Gold powder and preparation method thereof

A gold powder and core technology, which is applied in the field of gold powder and its preparation, can solve the problems of iron oxide particle falling off and loss of gold luster, and achieve the effect of strong acid and alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to make the purpose, technical solution and advantages of the present invention clearer, the technical solution of the present invention will be clearly and completely described below. All other implementations obtained below fall within the protection scope of the present invention.

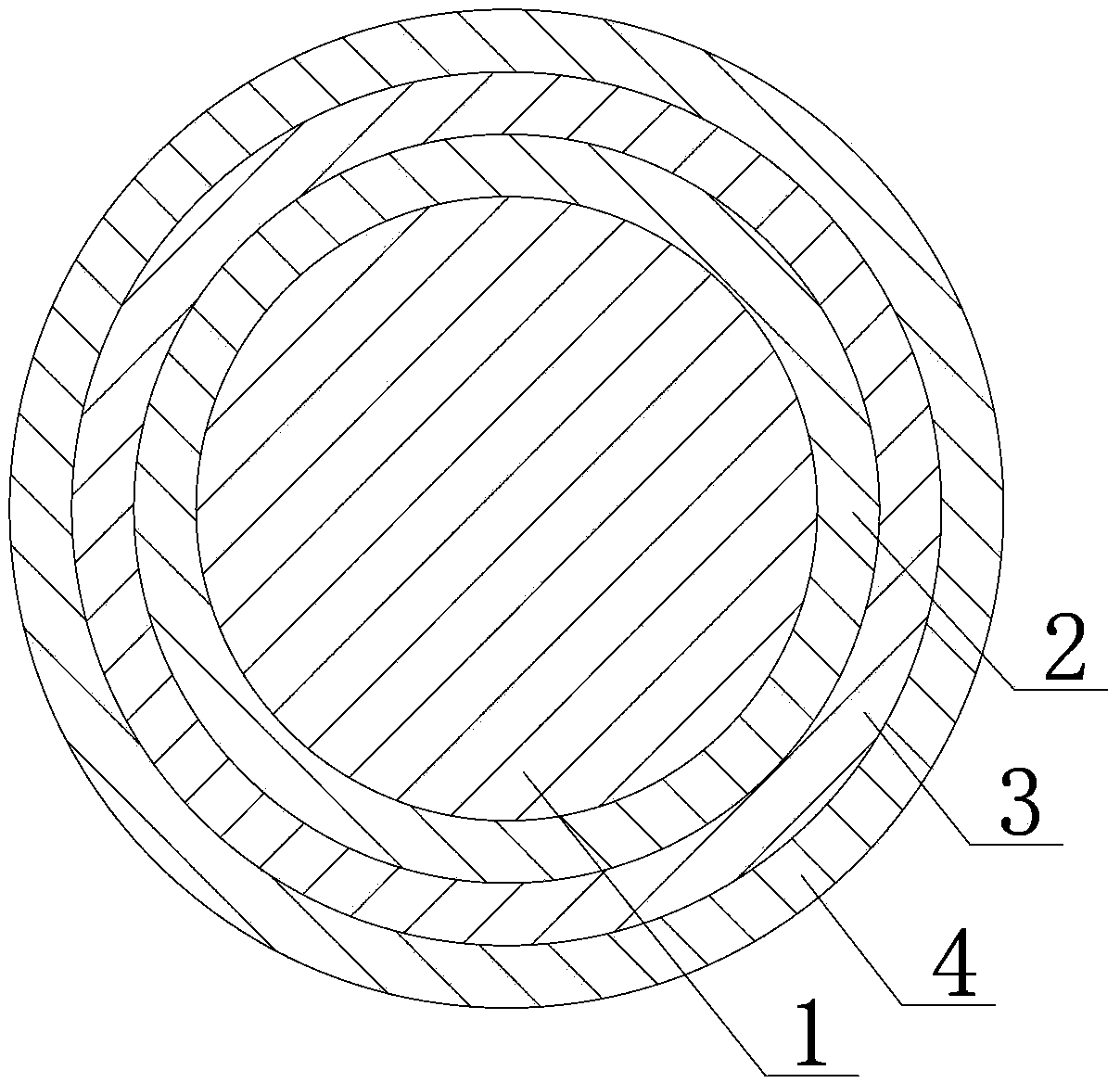

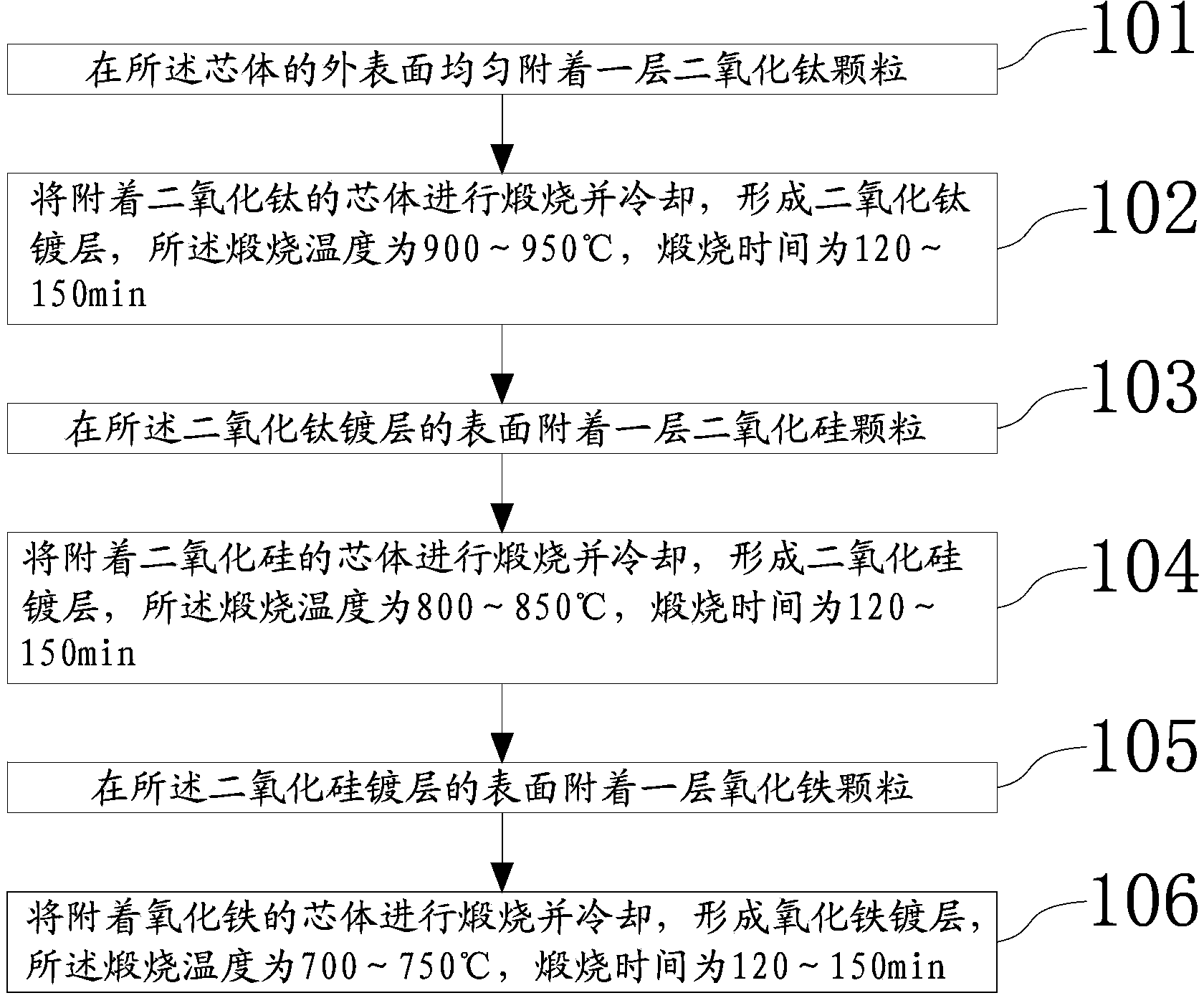

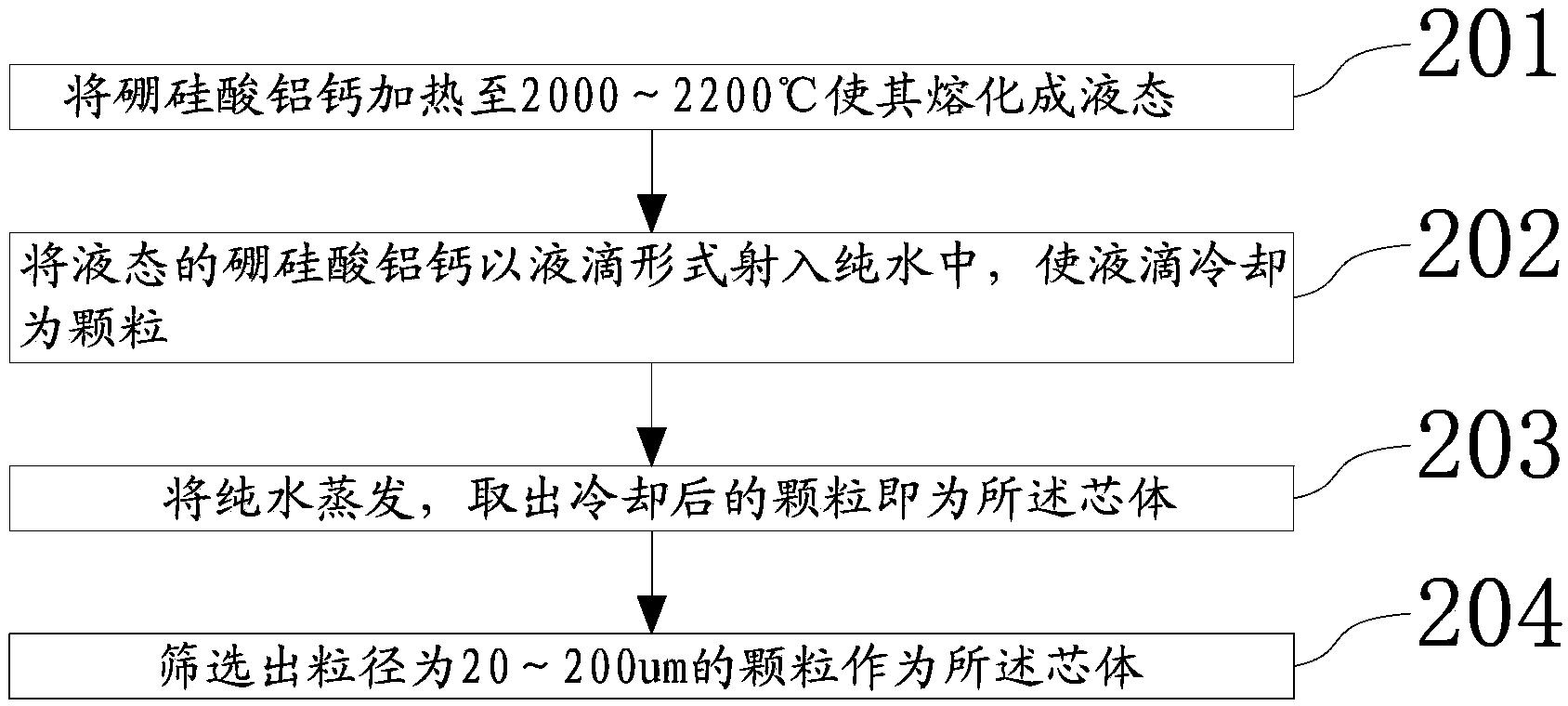

[0053] Embodiment 1 of the present invention provides a kind of gold powder, such as figure 1 As shown, it includes a core body 1; the outer surface of the core body 1 is coated with a titanium dioxide coating layer 2, a silicon dioxide coating layer 3 and an iron oxide coating layer 4 sequentially from the inside to the outside.

[0054]By coating a layer of titanium dioxide coating on the outside of the core for refracting light, and coating a layer of silicon dioxide coating on the outside of the titanium dioxide coating, and then coating iron oxide particles on the surface of the silicon dioxide coating, silicon dioxide and iron oxide The joints are so tight that neither aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com