Ceramic radiator and LED (light-emitting diode) illuminating lamp adopting same

A technology of LED lighting and radiators, which is applied in lighting devices, lighting and heating equipment, cooling/heating devices of lighting devices, etc., can solve the problems of shortened life, poor corrosion resistance, and high price of metal raw materials, and achieve price reduction, cost reduction, Safety performance guarantee, good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

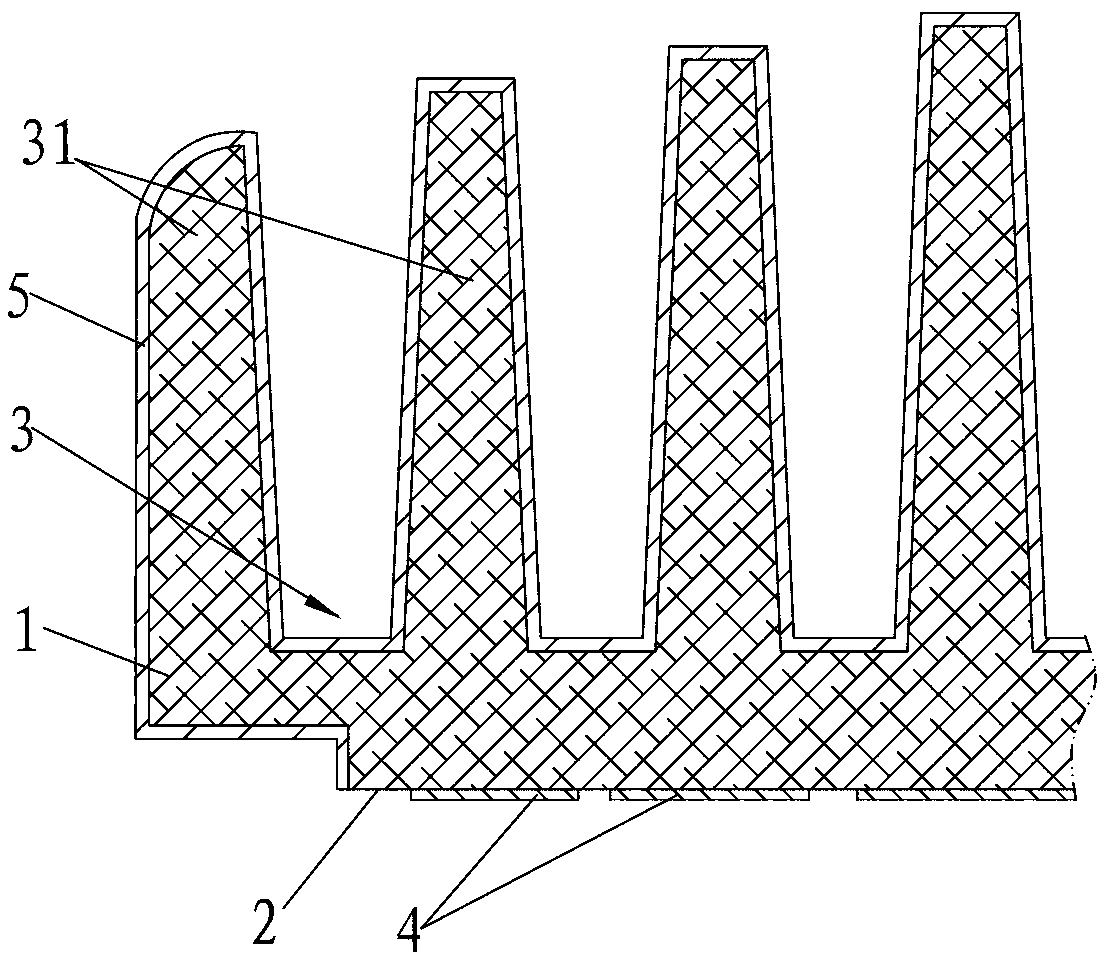

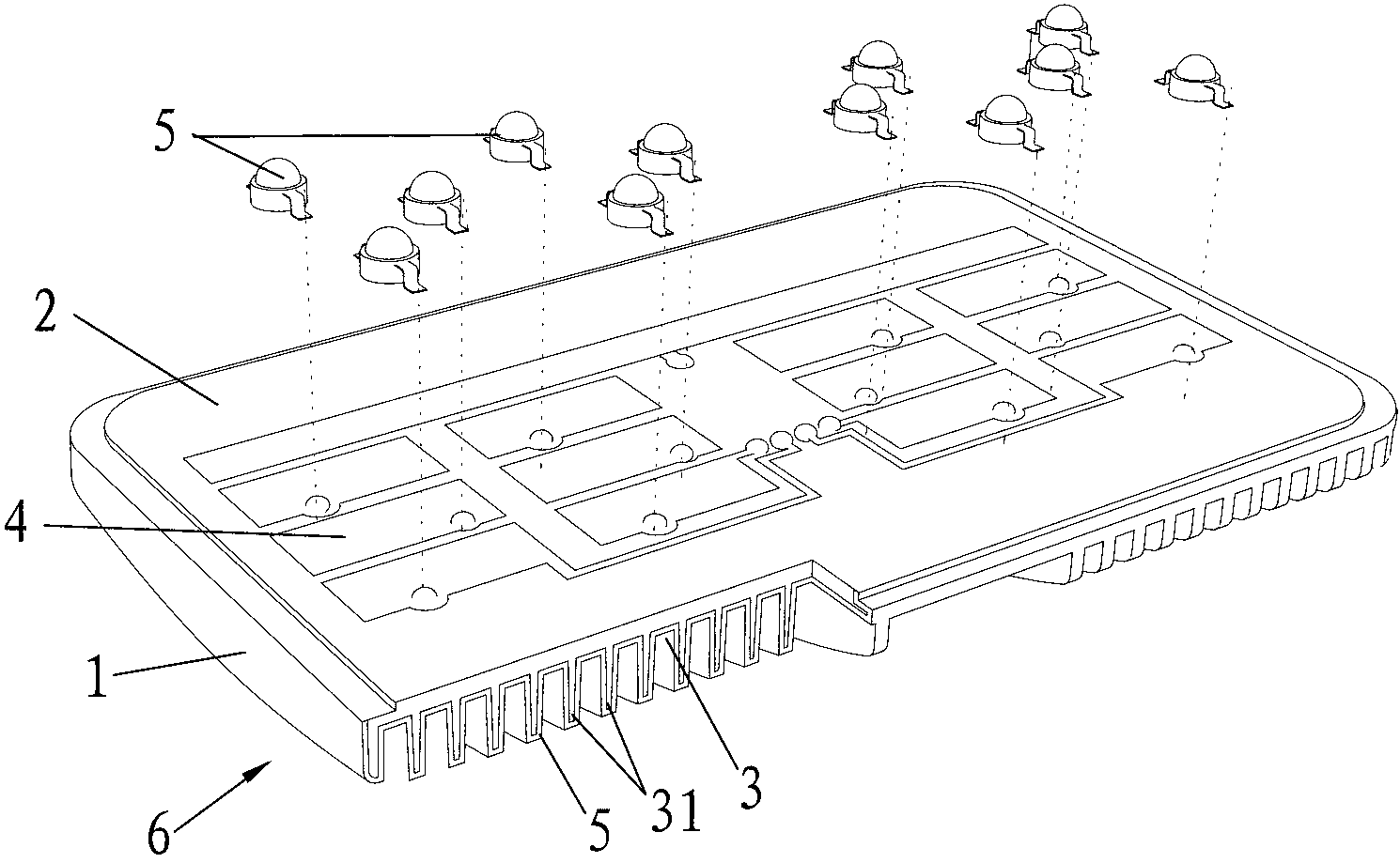

[0015] Attached below figure 1 , 2 The present invention is described further:

[0016] Such as figure 1 As shown, a ceramic heat sink, the heat sink is a ceramic integrated heat sink 1, the heat sink 1 includes a working plane 2 and a heat dissipation surface 3 arranged on the back of the working plane 2, the working plane 2 is set The LED component circuit 4, the LED component circuit 4 can be directly attached to the working plane 2 by means of printing, electroplating and post-corrosion.

[0017] In this embodiment, the heat dissipation paint 5 is coated on the heat dissipation surface 3 of the ceramic heat sink, and the heat dissipation surface 3 area is increased through the heat dissipation paint 5, or the heat radiation mode and capacity are changed, and the heat conduction and heat dissipation performance of the heat sink are improved.

[0018] In order to enhance the heat dissipation effect, heat dissipation fins 31 are arranged on the heat dissipation surface 3, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com