Method for manufacturing desert water tower by using retired wind power blades

A technology of wind power blades and water towers, which is applied in drinking water installations, botanical equipment and methods, and wind turbines that are in line with the wind direction, and can solve the problems of difficult recycling and disposal of decommissioned wind power blades, soil and groundwater hazards, and limited absorptive capacity, etc. problem, to achieve the effect of reducing huge energy consumption, good heat absorption performance, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Combine below Figure 1-Figure 13 , the specific embodiments of the present invention will be described in detail.

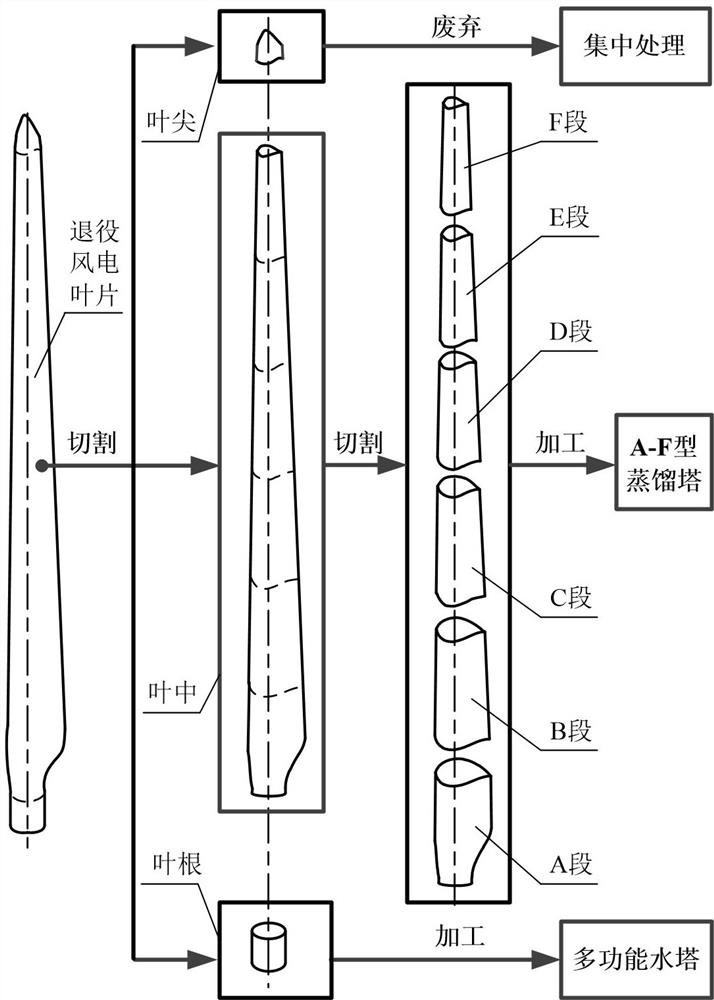

[0029] like figure 1 As shown in the figure, a method for making a desert water tower using retired wind power blades is first to cut the retired wind power blades into three parts: the root, the middle and the tip; then the middle of the leaf is further cut into A, B, C, D, E, F six sections; finally, the blade roots are processed into multi-functional water towers, A-F six sections are processed into distillation towers of different specifications, and the blade tips are discarded and handed over to the blade recycling company for centralized treatment.

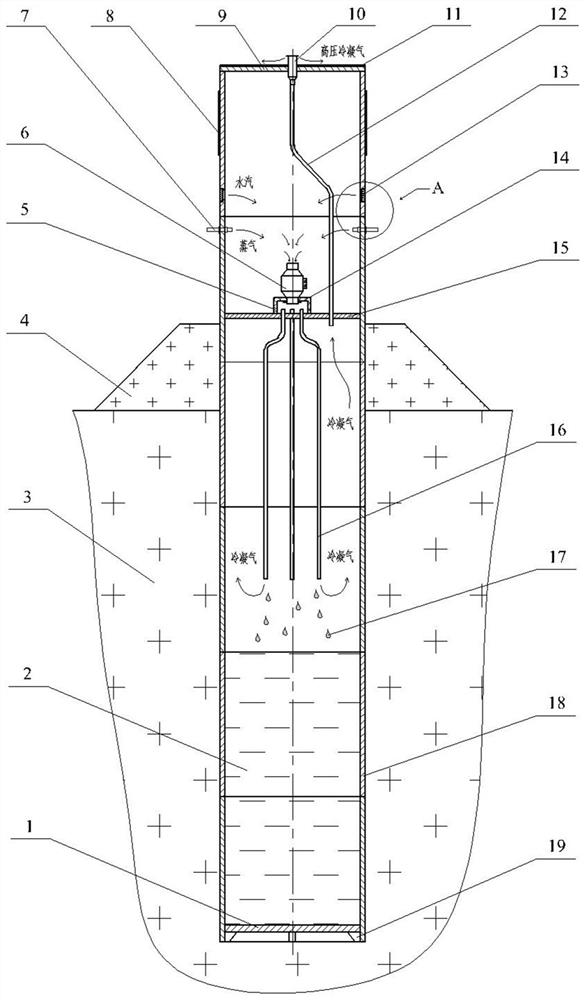

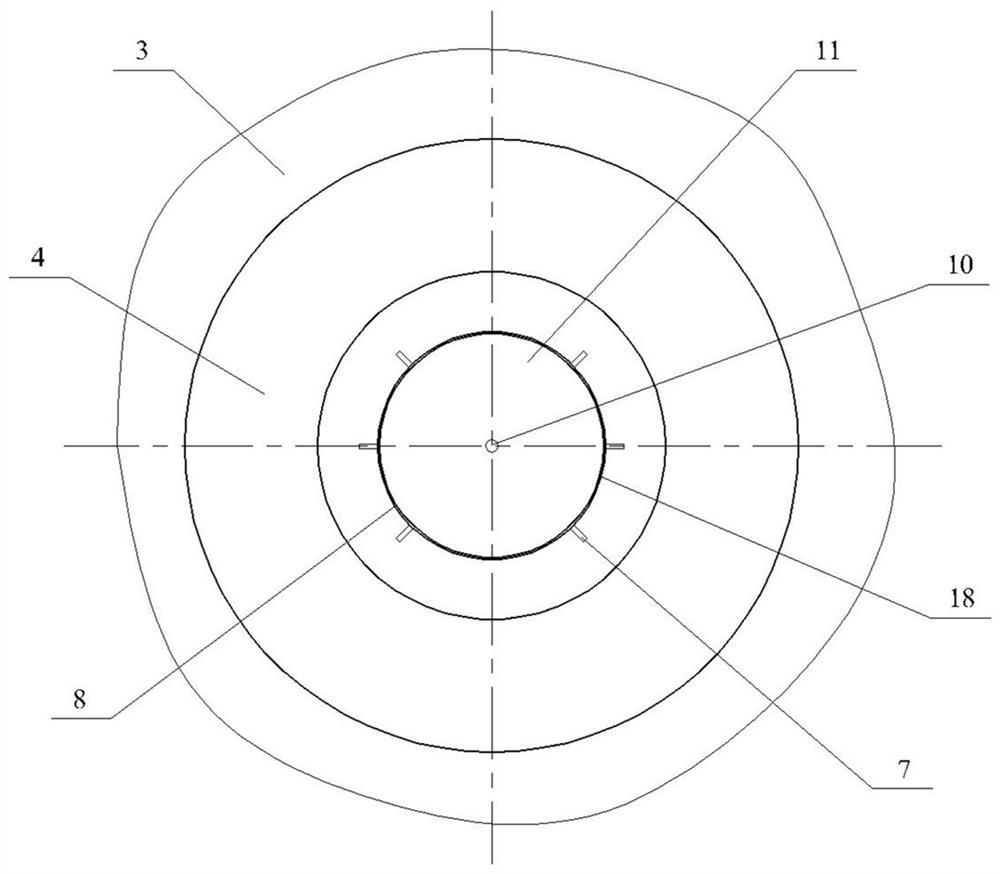

[0030] like figure 2As shown, the multifunctional water tower is mainly composed of a bottom plate 1 , a tower tube 18 , a condensation pipe 16 , an axial flow fan 6 , an air intake pipe 7 , a return pipe 12 , a gas tank 10 , a top plate 9 , and a photovoltaic panel 11 . Among them, the six blade r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com