Method for building bushing inner-sieve-tube artificial natural gas migration passage between gas reservoirs

A migration channel and screen-type technology, which is applied in earthwork drilling, wellbore/well components, production fluids, etc., can solve the problems of increased investment in drilling, completion and production facilities, impact on economic benefits, waste of natural gas resources, etc. Achieve the effects of saving investment and operating costs, increasing economic recovery, and reducing completion cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

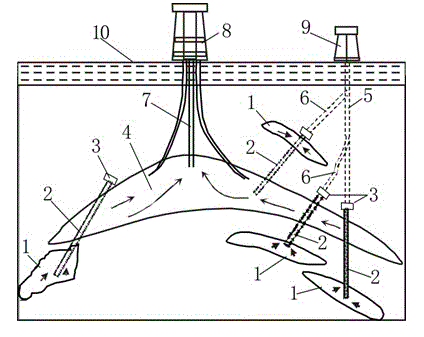

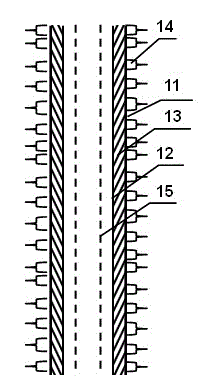

[0032] as attached figure 1 As shown, the method for establishing the screen-in-casing type man-made natural gas migration channel between gas reservoirs includes the following steps:

[0033] 1) In the middle and early stage of the development of the developed offshore gas field, the physical property of the reservoir sand body is selected from the gas field. According to the distribution range of body space and the drilling capacity of drilling ship 9, select the undeveloped gas reservoir 1 suitable for the development of the present invention in or around the developed gas field, that is, small-scale gas reservoir or abnormally high pressure gas reservoir or low permeability gas reservoir or high CO content 2 Gas reservoir;

[0034] 2) According to the selected gas reservoirs to be developed 1 above, that is, small-scale gas reservoirs or abnormally high-pressure gas reservoirs or low-permeability gas reservoirs or high CO content 2 The spatial relationship between the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com