A method for rectifying and separating carboxylic acid based on ethylene oxide hydration reaction

A technology of ethylene oxide hydration and reactive distillation, which is applied in the separation/purification of carboxylic acid compounds, carboxylate preparation, chemical instruments and methods, etc., can solve the problem of increasing the difficulty of rectification separation, consuming huge energy, and solvent Environmental pollution and other issues, to achieve the effect of improving the comprehensive economic effect, fast reaction rate, and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

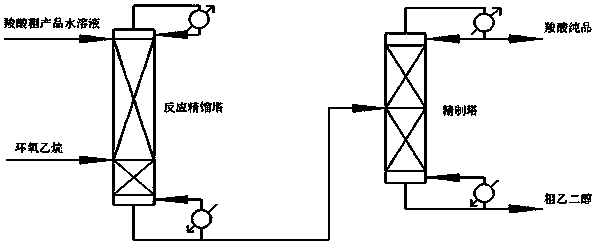

Embodiment 1

[0028] The aqueous solution of the crude product of acetic acid with a concentration of 20% is continuously fed from the upper feed port of the reaction section of the reactive distillation tower, and ethylene oxide is continuously fed from the lower feed port of the reaction section of the reactive distillation tower, and the operation of the reactive distillation tower The pressure is 1 Mpa, so that the water in the crude acetic acid aqueous solution and ethylene oxide undergo hydration reaction in the reaction section to generate ethylene glycol and a small amount of diethylene glycol and triethylene glycol. The top temperature of the reactive distillation tower is 179~181°C, the bottom temperature is 220~224°C, total reflux is carried out at the top of the tower, and carboxylic acid, ethylene glycol, diethylene glycol, triethylene glycol and a small amount of water. The production fluid from the bottom of the tower continuously enters the refining tower for further rectifi...

Embodiment 2

[0031] The butyric acid crude product aqueous solution with a concentration of 40% is continuously fed from the upper feed port of the reaction section of the reactive distillation tower, and ethylene oxide is continuously fed from the lower feed port of the reaction section of the reactive distillation tower. The operating pressure is 1 Mpa, so that the water in the crude butyric acid aqueous solution and ethylene oxide undergo hydration reaction in the reaction section to generate ethylene glycol and a small amount of diethylene glycol and triethylene glycol. The top temperature of the reactive distillation tower is 180~182°C, the bottom temperature is 200~202°C, total reflux is carried out at the top of the tower, and butyric acid, ethylene glycol, diethylene glycol, triethylene glycol and a small amount of water. The produced liquid from the bottom of the tower continuously enters the refining tower for further rectification and purification. Pure butyric acid is extracte...

Embodiment 3

[0034] The crude formic acid aqueous solution with a concentration of 60% is continuously fed from the upper feed port of the reaction section of the reactive distillation tower, and ethylene oxide is continuously fed from the lower feed port of the reaction section of the reactive distillation tower, and the reaction distillation tower operates The pressure is 1 Mpa, so that the water in the crude formic acid aqueous solution and ethylene oxide undergo hydration reaction in the reaction section to generate ethylene glycol and a small amount of diethylene glycol and triethylene glycol. The temperature at the top of the reactive distillation tower is 185~186°C, the temperature at the bottom of the tower is 196~198°C, total reflux is carried out at the top of the tower, and formic acid, ethylene glycol, diethylene glycol, triethylene glycol and a small amount of formic acid are continuously extracted from the bottom of the tower of water. The production liquid from the bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com