Overhead feeding device for crane

A feeding device and crane technology, applied in the field of feeding vehicles, can solve the problems of uneven feeding, large workshop environment pollution, dust overflow, etc., and achieve the effect of ensuring smoothness and stability, good automatic control performance, and improved work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

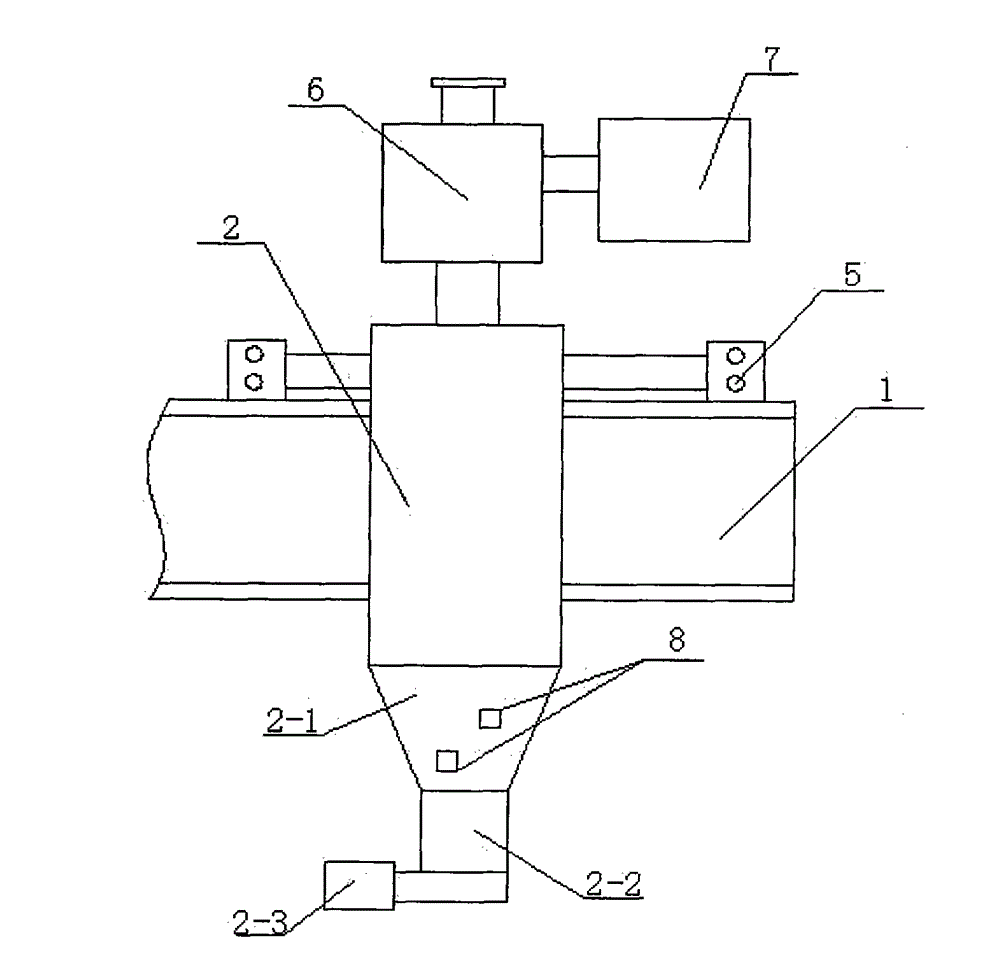

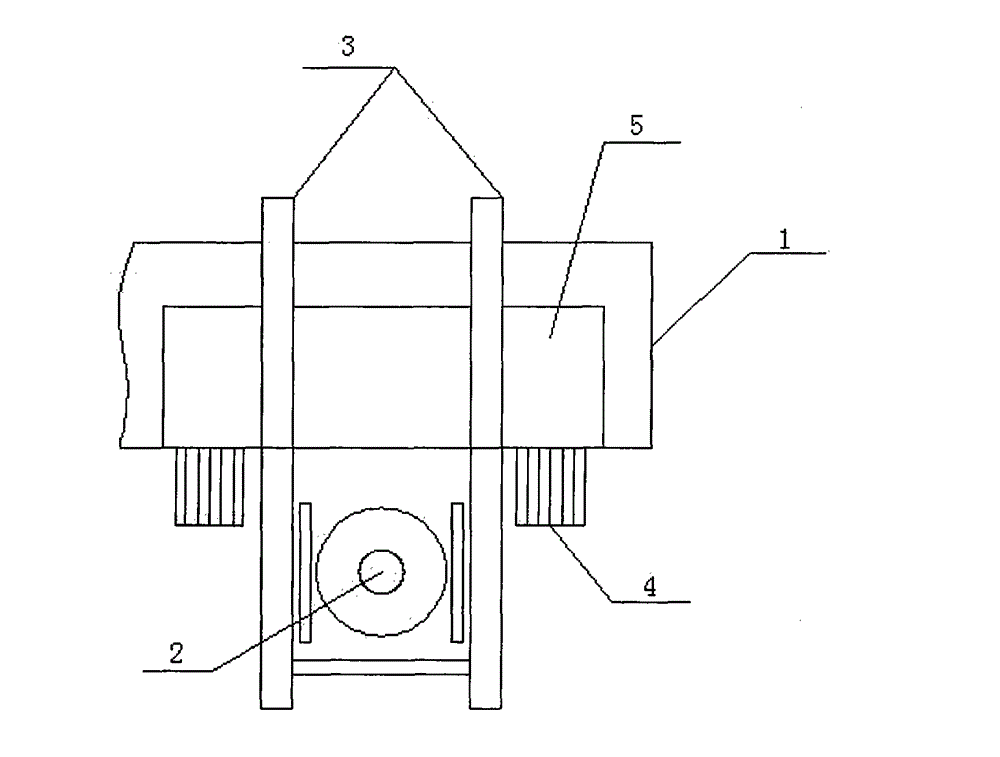

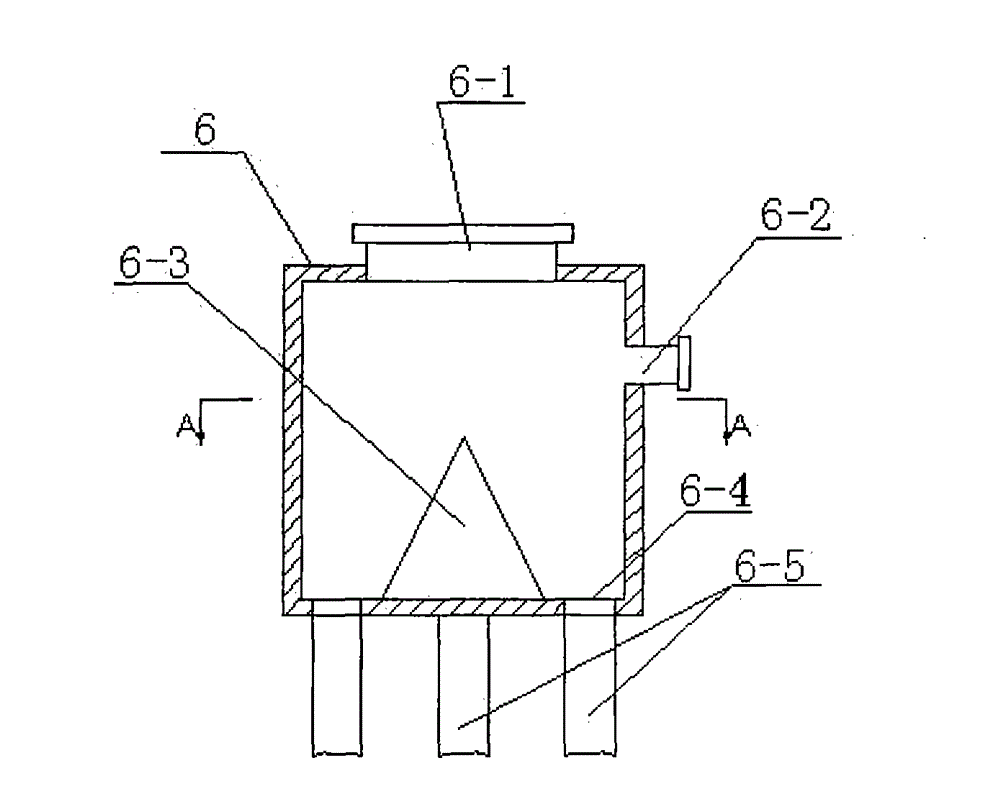

[0016] As shown in the figure, the aerial feeding device for the crane includes the frame 1, the feeding tank 2, the bracket 3, the driving mechanism 4 and the control system of the crane. Two brackets 3 parallel to each other are provided on the frame 1. One end of the bracket 3 is fixedly arranged on the support frame 5. The walking wheels at the bottom of the support frame 5 are arranged in the track groove of the frame 1, the feeding tank 2 is arranged between the two brackets 3, and the driving mechanism 4 drives the support frame 5. Horizontally reciprocating on the frame 1, a collecting box 6 and a dust collecting box 7 are provided above the feeding tank 2, and a circular feeding port 6-1 and a dust overflow port 6 are provided on the collecting box 6 2. The dust overflow port 6-2 is connected to the inlet of the dust collection box 7 through a pipeline, and a cone-shaped material dividing block 6-3 is arranged in the box body of the collecting box 6 The tip of -3 corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com