Paraffin sectioning method for peanut seeds

A technology of paraffin sectioning and seed kernels, which is applied in the preparation of test samples, etc., can solve the problems of unsatisfactory paraffin sectioning effects and no reports, and achieve the effect of easy popularization and application and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

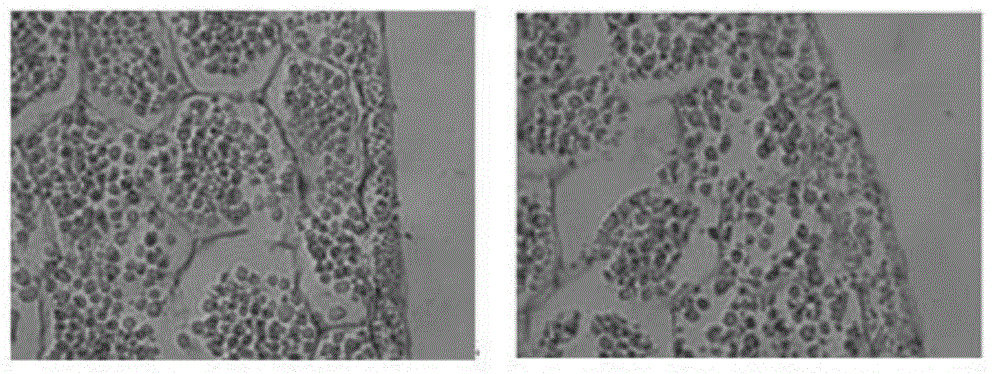

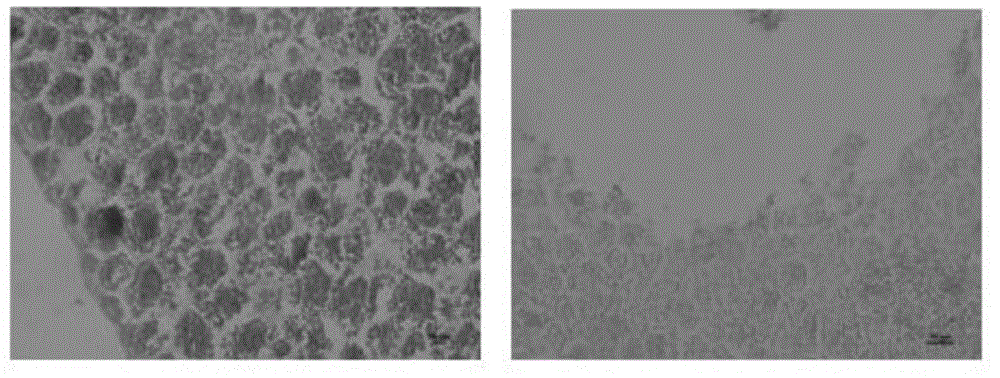

Image

Examples

Embodiment 1

[0051] 1. Material: Take the peanut kernels of resistant and susceptible peanut varieties J11 and Jinhua 1012 8 days (days) after Aspergillus flavus infection, separate two cotyledons, and then cross-cut them.

[0052] 2. Fixation: Fix commonly used glutaraldehyde with electron microscope samples, the volume concentration of glutaraldehyde is 5%, double distilled water as solvent, put peanut kernel slices into fixative, and replace fixative 3 times during fixation .

[0053] 3. Dehydration: The samples are dehydrated by ethanol. The specific dehydration procedures are: 80% ethanol for 50 minutes, 95% ethanol for 45 minutes, and 100% ethanol for 45 minutes. Each step of the dehydration process is two times. Before the sample is dehydrated, the sample is wrapped with section paraffin at 54~56℃. Buried positioning is convenient for future operations.

[0054] 4. Transparency: Use 1:1 (volume ratio) xylene:ethanol transition method. The specific transparent process is as follows: 1:1 xy...

Embodiment 2

[0061] 1. Material: Take the peanut kernels of resistant and susceptible peanut varieties J11 and Jinhua 1012 2d, 4d, 6d, 8d, 10d after Aspergillus flavus infection, separate two cotyledons, and then cross-cut them.

[0062] 2. Fixation: Fix the commonly used glutaraldehyde with the electron microscope sample, the volume concentration of glutaraldehyde is 5%, double distilled water as the solvent, put the peanut kernel slices into the fixative, and replace the fixative 3 times during the fixation process .

[0063] 3. Dehydration: The samples are dehydrated by ethanol. The specific dehydration procedures are: 80% ethanol for 50 minutes, 95% ethanol for 45 minutes, and 100% ethanol for 45 minutes. Each step of the dehydration process is performed twice. Before the sample is dehydrated, the sample is wrapped in paraffin at 54-56°C. Buried positioning is convenient for future operations.

[0064] 4. Transparency: 1:1 (volume ratio) xylene:ethanol transition method is adopted. The speci...

Embodiment 3

[0071] 1. Material: Take the peanut kernels of resistant and susceptible peanut varieties J11 and Jinhua 1012 2d, 4d, 6d, 8d, 10d after Aspergillus flavus infection, separate two cotyledons, and then cross-cut them.

[0072] 2. Fixation: Fix commonly used glutaraldehyde with electron microscope samples, the volume concentration of glutaraldehyde is 10%, double distilled water as solvent, put peanut kernel slices into fixative, and replace fixative 4 times during fixation .

[0073] 3. Dehydration: The samples are dehydrated by ethanol. The specific dehydration procedures are: 80% ethanol for 50 minutes, 95% ethanol for 45 minutes, and 100% ethanol for 45 minutes. Each step of the dehydration process is performed twice. Before the sample is dehydrated, the sample is wrapped in paraffin at 54-56°C. Buried positioning is convenient for future operations.

[0074] 4. Transparency: Adopt 1:1 (volume ratio) xylene:ethanol transition method. The specific transparent process is as follows: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com