Production execution management system and method thereof

A production execution and management system technology, applied in the field of industrial production, can solve the problems of short production order cycle, small production volume, and failure to achieve the function of MEMS system, and achieve the effect of facilitating real-time monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

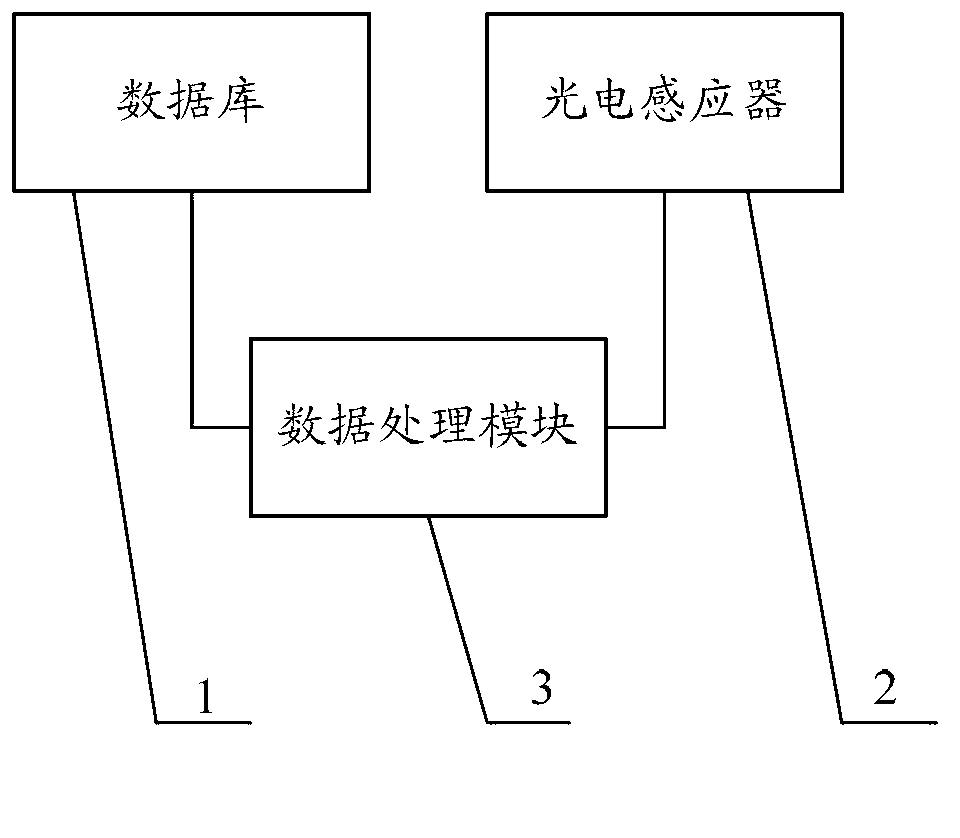

[0048] Embodiment 1 of the present invention provides a production execution force management system, see figure 1 , the system consists of:

[0049] Database 1, used to record the good product information of the product, the good product information includes the good product quantity;

[0050] The photoelectric sensor 2 is used to generate a signal to increase the number of good products when sensing the opening and closing of the mold or sensing that the product passes the preset position along the assembly line;

[0051] The data processing module 3, when receiving the signal of increasing the number of good products, increases the number of good products in the good product information corresponding to the product recorded in the database by a preset value.

[0052] The production execution management system of the present invention records the good product information of the product through the database. In this way, when the photoelectric sensor senses the opening and c...

Embodiment 2

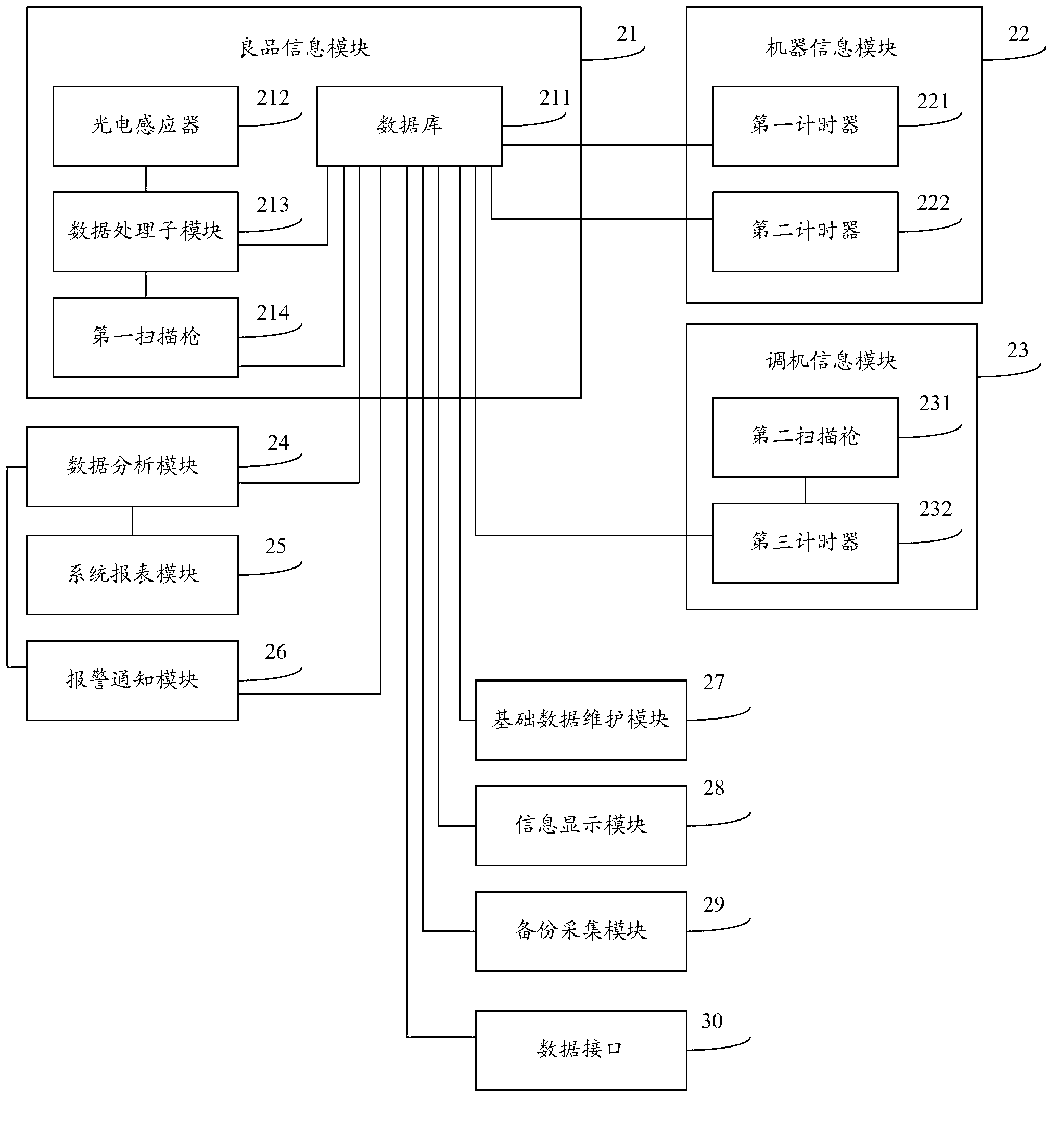

[0055] Embodiment 2 of the present invention is a specific application of the above-mentioned embodiment 1. On the basis of realizing the technical solution of the above-mentioned embodiment 1, it further adds the utilization rate and shutdown rate of the machine, as well as The realization plan of information such as the time spent on machine tuning, for details, see figure 2 Another production execution management system provided by Embodiment 2 of the present invention includes: good product information module 21, machine use information module 22, machine adjustment information module 23, data analysis module 24, system report module 25, alarm notification module 26, Basic data maintenance module 27, information display module 28, backup collection module 29, data interface 30; Specifically,

[0056] Good product information module 21, including:

[0057] The database 211 is used to record the good product information of the product, and the good product information includ...

Embodiment 1

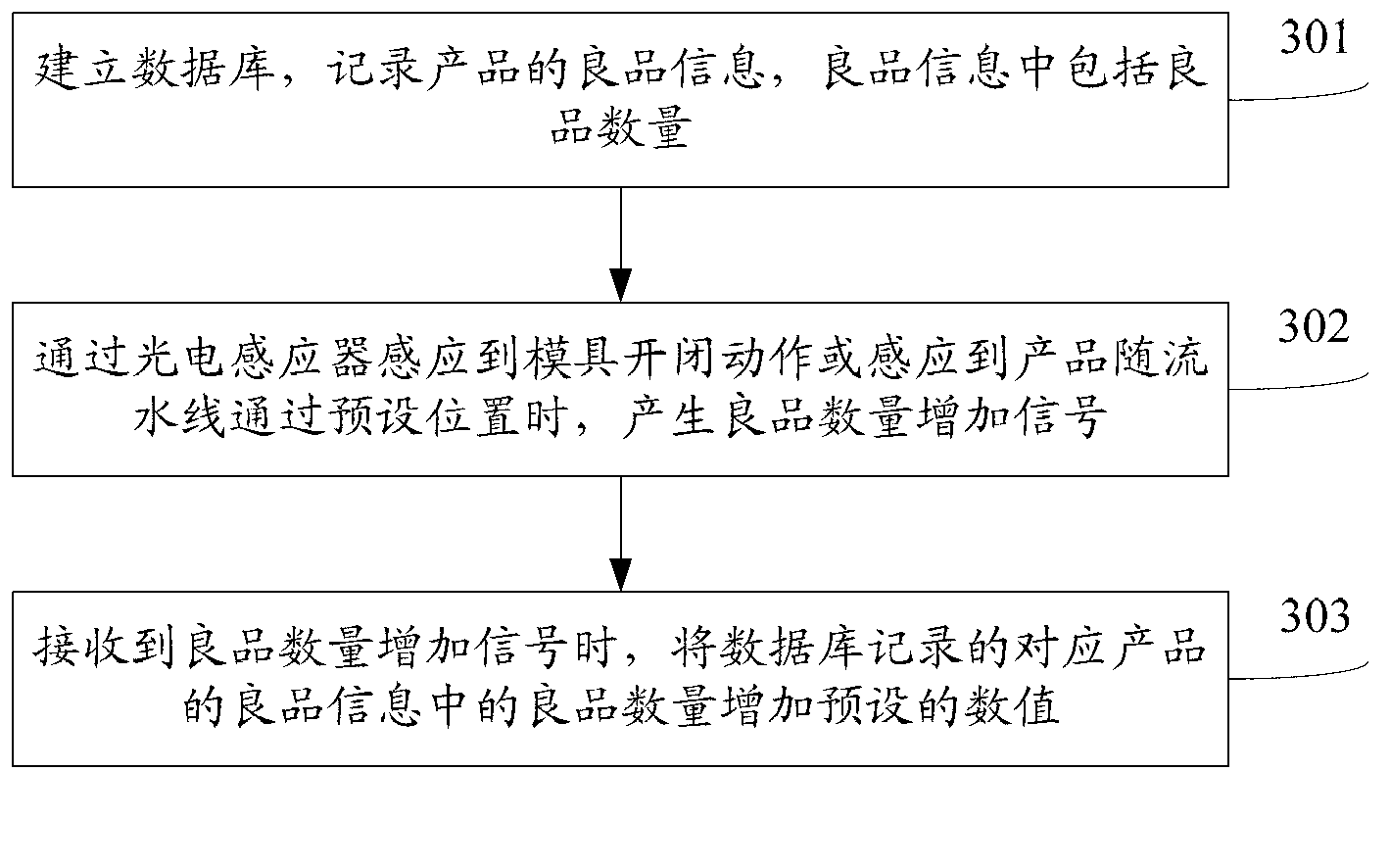

[0118] For the first embodiment, the third embodiment of the present invention provides a production execution management method, see image 3 ,include:

[0119] Step 301: Establish a database and record the good product information of the product, and the good product information includes the good product quantity;

[0120] Step 302: When the photoelectric sensor senses the opening and closing action of the mold or senses that the product passes the preset position along the assembly line, a signal for increasing the number of good products is generated;

[0121] Step 303: When the good product quantity increase signal is received, increase the good product quantity in the good product information corresponding to the product recorded in the database by a preset value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com