Afterheat recycling device and method of high temperature flue gas containing high adhesive dust

A waste heat recovery device and high-temperature flue gas technology, applied in the steam generation method using heat carrier, waste heat treatment, energy efficiency improvement, etc., can solve the problems of unusable equipment, blockage of heat exchanger, and inability of continuous operation of rotary hearth furnace, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

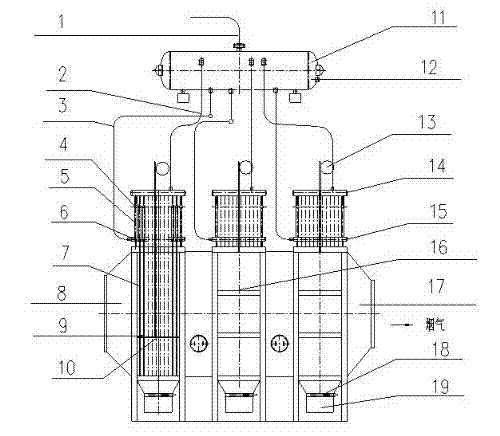

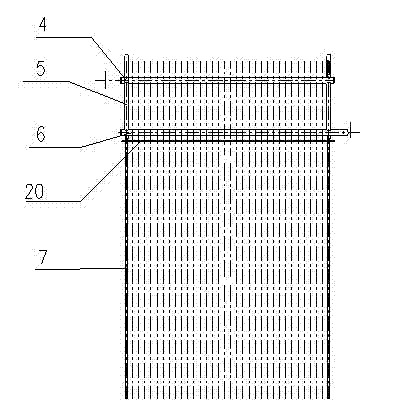

[0029] Such as figure 1 As shown, the device of the present invention comprises: a steam output pipe 1, an ascending pipe 2, a descending pipe 3, an upper connecting pipe 4, a water jacket pipe 5, a lower connecting pipe 6, a heat pipe 7, a flue gas inlet 8, a scraper 9, a scraper Plate connecting pipe 10, steam drum 11, deoxygenated water inlet pipe 12, scraper driving mechanism 13, upper header pipe 14, lower header pipe 15, flue 16, flue gas outlet 17, airtight valve 18, ash collection bin 19.

[0030] Such as figure 1 As shown, the flue 16 of the waste heat recovery device is arranged horizontally. The waste heat recovery device uses heat pipes as heat exchange elements, and the outer side of the heat pipes is a bare pipe or a straight finned tube. The heat absorption section of the heat pipe 7 is vertically inserted into the flue 16, and the lower section of the heat pipe 7 is in a free state; the heat absorption section of the heat pipe 7 Scraper 9 is arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com