Noncombustible panel polystyrene sandwich board and manufacturing process thereof

A polystyrene and sandwich panel technology, applied in building components, fire protection, etc., can solve the problems of delaying construction period, reducing construction efficiency, and difficult construction of fireproof boards, and achieves the effect of good heat preservation and fast and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

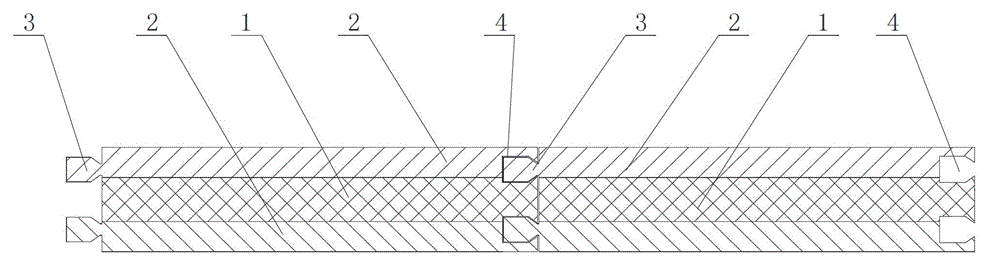

[0031] Such as figure 1 As shown, a non-combustible panel polystyrene sandwich panel includes a main body 1, a non-combustible layer 2 is provided on the upper and lower surfaces of the main body 1, and a connecting part is provided on the side of the main body.

[0032] In this embodiment, the body is a core board made of EPS or XPS polystyrene material. The non-combustible layer is composed of non-combustible panels that are attached to the upper and lower surfaces of the core board. In this embodiment, the non-combustible panel is a BM fireproof board. The non-combustible panel and the core board are bonded together through an adhesive layer.

[0033] The connection part includes a socket end and a socket end. The socket end and the socket end are arranged on both sides of the core board respectively, the socket end includes two sockets 3 , the socket end includes two sockets 4 , and the two sockets and the two sockets cooperate with each other. Two sockets and sockets ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com