Etching device

A technology for etching device and etching solution, which is applied to spray devices, spray devices, and devices for coating liquid on surfaces, etc., can solve problems such as uneven flow rate of etching solution, uneven etching of curved glass, and inconsistent residence time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

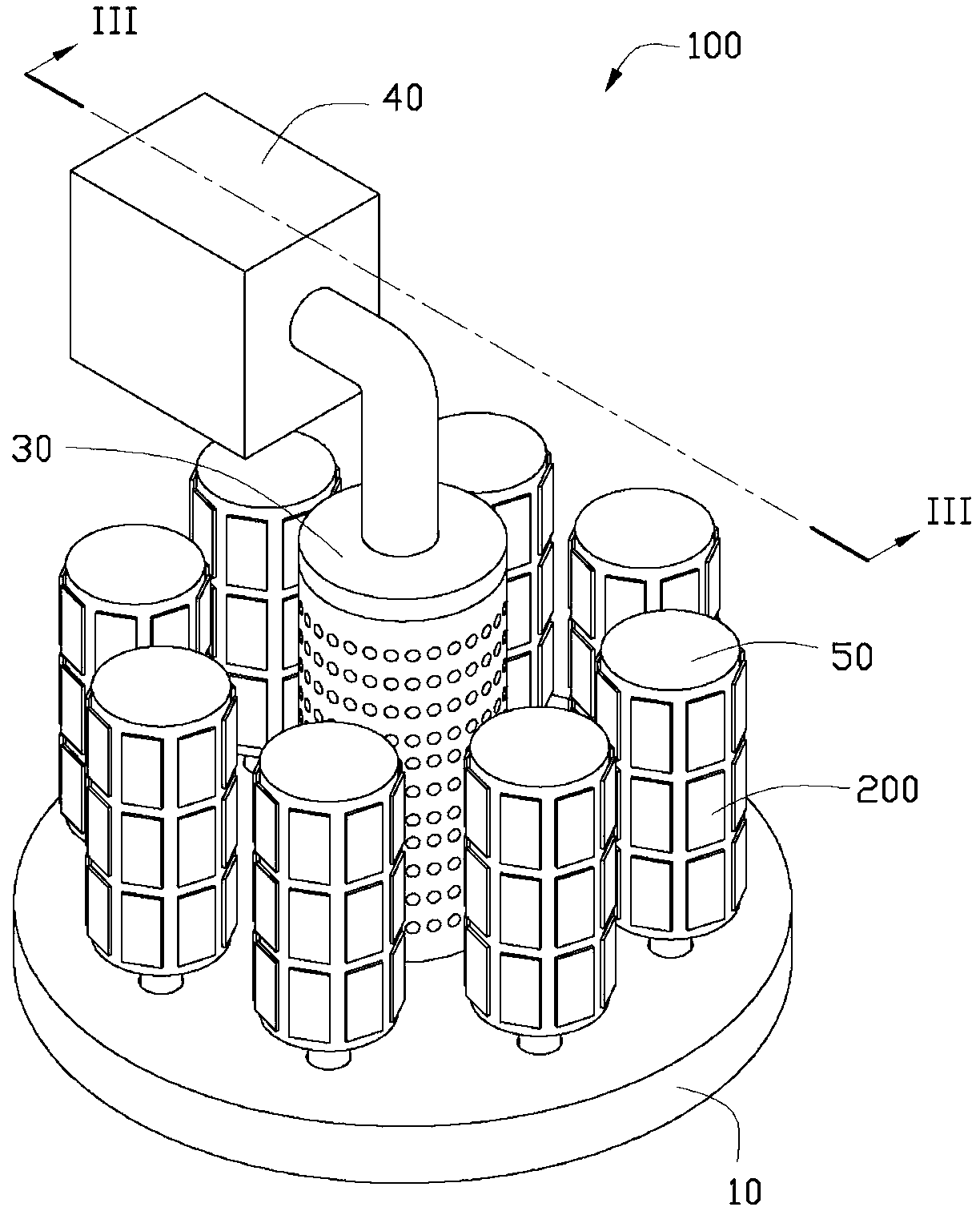

[0012] see figure 1 , the etching device 100 is used to etch the surface of the curved glass 200 , the etching device 100 includes a substrate 10 , a liquid storage part 30 , an air compressor 40 and a rotating part 50 . The liquid storage part 30 is used for containing the etching liquid, and it is connected with the air compressor 40 to spray the etching liquid from the liquid storage part 30 . The rotating member 50 is rotatably mounted on the base 10 and adjacent to the liquid storage member 30 . The curved glass 200 is fixedly installed on the rotating part 50 , and the etching solution sprayed from the liquid storage part 30 can be sprayed onto the surface of the curved glass 200 to etch the curved glass 200 .

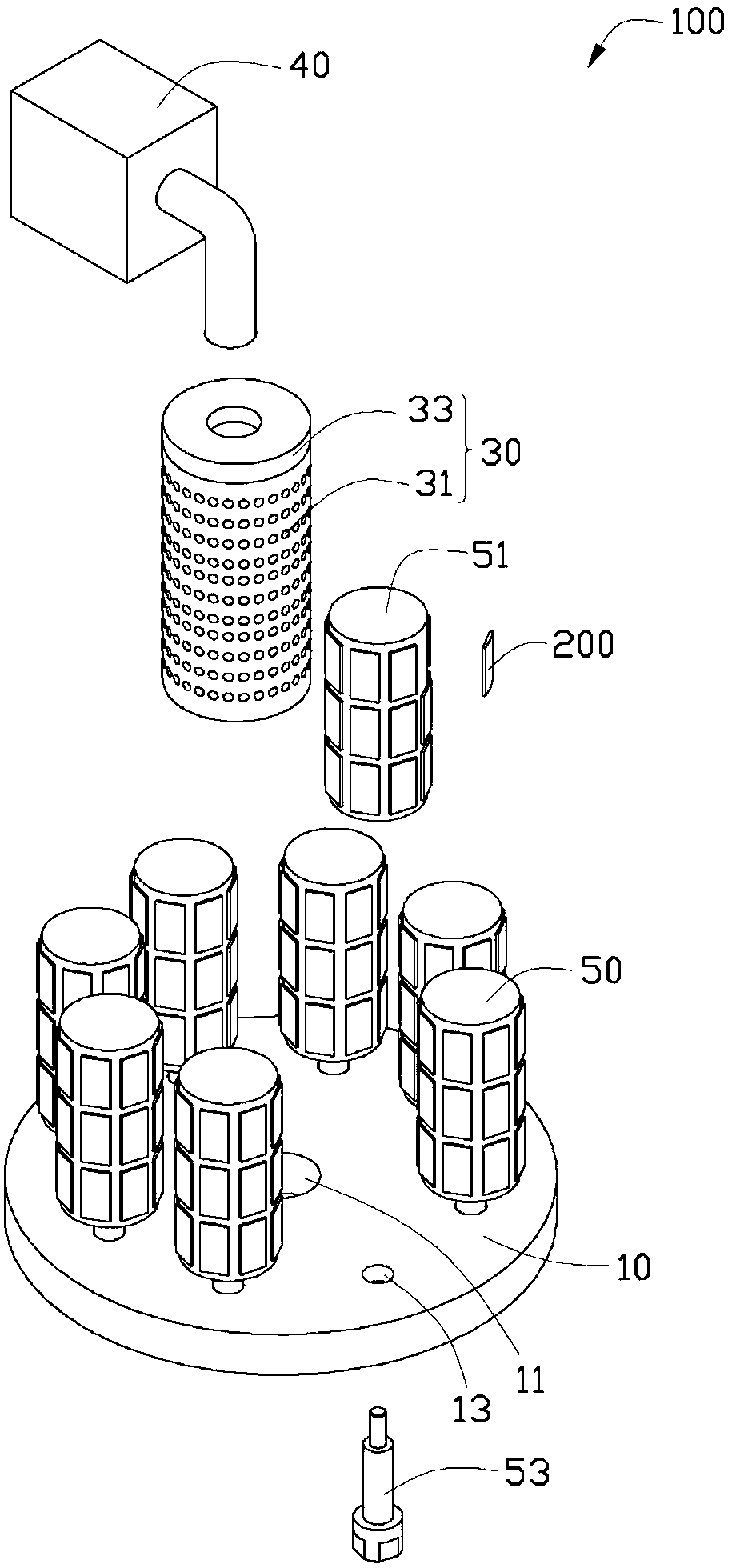

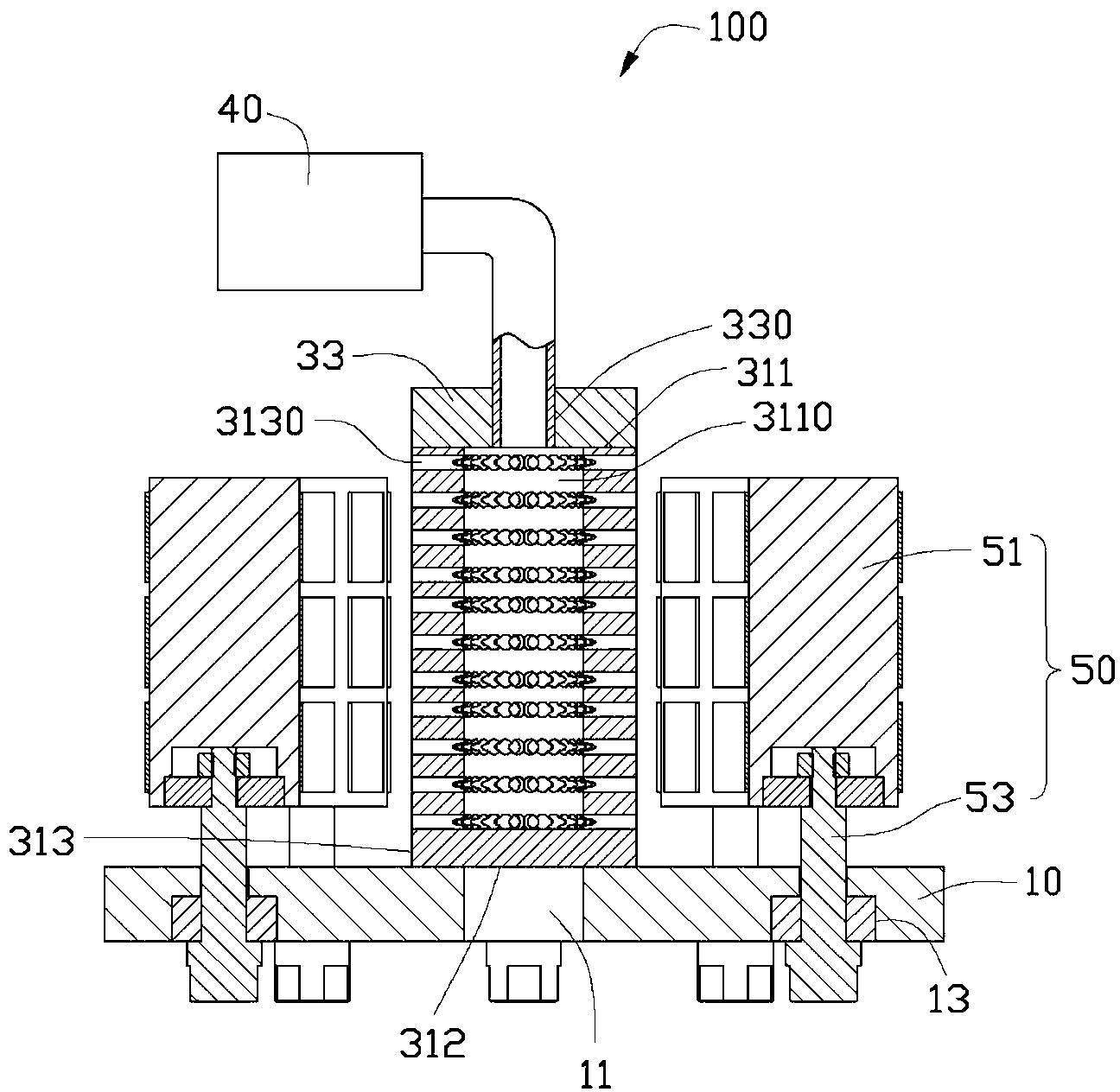

[0013] Please also see figure 2 and image 3 , the base body 10 is used to install the liquid storage part 30 and the rotating part 50, and in the embodiment of the present invention, the base body 10 is disc-shaped. The base body 10 defines a first installa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com