Dust-suppression and rock-discharge system utilizing tailing slurry and dust-suppression and rock-discharge method

A technology for mud and tailings, which is applied in chemical instruments and methods, wet separation, earthwork drilling, etc. The effect of eliminating potential safety hazards and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

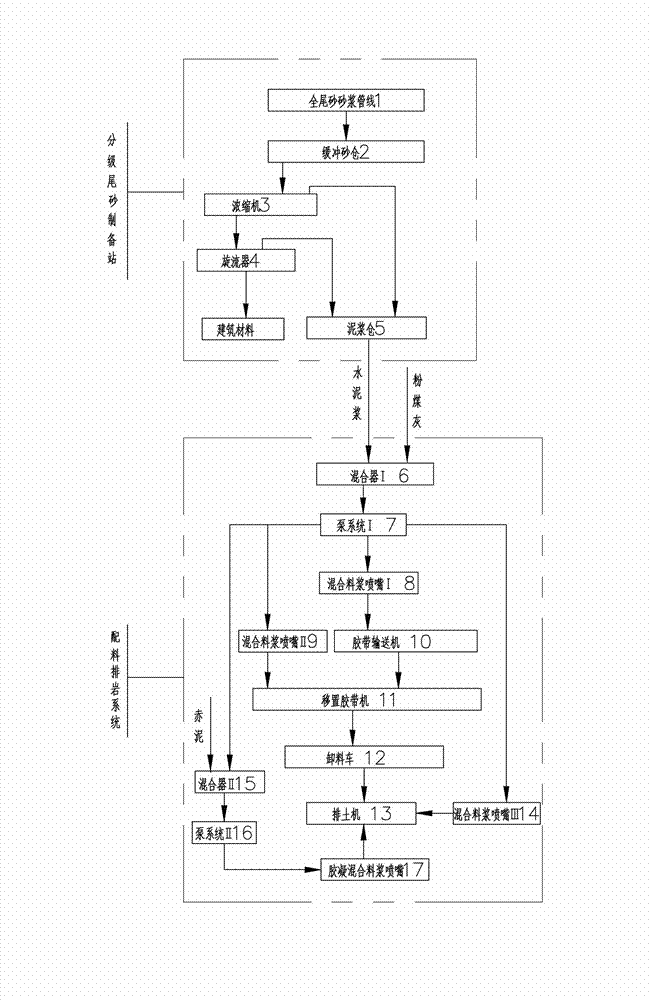

[0025] Such as figure 1 As shown, a dust suppression and rock discharge system using tailings mud of the present invention is characterized in that it includes a graded tailings preparation station and a batching rock discharge system,

[0026] The graded tailings preparation station consists of a full tailings mortar pipeline 1, a buffer sand bin 2 connected to the full tailings mortar pipeline 1, a thickener 3 connected to the buffer sand bin 2, and a thickener 3 The connected cyclone 4 is composed of the mud bin 5 connected with the thickener 3 and the cyclone 4 respectively;

[0027] The batching and rock removal system includes two mixers, two pump systems, four nozzles, a belt conveyor, a displacement belt conveyor, an unloading truck and a soil dumper, and the mixer I6 is in phase with the pump system I7. connection, the pump system I7 is also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com