Engine hydraulic energy and power conversion device

A power conversion and engine technology, applied in the direction of machines/engines, mechanical equipment, etc., can solve the problems of poor power transmission reliability, poor ignition stability, unfixed top dead center, etc., and achieve high-efficiency power conversion within the machine, fast power transmission, and principle reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Further description will be given below through the embodiments and in conjunction with the accompanying drawings.

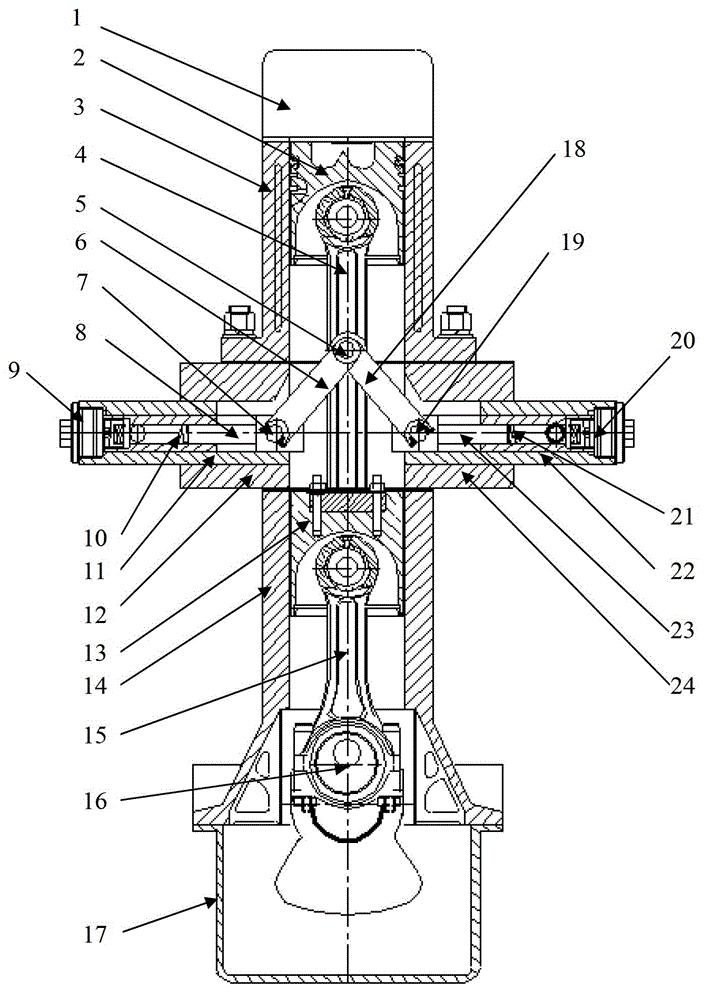

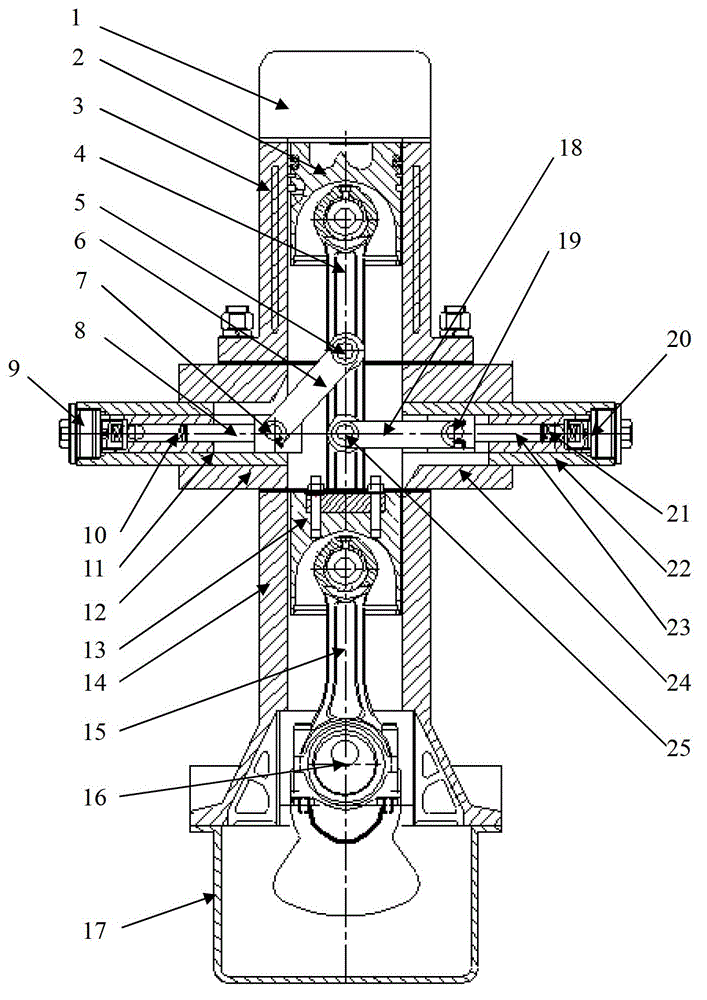

[0010] The main structure of this embodiment includes a cylinder head 1, a working piston 2, a cylinder block 3, an upper connecting rod 4, a first, a bifurcated rod pin 5 and 25, a first, a bifurcated rod 6 and 18, a first , two plunger connecting pins 7 and 19, the first and second plunger pumps 9 and 20, the first and second plungers 8 and 23, the first and second plunger springs 10 and 21, the first and second pump bodies 11 and 22. First and second pump seats 12 and 24, guide piston 13, lower body 14, connecting rod 15, crankshaft 16 and oil pan 17; composed of cylinder head 1, cylinder block 3, lower body 14 and oil pan 17 The body assembly, the cylinder block 3 and the lower body 14 are made into an integrated structure, just like the cylinder head 1 of a traditional engine is installed on the cylinder block 3; the oil pan 17 is fixedly installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com