Holographic motherboard manufacturing method and hologram based on moire fringe technology

A technology of moiré fringe and production method, which is applied in the direction of printing plate preparation, photolithographic process exposure device, optics, etc., can solve the problems such as the influence of product identification, and achieve the effect of stable product effect, strong anti-counterfeiting function, and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0040] 1) Plate making

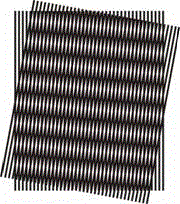

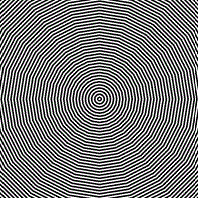

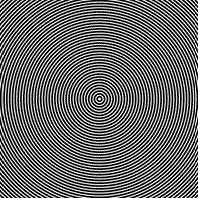

[0041] Use CorelDRAW software to design and manufacture two groups of periodic distribution of light and dark stripe grating structures, forming such as figure 2 The stripe grating shown in 1 and image 3 The stripe grating shown in 2. The fringe grating 1 and the fringe grating 2 require the same or similar fringe period, and the superimposition can produce a special moiré fringe effect.

[0042]Select fringe grating 1 as the lithographic color map structure, use Photoshop software to process the bright and dark fringes separately, and separate the light and dark fringe areas by different colors to form a lithographic color map, as shown in Figure 4 shown.

[0043] Select the stripe grating 2 as the photolithography grayscale structure. The grayscale values from 0 to 255 represent different observation angles of view, of which 128 corresponds to the front angle of view. According to the required dynamic changes, the grayscale value of the strip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com