Roller drill bit lubrication device

A technology of roller cone drilling rigs and lubricating devices, which is applied in the direction of engine lubrication, drill bits, lubricating parts, etc. It can solve the problems that the structure of the bit lubricating device is not simple and compact, increases maintenance costs, increases energy consumption, etc., and achieves a significant lubricating effect. Reduced maintenance costs and responsive action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

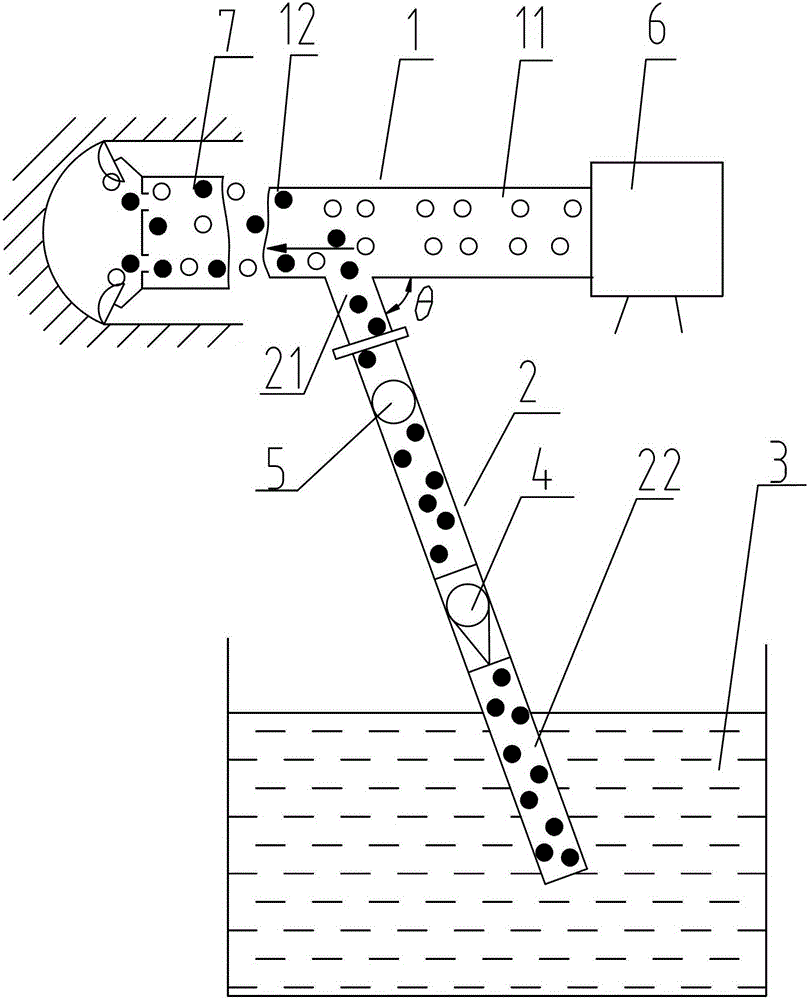

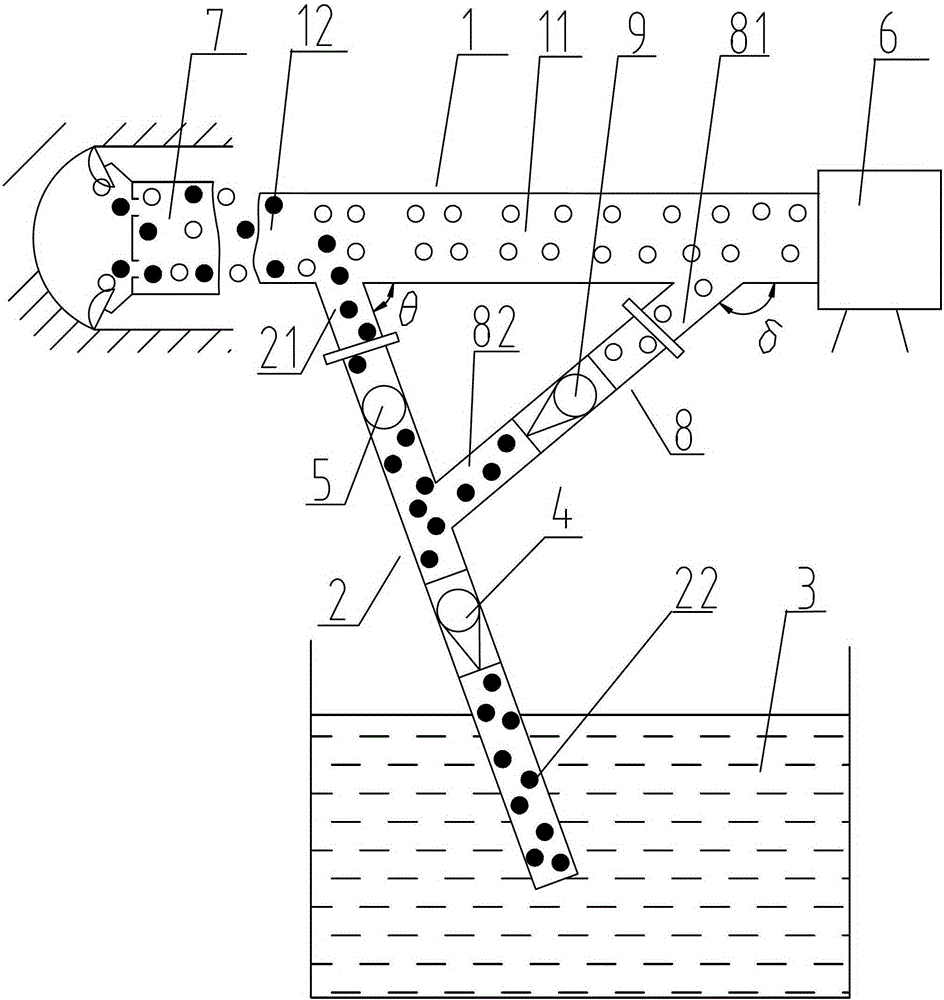

[0017] like figure 1 As shown, the bit lubricating device of the roller cone drilling rig includes a main air duct 1, one end of the main air duct 1 is connected with the main air compressor 6, and the main air compressor 6 is powered by a motor to continuously compress the air outside and transport it to In the main air duct 1, the other end of the main air duct 1 is connected with the drill pipe through related components such as the main air cover and the static ring. The thin oil is transported to the drill bit 7 through the main air pipe 1 and the through hole in the middle of the drill rod. There is a through hole on the main air duct 1, and a thin oil pipe 2 is connected in the through hole. The thin oil pipe 2 is composed of a thin oil pipe joint 21 and a thin oil pipe body 22. The thin oil pipe joint 21 is a straight pipe. It is fixed on the main air duct 1 by means of threaded connection or welding, and the included angle θ with the compressed air flow-in direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com