A method that can improve grinding efficiency and classification efficiency

A classification efficiency and ore grinding technology, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve the problems of low grinding and classification efficiency, small overflow fineness appreciation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

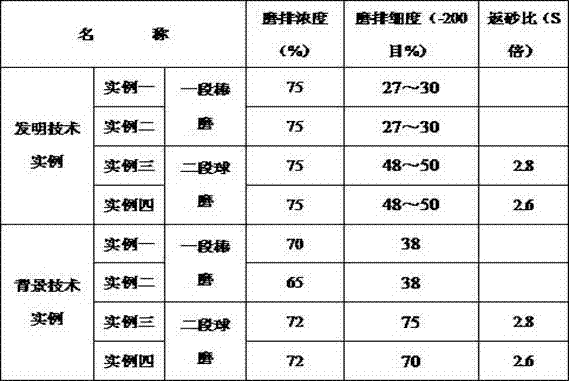

Examples

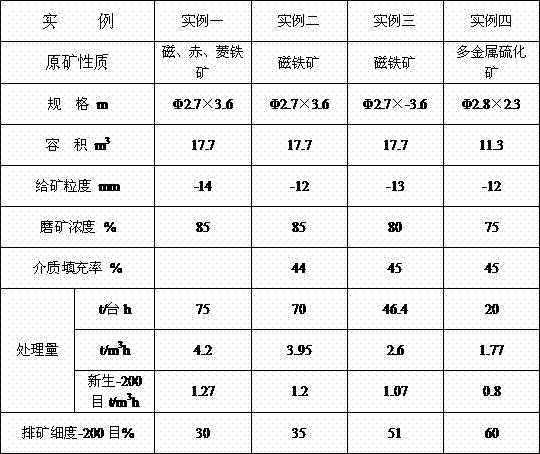

Embodiment 1

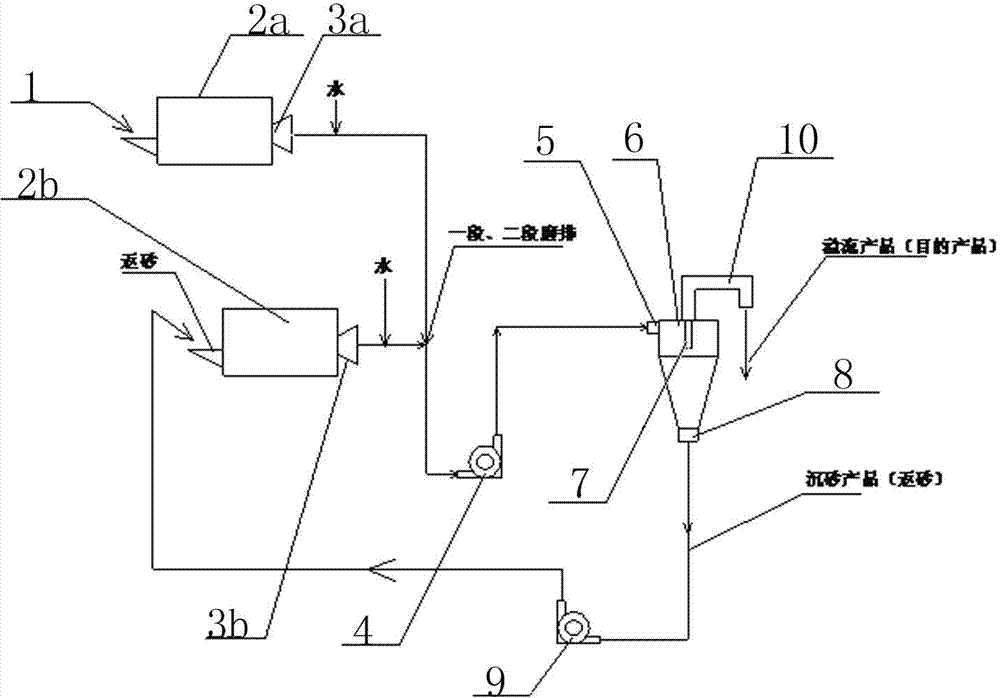

[0020] According to the method of the present invention that can improve both grinding efficiency and classification efficiency, the equipment structure used to realize the object of the present invention is: one end of the first stage rod mill 2a is the ore feeding inlet 1, and the other end is the first The ore discharge outlet 3a of the first stage of the ore mill, the ore discharge outlet 3a of the first stage of the ore mill is connected to the ore supply port 5 of the hydrocyclone through the first slurry pump 4, and the grit nozzle 8 of the hydrocyclone 6 passes through The pipeline is connected to the ore feeding inlet of the second-stage ball mill 2b, the pipeline is connected with the second slurry pump 9, and the ore discharge outlet 3b of the second-stage grinding machine passes through the first slurry pump 4 and the hydrocyclone. To connect mine port 5, the specific method is:

[0021] One end of the first stage rod mill is the ore feeding inlet, and the other en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com