Solar cell panel lamination apparatus and lamination method

A solar cell panel and lamination device technology, applied in the direction of lamination devices, lamination, chemical instruments and methods, etc., can solve the problems of increased cost of lamination machines, difficulty in uniform heating, powerless demand, etc., and achieve high production efficiency, High quality, uniform and stable heating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the above-mentioned purposes, features and advantages of the present invention more obvious and understandable, the preferred embodiments of the present invention will be specifically cited below, together with the accompanying drawings, for a detailed description as follows:

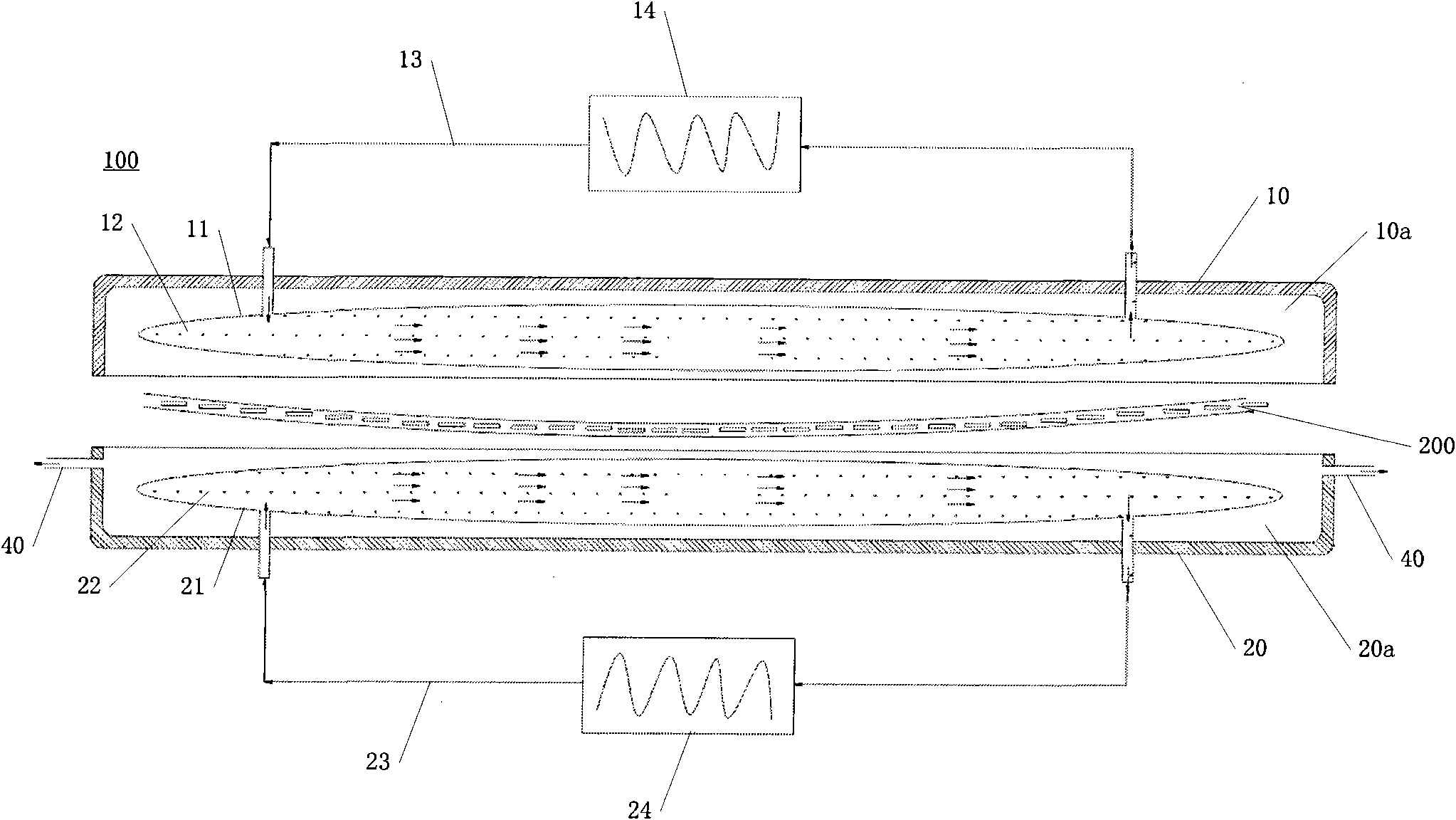

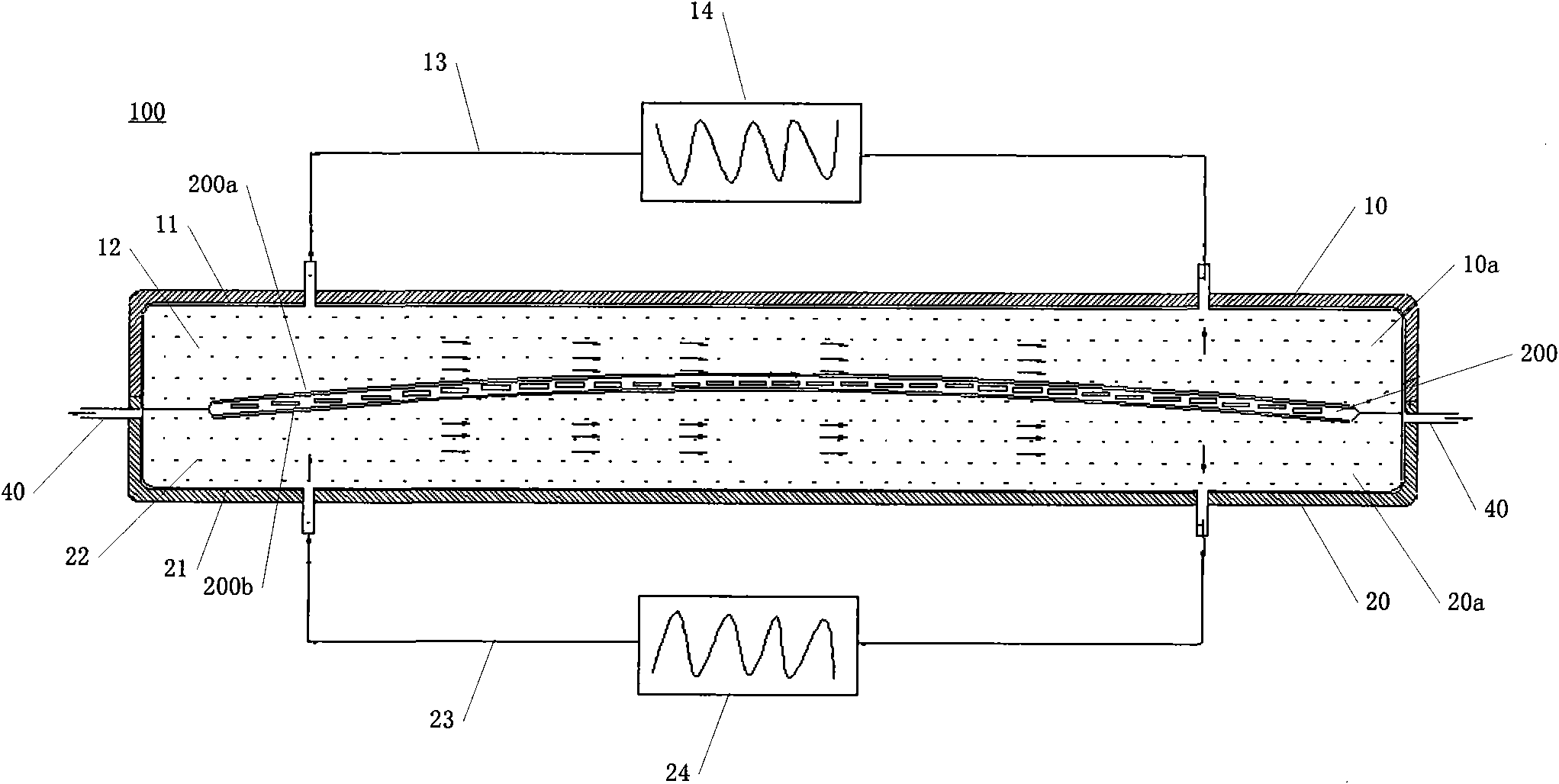

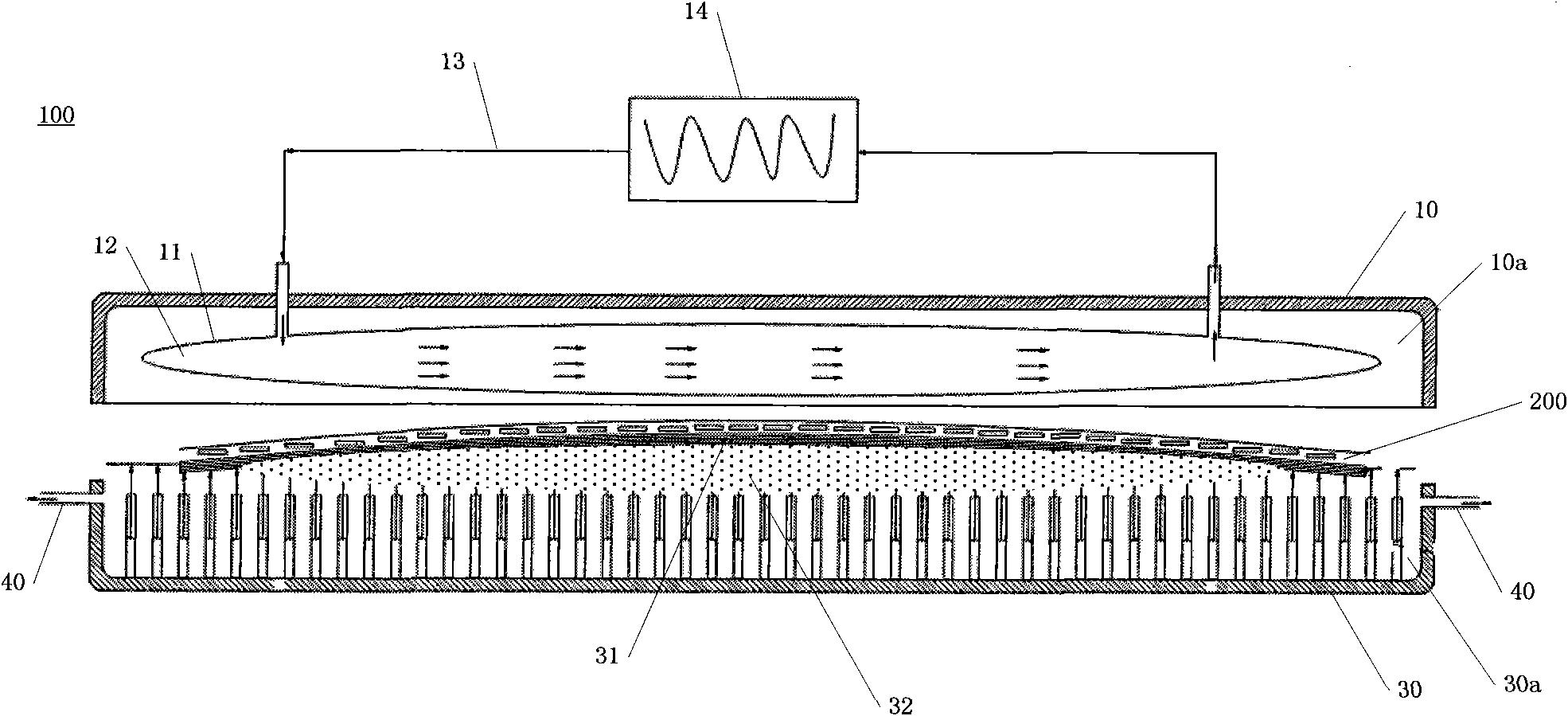

[0027] Such as figure 1 Shown is a structural schematic diagram of a specific embodiment of the present invention. In this specific embodiment, the solar cell panel lamination device 100 includes an upper chamber 10a formed by an upper cover 10 and a lower chamber 20a formed by a lower cover 20, and a first airbag 11 is arranged in the upper chamber 10a, so The first airbag 11 is filled with thermally conductive filler 12, and the first airbag 11 is connected to the first constant temperature heater 14 through the first air circulation pipeline 13; the second airbag 21 is contained in the lower chamber 20a, and the first airbag 11 The second airbag 21 is filled with a thermally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com