Method for improving biodegradation rate of pure iron or iron alloy and application thereof

A biodegradable, ferroalloy technology, applied in medical science, prosthesis, etc., to achieve the effect of increasing the degradation rate and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Pure iron was selected as the experimental material, the pore cross section was circular, the pore size was 0.08mm, and the pore type was through hole; the pore distribution was according to figure 1 Design, the pore spacing is 0.5mm. Pores are prepared by corrosion pore creation.

[0030] The prepared sample and the blank control sample (pure iron sample without pore structure) were subjected to immersion weight loss experiment, and the experimental parameters were as follows: immersion solution: Hank’s simulated body fluid, experimental temperature: 37°C, immersion time: 30 days.

[0031] Calculate the degradation rate results: the degradation rate of the pure iron sample with pore structure is 0.029mm / year, which is 61.1% higher than that of the blank control sample (0.018mm / year).

Embodiment 2

[0033] Select Fe-30Mn-1C alloy as the experimental material. The pore cross section is circular, the pore size is 0.10mm, and the pore type is through hole; the pore distribution is according to figure 2design with a pore spacing of 1mm. Cutting and drilling with fiber laser.

[0034] The prepared sample and the blank control sample were subjected to soaking weight loss test, and the experimental parameters were as follows: soaking solution: 0.9% NaCl solution, experimental temperature: 37°C, soaking time: 15 days.

[0035] Calculate the degradation rate results: the degradation rate of the porous structure sample is 0.43mm / year, which is 40.0% higher than that of the blank control sample (0.31mm / year).

Embodiment 3

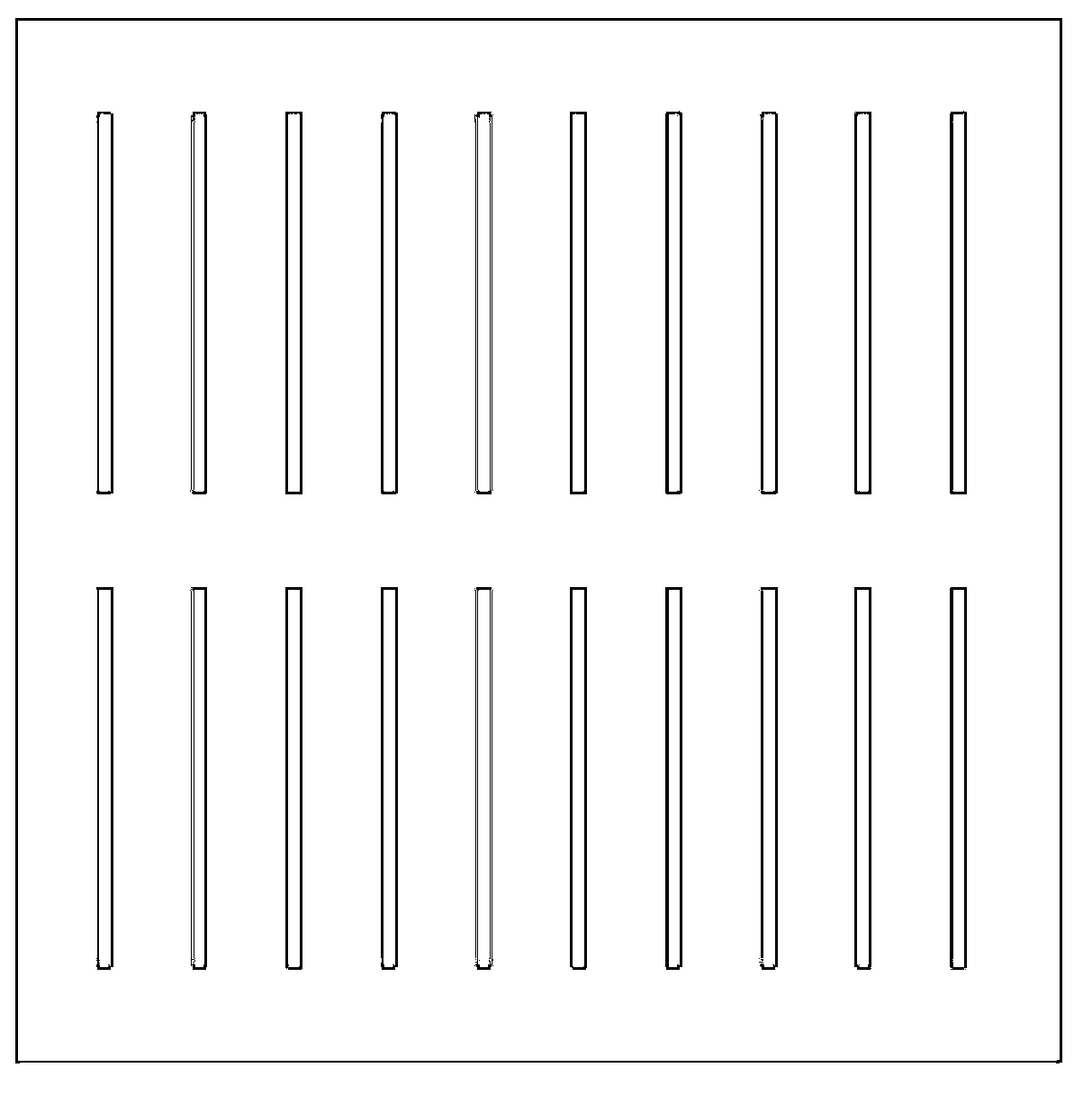

[0037] Fe-30Mn was selected as the experimental material, the pore cross section was narrow slit shape, the slit width was 0.10 mm, the slit length was 4 mm, and the pore type was through hole; the pore distribution was according to image 3 Design, the distance between the two nearest neighbors is 1mm. Holes are cut with a laser.

[0038] The prepared sample and the blank control sample were subjected to soaking weight loss test, and the experimental parameters were as follows: soaking solution: 0.9% NaCl solution, experimental temperature: 37°C, soaking time: 15 days.

[0039] Calculation of the degradation rate results: the degradation rate of the pore structure sample is 0.176mm / year, which is 51.7% higher than that of the blank control sample (0.116mm / year).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com