Sewage in-situ purification system using drainage ditch

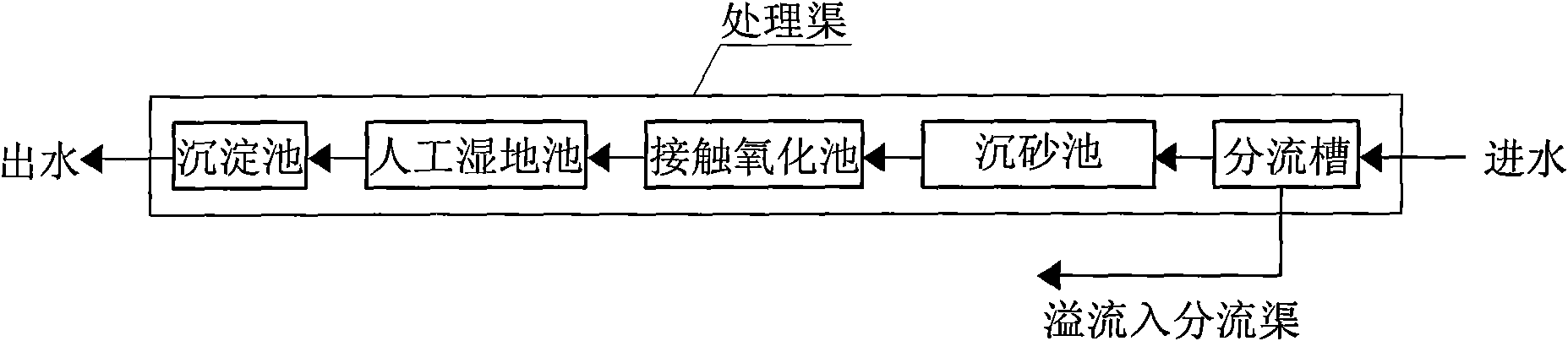

A technology of purification system and drainage ditch, which is applied in the direction of water/sewage multi-stage treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of not fully utilizing the drainage ditch space and short contact time, etc. Achieve good adaptability and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

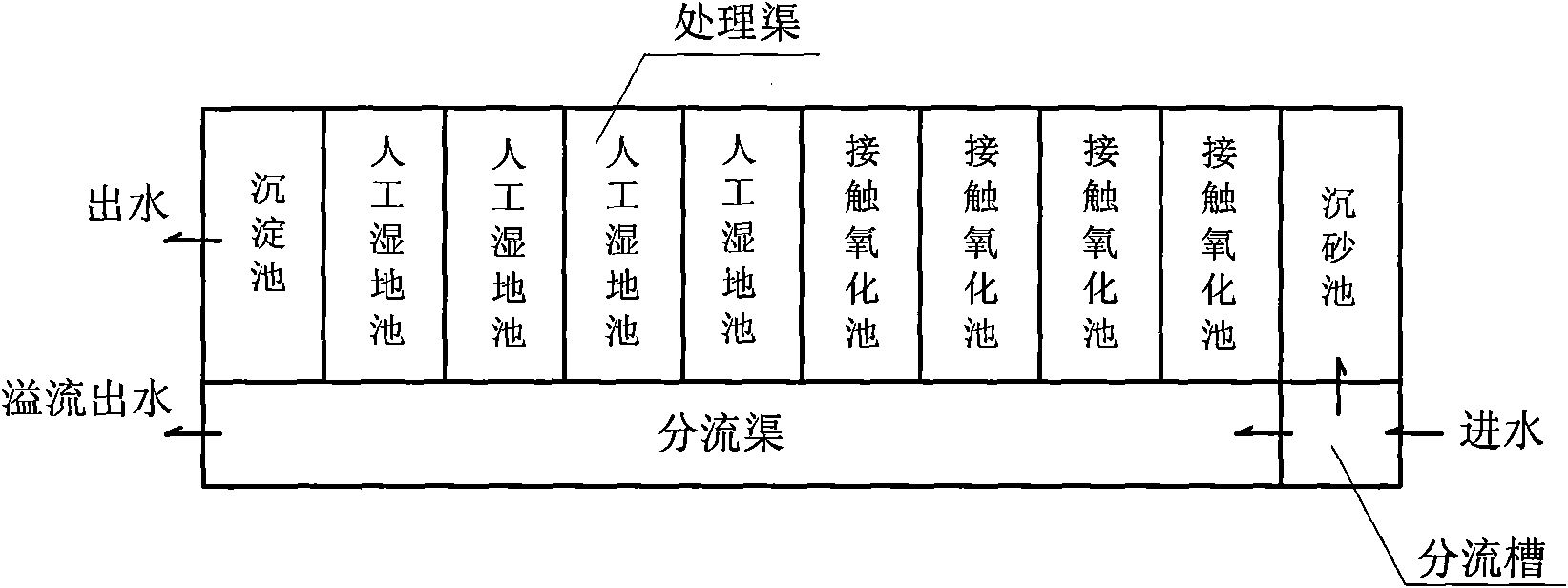

[0038] A stone-built sewage discharge channel in a small town. The source of sewage is the mixed sewage of domestic sewage and fecal water from residents on both sides of the street in the small town. The sewage is discharged into a stone-built underground channel. into the Yangtze River.

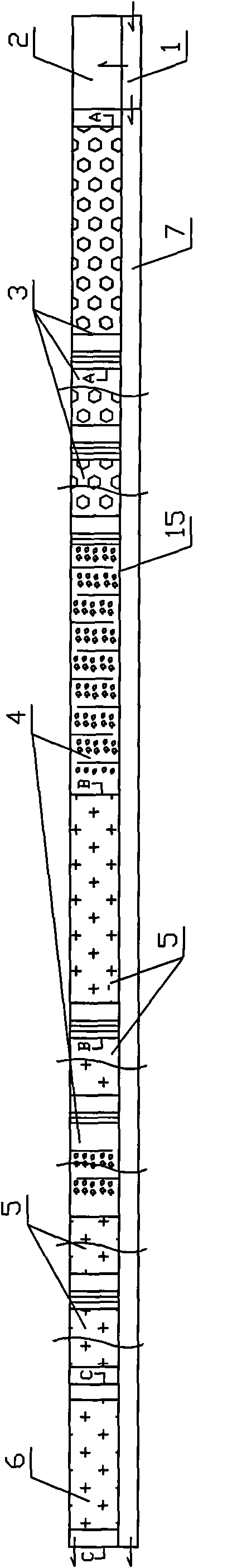

[0039] Total channel width: W 1 =1.2m; treatment channel width: W 2 =0.7m; Partition wall thickness: W 3 =0.2m; Diverter width: W 2 = 0.3m; channel height: H = 1.0m; treatment channel length: L = 46.0m;

[0040] Diverter length × width × depth = 2.0m × 0.3m × (0.1~0.3)m;

[0041] The length of the grid grit chamber × width × depth = 2.0m × 0.3m × 0.2m, the water inlet is equipped with 1 bamboo grid with an aperture of 0.01m × 0.01m, and the water outlet is equipped with 3 bamboo grids with an aperture of 0.01m×0.01m, 0.008m×0.008m, 0.005m×0.005m;

[0042] There are 3 sections in the vertical flow contact oxidation section, the length of each section x width x depth = 4.0m x 0.7m x 0.1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com