Anoxic-aerobic vertical flow artificial wetland system

A constructed wetland system, vertical flow wetland technology, applied in aerobic and anaerobic process treatment, chemical instruments and methods, water/sludge/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

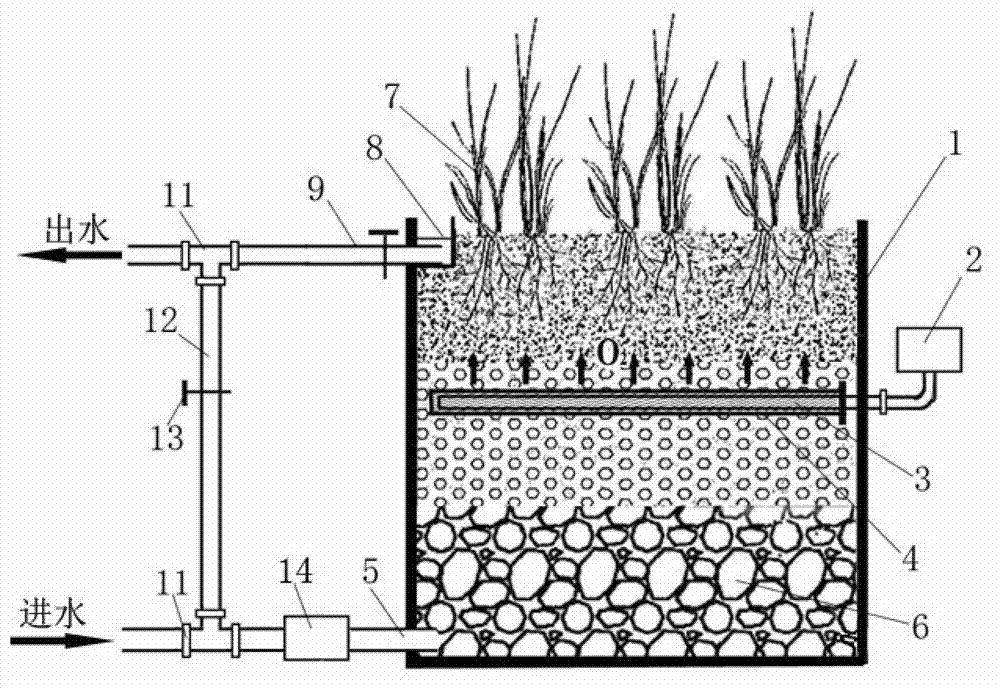

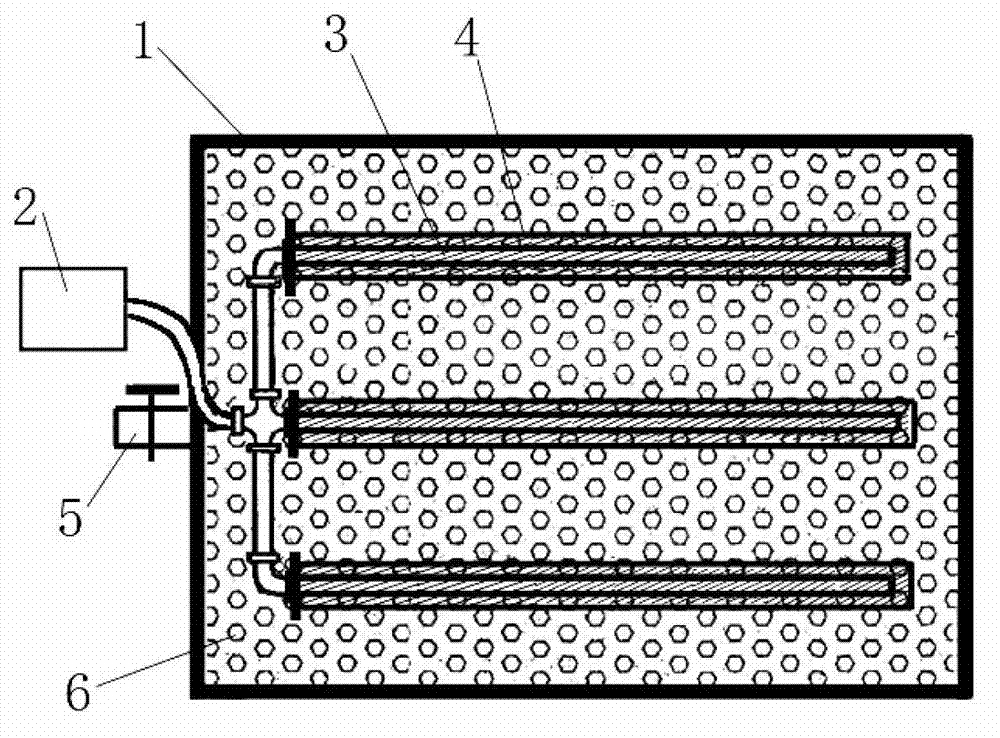

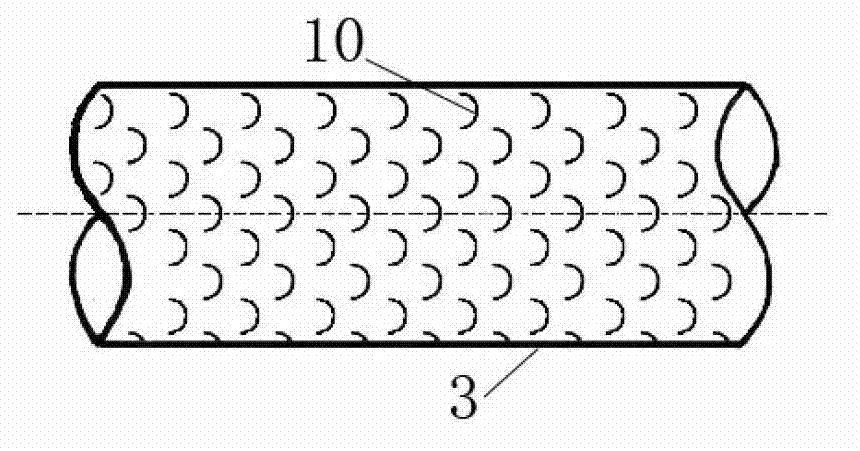

[0015] Such as figure 1 and figure 2 As shown, the anoxic-aerobic vertical flow wetland of the present invention mainly includes a wetland pool body 1, an aeration device, a water inlet pipe 5, a drain pipe 9, an outlet water return device and wetland plants 7. The four sides and the bottom of the wetland pool body 1 are treated with anti-seepage. The lower part of the wetland pool body 1 is provided with a water inlet pipe 5, and the upper part is provided with an outlet weir 8 and a drain pipe 9, and a water outlet return device composed of a tee 11, a return pipe 12, and a return valve 13 is arranged behind the drain pipe 9; the wetland pool The matrix filler 6 needs to be laid in the body 1, the particle size of the matrix filler 6 gradually decreases from bottom to top, coarse sand is laid on the top layer, the aeration device is located at 2 / 3 of the water level of the pool body, and the aeration tube 3 is covered with a protective Rigid plastic network pipe 4, the gr...

Embodiment 2

[0019] Such as Figure 4 As shown, this embodiment adopts the downstream operation mode to treat sewage. The water inlet pipe 5 is arranged at the upper part of the wetland pool body 1, the drain pipe 9 is arranged at the bottom, and the rest of the structure is basically the same as that of the first embodiment.

[0020] During operation, the sewage enters the vertical flow wetland system through the water inlet pipe 5, first enters the upper aerobic zone for nitrification reaction, then flows into the anoxic zone at the bottom of the pool body for denitrification reaction, and finally the purified sewage is discharged from the bottom drain pipe 9 Drain the pool.

Embodiment 3

[0022] Such as Figure 5 As shown, the aeration device in the present invention can also adopt an annular aeration tube, which is suitable for circular wetlands and the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com