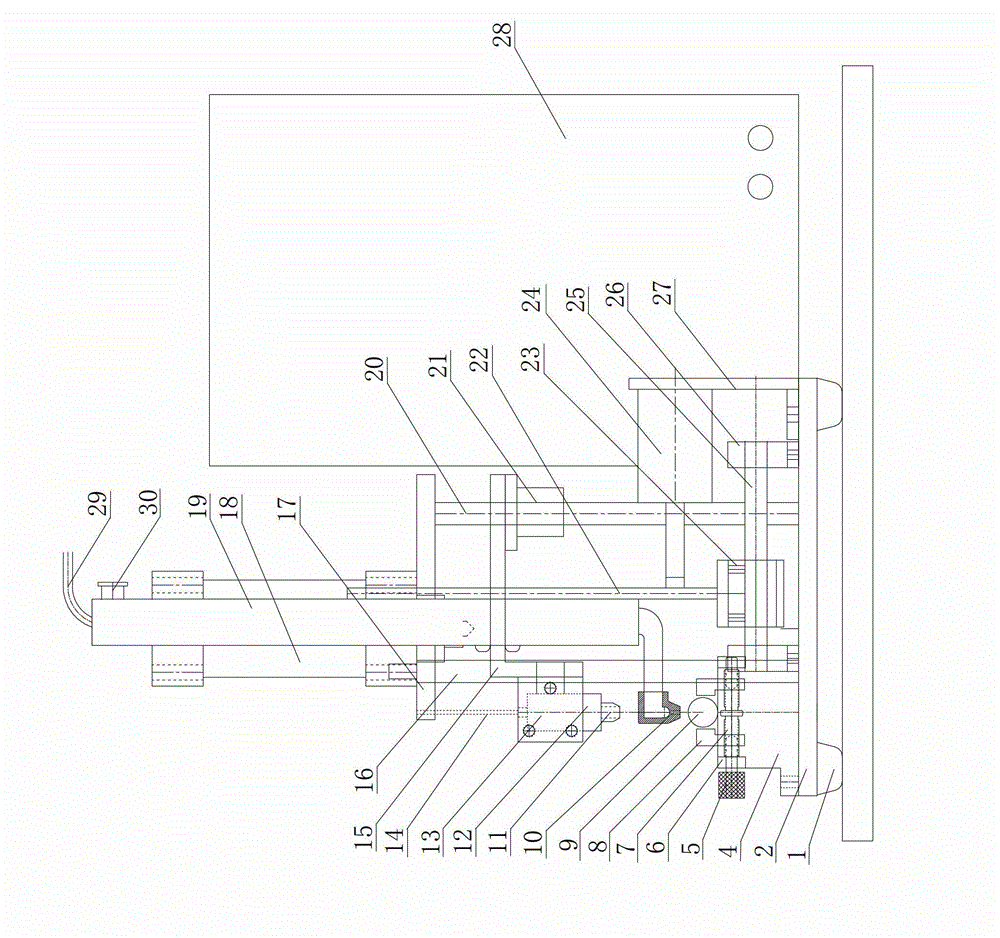

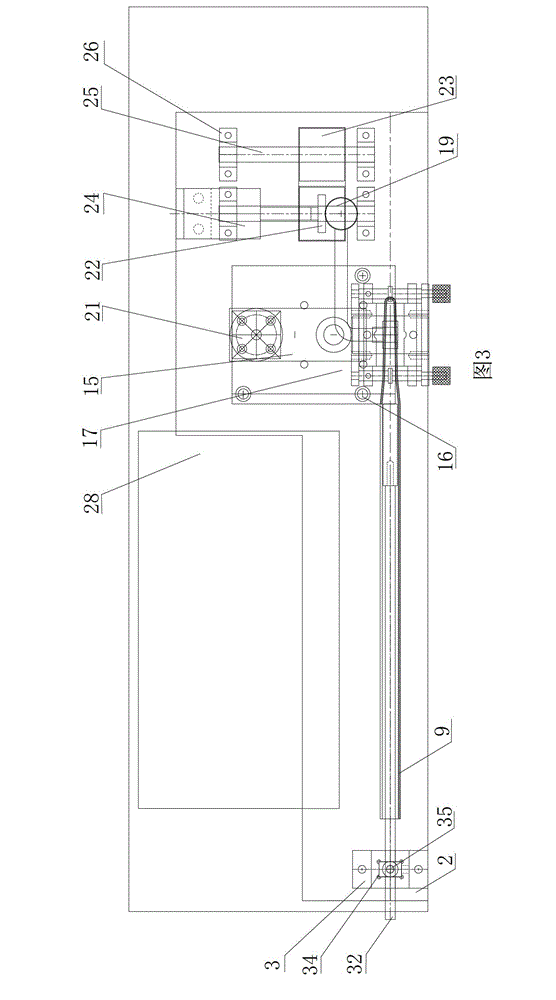

[0019] see figure 1 and figure 2 , a hot-air punching machine, including a base 2 and a rubber pad 1 fixed on its bottom, a mandrel support frame 3 and an electric control box 28 are installed on one end of the base, and the other end is installed with a clamp bracket 4 for clamping and A clamp assembly for fixing pipe fittings, a punching mechanism is arranged on the base corresponding to the top of the clamp assembly, and a heating device is also installed on the base located on one side of the punching mechanism. The clamp assembly includes: a clamp support plate 6 fixed on the base 2, a clamp 8 and an adjusting bolt 7 passing through the clamp are arranged on the clamp support plate, and two ends of the adjustment bolt are provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com