Device for supplying additional in-situ stress to film and measuring method for stress value thereof

An in-situ stress and stress value technology, applied in the direction of measuring force, measuring device, and mechanical device, can solve the problems of large sample size, not intuitive enough, complex structure, etc., and achieve the effect of intuitive reading, simple structure and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

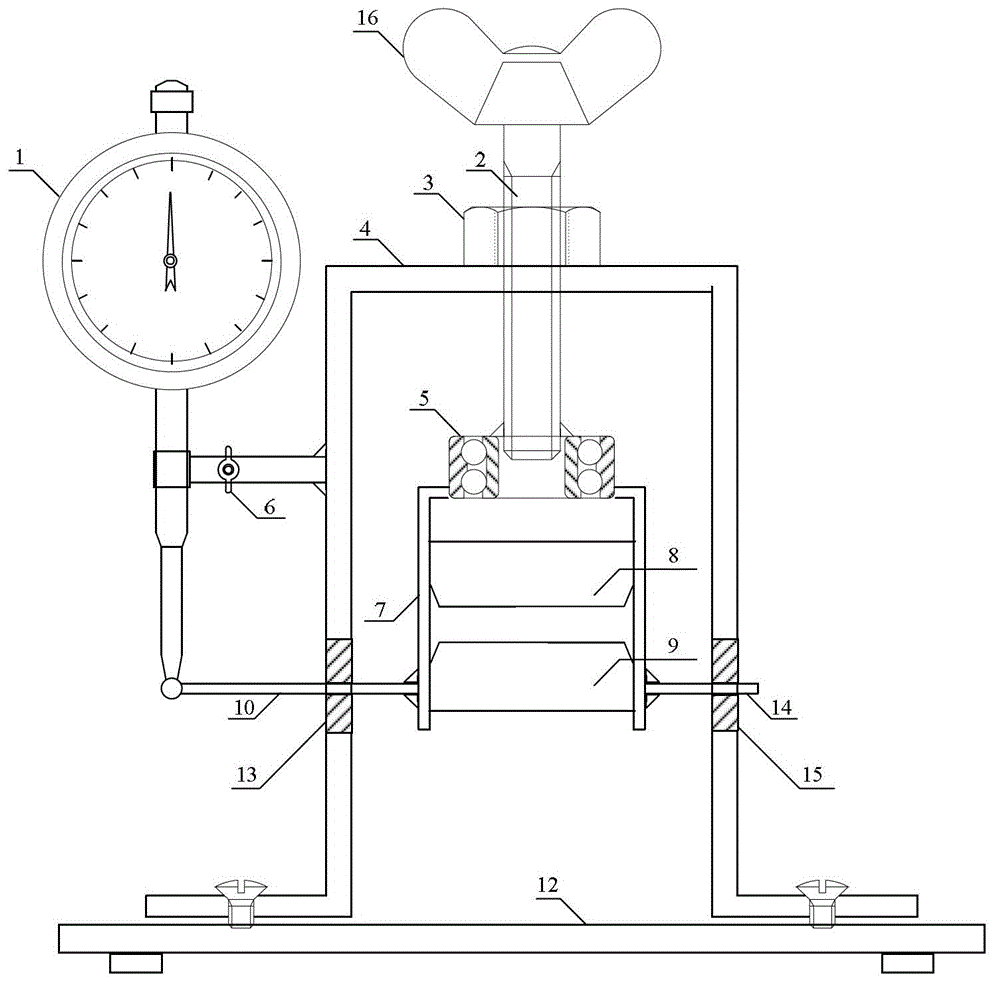

[0035] The technical content of the present invention will be described in detail below in conjunction with the accompanying drawings.

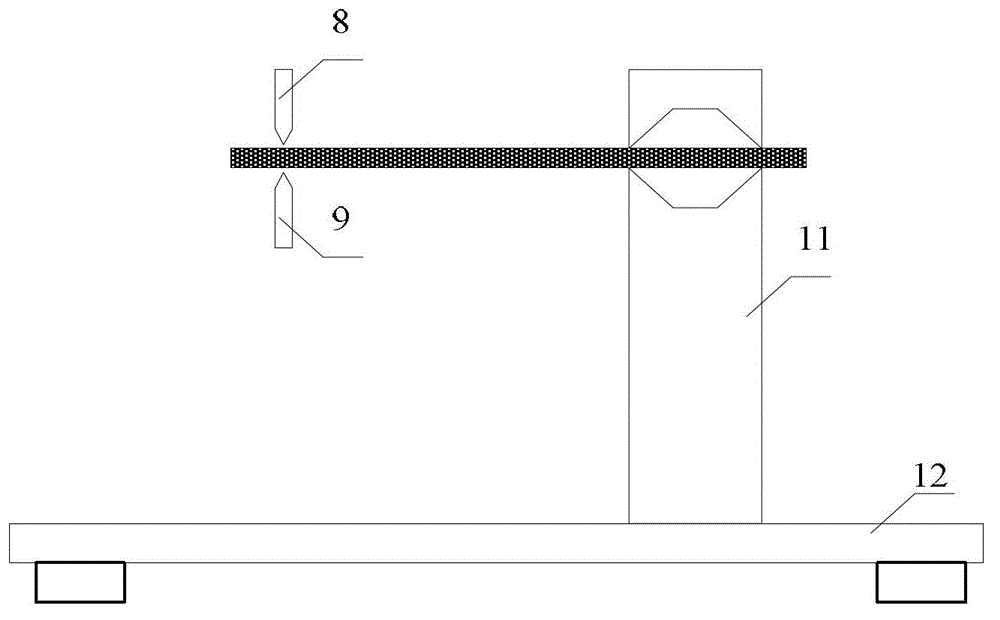

[0036] Such as figure 1 with figure 2As shown, a kind of device of the present invention provides external stress in situ to film, comprises dial gauge 1, screw rod 2, nut 3, support 4, bearing 5, dial gauge fixed connecting rod 6, metal blade holder 7, Upper metal blade 8 , lower metal blade 9 , connecting rod 10 , holder 11 and base 12 . The top of the bracket 4 is provided with a through hole, the nut 3 is fixedly connected to the top surface of the bracket 4, and the nut 3 and the through hole of the bracket 4 are coaxial. The screw rod 2 cooperates with the nut 3 , and the top end of the screw rod 2 is located outside the bracket 4 , and the bottom end of the screw rod 2 is located inside the bracket 4 . The screw rod 2 passes through the through hole on the top of the bracket 4 and the nut 3 at the same time. The bearing 5 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com