Method for preparing bentazone aqueous agent

A technology of bentazone water agent and water phase, which is applied in botany equipment and methods, herbicides, algicides, biocides, etc., and can solve the problems of high cost, high environmental protection pressure, dark color of bentazone water agent, etc. problems, to achieve the effects of low production cost, reduced sewage discharge, and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

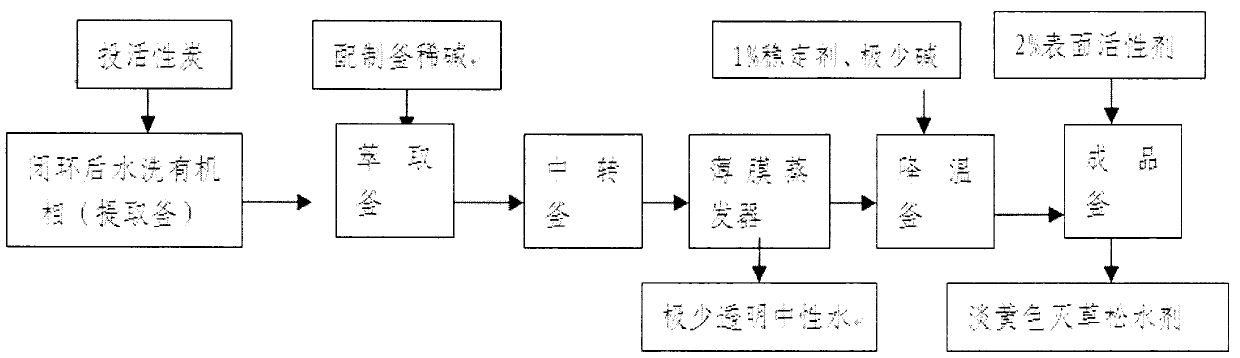

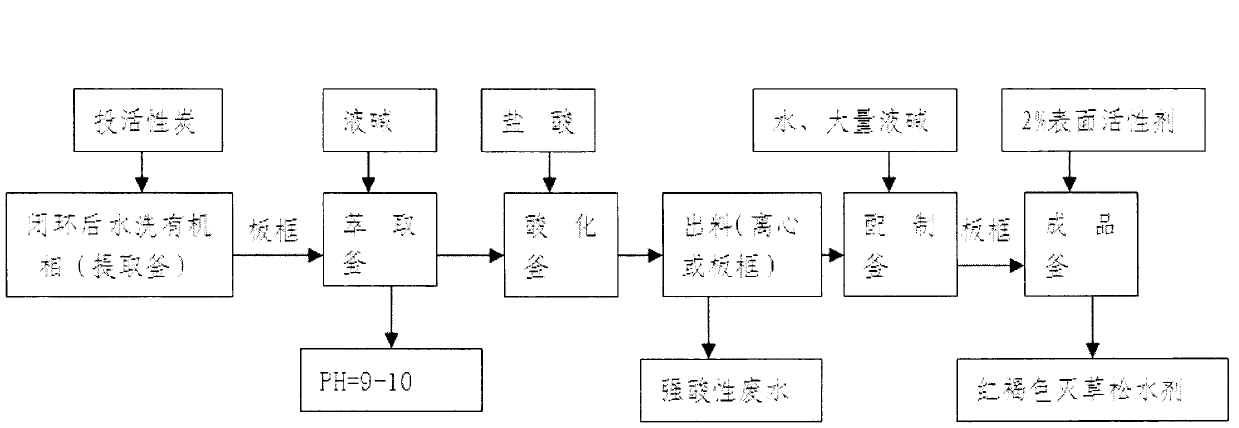

Image

Examples

Embodiment Construction

[0019] A kind of preparation method of bentazone water agent, described this method, the first step, after the organic phase is washed with water after adopting closed-loop synthesis, cast activated carbon, stir at constant temperature for 30 minutes and filter to the extraction kettle through plate and frame; Wash the plate frame with tap water to the extraction kettle, and finish washing; blow dry for 30 minutes, and remove the activated carbon;

[0020] The second step, dilute alkali preparation: prepare 32% ionic membrane liquid alkali to the preparation kettle, add tap water to prepare the alkali content to 5% to 31%, and prepare it for extraction;

[0021] The third step, extraction kettle: Slowly add the pre-prepared dilute alkali dropwise, the dropping temperature is controlled at 25-60°C, and the pH value of the material is adjusted to 3-11;

[0022] The fourth step, after the pH value of the material is adjusted, let it stand for 2 hours, take the upper layer of wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com