Method for rapidly preparing periodic corrugation structure on basis of premodulation laser

A periodic and corrugated technology, applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of complex preparation process, limited application, expensive equipment, etc., and achieve the effect of simple process, low preparation cost and elimination of heat conduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

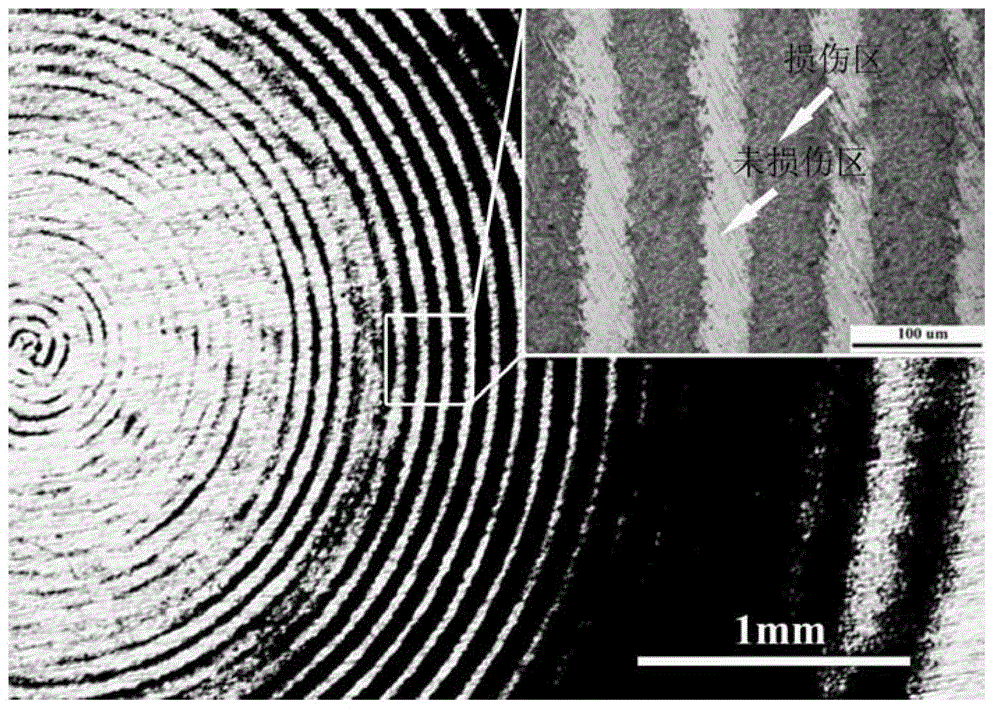

Embodiment 1

[0028] 1) Divide 10×10×4mm 3 The pure magnesium material was polished step by step with No. 400-2000 water sandpaper in turn, cleaned with anhydrous ethanol ultrasonically, and then fixed on the three-dimensional mobile platform in the air environment, and the distance between the mobile platform and the laser was fixed, and the distance was 20cm.

[0029] 2) Install the prefabricated mirror on the head of the laser, and use the prefabricated mirror to premodulate the laser beam.

[0030] 3) Move the above-mentioned metal material in a direction perpendicular to the incident laser beam, and adjust its position on the platform by observing the change in the position of the light spot incident on the surface of the above-mentioned metal material in the imaging system, so that the light spot is perpendicular to the entire surface of the above-mentioned metal material , and make the light spots all fall on the surface of the above metal material. The parameters of the laser are:...

Embodiment 2

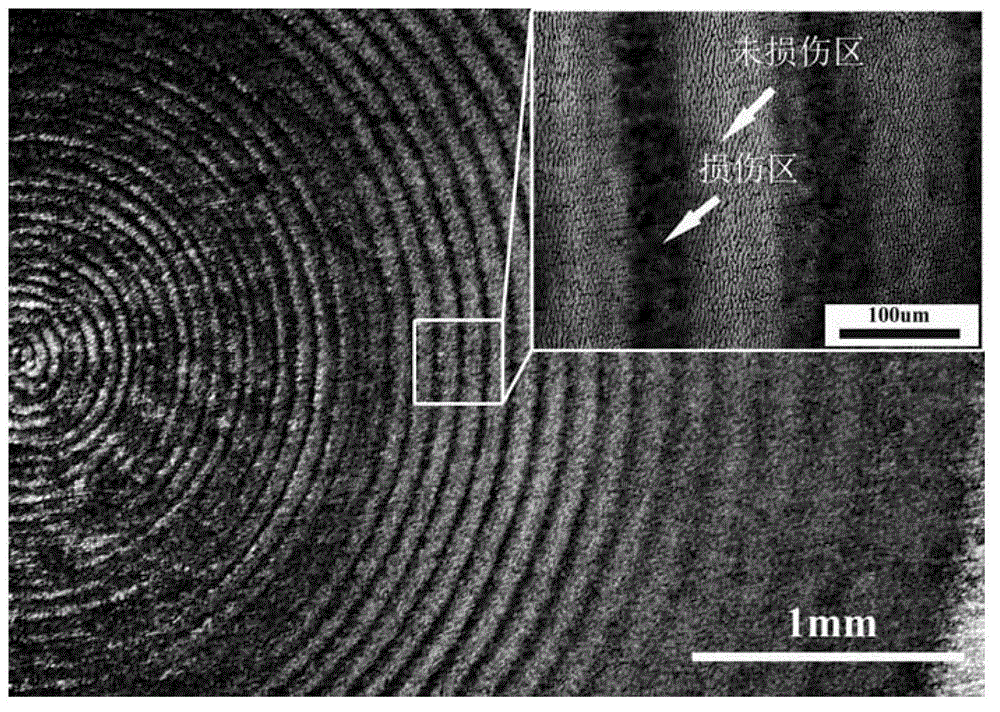

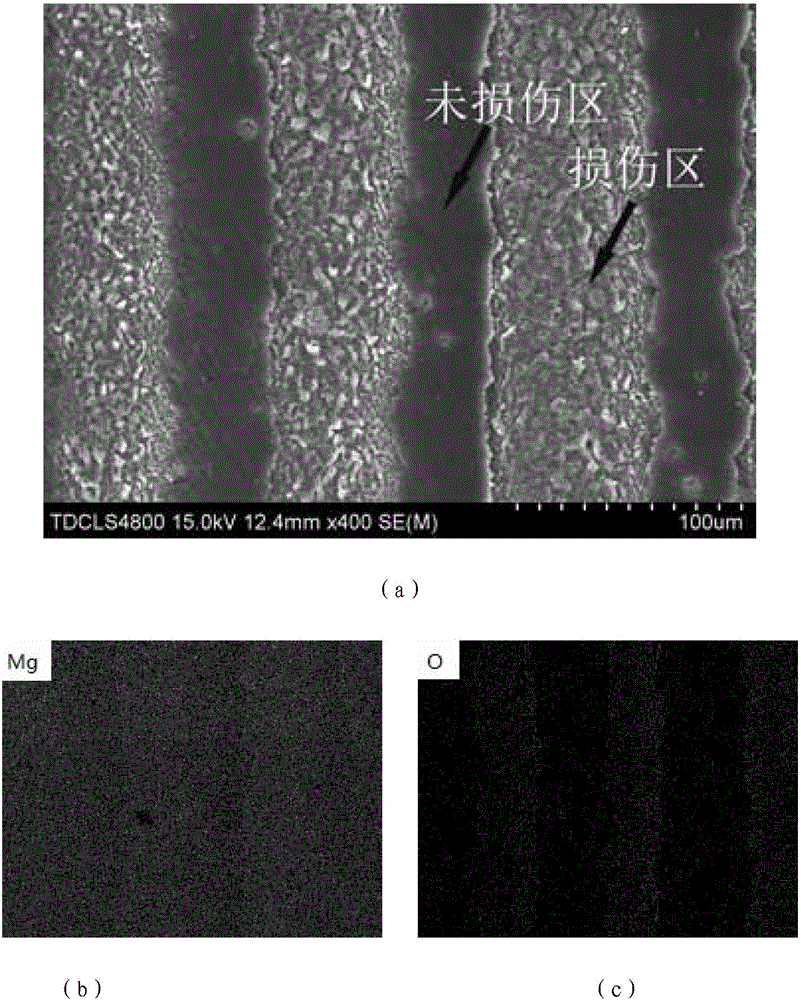

[0036] The material is pure titanium, the number of laser bombardments is 200, and other technical steps and process conditions are the same as in Example 1. In this case, it was observed that the surface of pure titanium after pulsed laser irradiation has a structure similar to that of Example 1, such as figure 2 shown.

[0037] The above-mentioned pure magnesium sample with a micron-scale periodic ring structure is placed on a three-dimensional stereo microscope, and the ring structure and depth of the sample surface are tested.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com