Novel underground spray coating material and preparation method thereof

A technology of spraying materials and mine workers, which is applied in the field of concrete materials and mine support concrete, which can solve the problems of difficulty in slurry transportation, high cost, and high dust intensity on the construction site, and achieve improved sprayability and bonding performance Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with embodiment the present invention is further described.

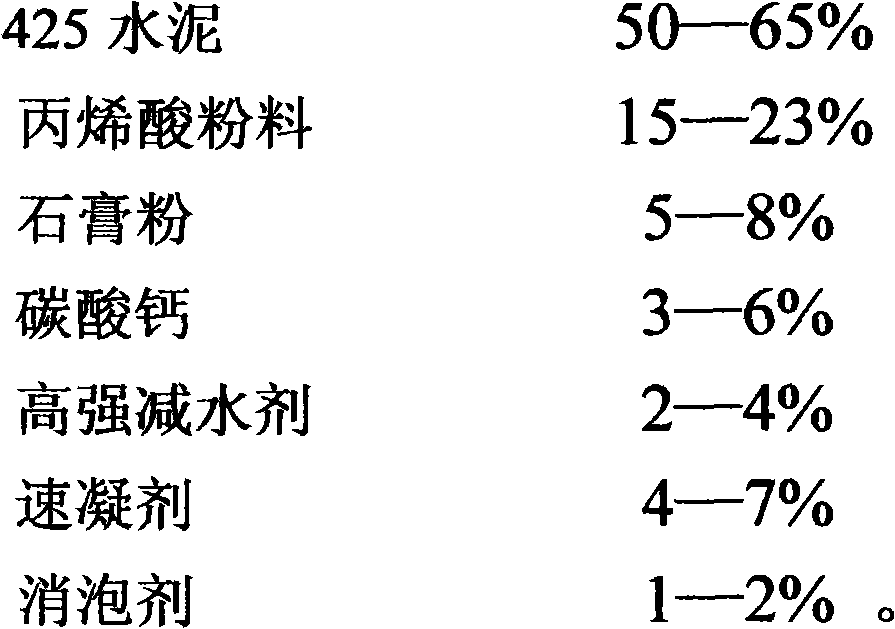

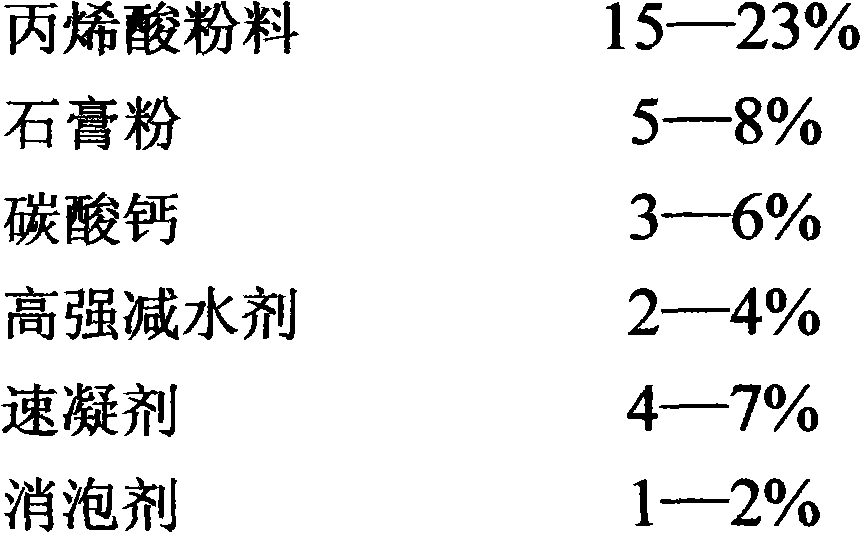

[0015] The polymer cement-based slurry is composed of additives, cement and water; the ratio of additives + cement to water is 1:1; the additives are composed of the following components by weight:

[0016]

[0017] A novel underground spraying material and a preparation method thereof, comprising the following steps:

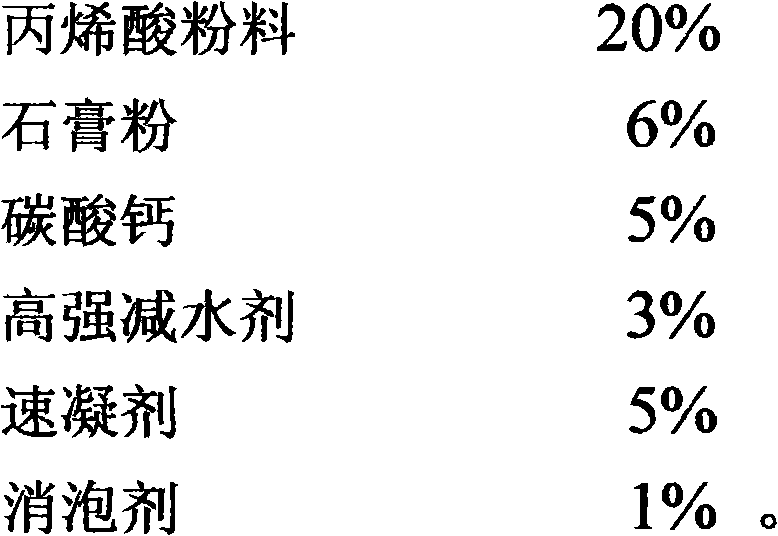

[0018] A. After the total weight of the prepared polymer cement-based slurry is determined, the water content is obtained according to 50% of the total weight, and the weight of 425 cement is calculated according to 50-65% of the water content, mixed with water, and then according to the proportion of water volume Add additives:

[0019]

[0020] B. Stir with a pneumatic mixing tank, first stir the cement slurry, then add additives, the mixing time is based on the slurry being stirred evenly and completely suspended;

[0021] C. The finished cement slurry that has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com