Composite pressure-sensitive adhesive with orientation structure and electromagnetic shielding function and preparation method thereof

A composite pressure-sensitive adhesive, electromagnetic shielding technology, applied in conductive adhesives, pressure-sensitive films/sheets, film/sheet-like adhesives, etc. Path, low price, easy to paste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

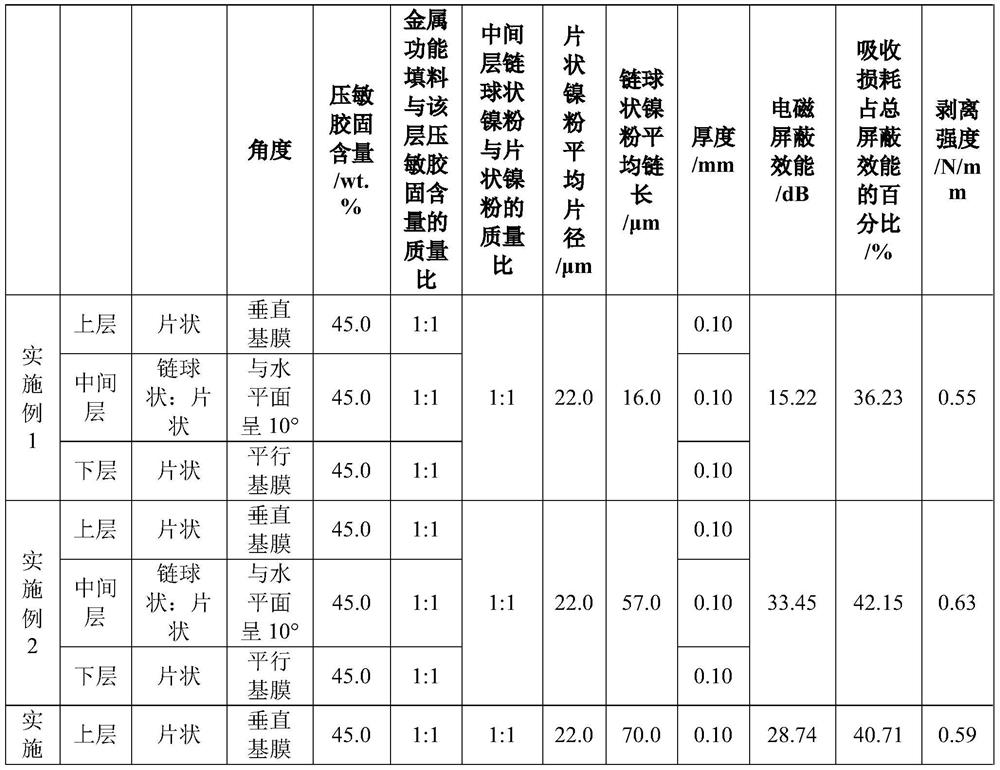

[0032] (1) Weigh two portions of 45.0 g flake nickel powder with an average sheet diameter of 22.0 μm and 100.0 g of acrylate pressure-sensitive adhesive with a solid content of 45.0 wt.%, respectively, and put them into a single-necked flask. At room temperature, mix them uniformly by mechanical stirring at a speed of 150rpm. After stirring for 1 hour, two parts of mixed solutions S1 and S3 are obtained; weigh a part of 22.5g chain-shaped nickel powder with an average chain length of Flaky nickel powder with a sheet diameter of 22.0 μm and 100.0 g of acrylate pressure-sensitive adhesive with a solid content of 45.0 wt. % were put into a single-necked flask. At room temperature, they were mixed uniformly by mechanical stirring at a rotation speed of 150 rpm, and stirred for 1 h to obtain a mixed solution S2.

[0033] (2) Put the mixtures S1, S2 and S3 into a vacuum degassing machine for 30 minutes.

[0034] (3) Put the mixed liquid S1 into the casting box of the casting machi...

Embodiment 2

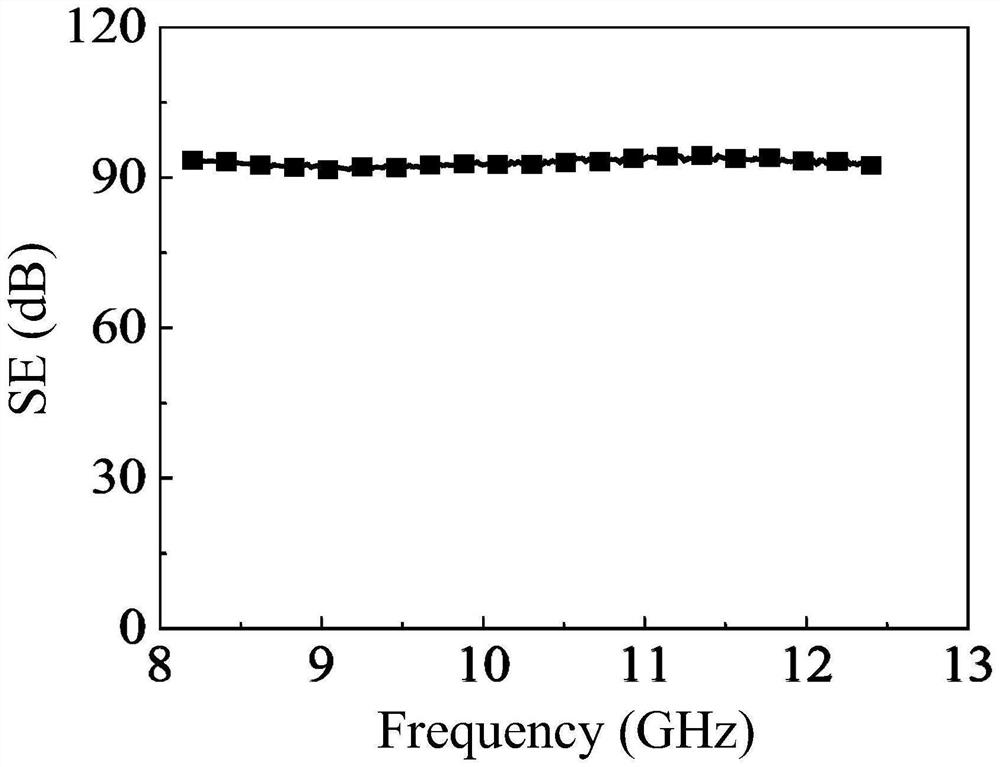

[0039] The method is the same as in Example 1, except that the average chain length of the chain-shaped nickel powder in (1) is adjusted from 16.0 μm to 57.0 μm. The electromagnetic shielding performance of the composite pressure-sensitive adhesive was tested at a frequency of 8.2-12.4GHz by using the waveguide method with a vector network analyzer. The electromagnetic shielding effectiveness of the composite pressure-sensitive adhesive can reach 33.45dB, the absorption loss accounts for 42.15% of the total shielding effectiveness, and the peel strength is 0.63N. / mm. The properties of the materials are listed in Table 1.

Embodiment 3

[0041] The method is the same as in Example 1, except that the average chain length of the chain-shaped nickel powder in (1) is adjusted from 16.0 μm to 70.0 μm. The electromagnetic shielding performance of the composite pressure-sensitive adhesive is tested at 8.2-12.4GHz using the waveguide method by a vector network analyzer. The electromagnetic shielding effectiveness of the composite pressure-sensitive adhesive can reach 28.74dB, the absorption loss accounts for 40.71% of the total shielding effectiveness, and the peel strength is 0.59N. / mm. The properties of the materials are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| polymer chain length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com