Refrigeratory refrigerating system in cold chain

A refrigeration system and cold storage technology, which is applied to household refrigeration equipment, coolers, defrosting, etc., and can solve the problems of increased operating current and noise of compressors, not being the most energy-efficient, and insufficient use of compressor power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

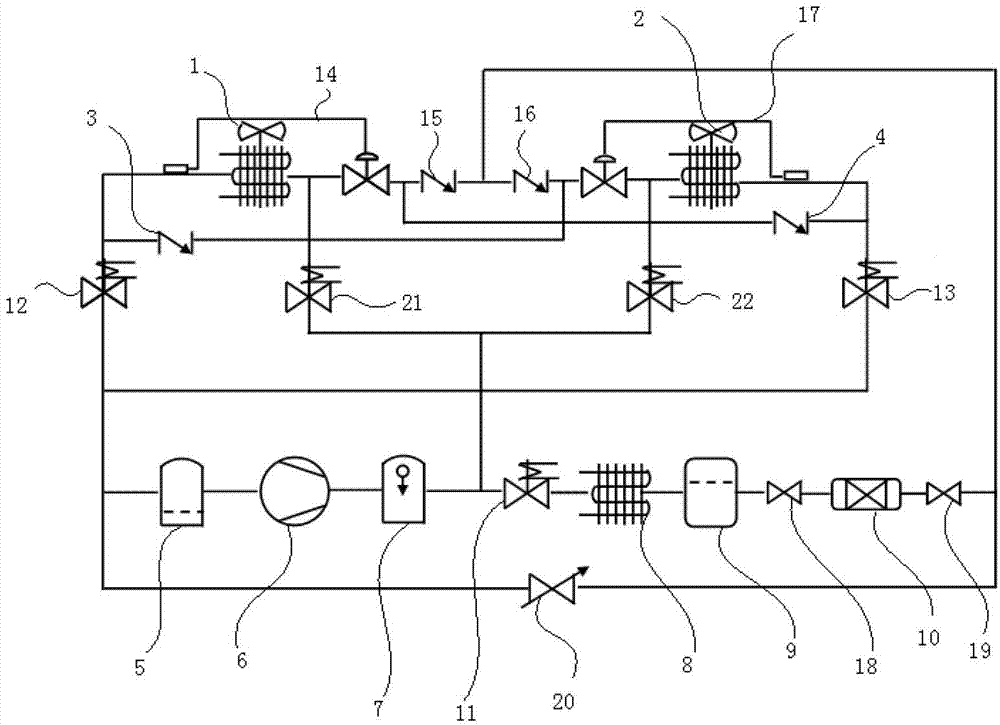

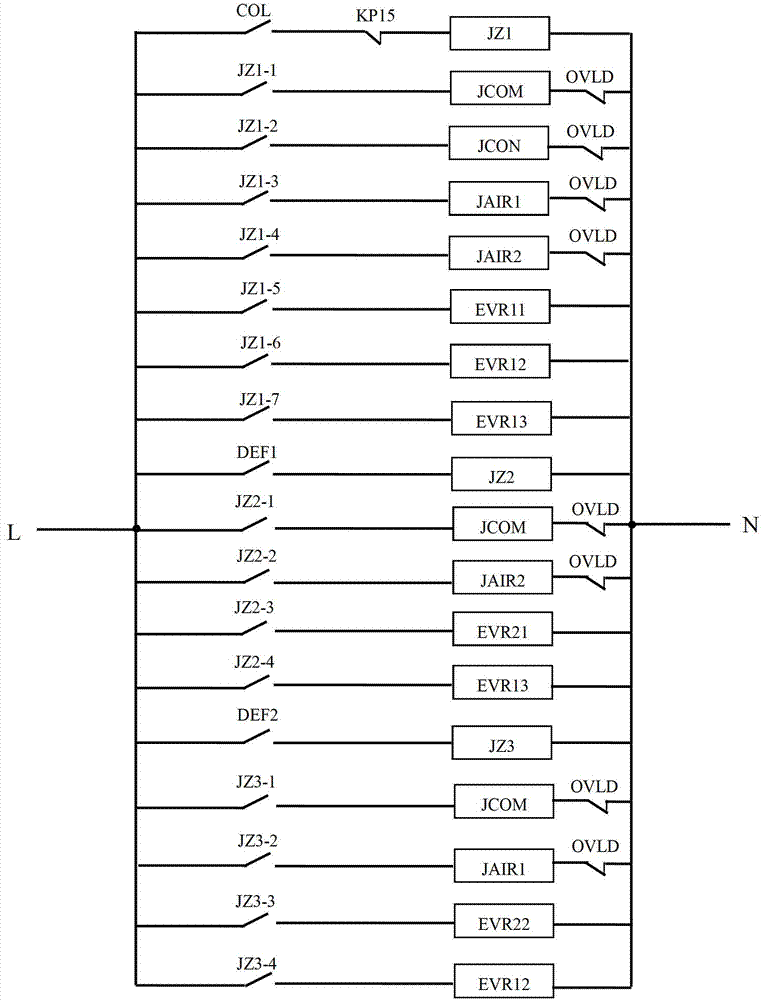

[0062] like figure 1 As shown, the refrigeration cycle system in the present invention is mainly composed of: compressor 6, oil separator 7, refrigeration solenoid valve 11, condenser 8, liquid receiver 9, first hand valve 18, filter, second hand valve 19 , the first one-way valve 15, the second one-way valve 16, the first expansion valve 14, the second expansion valve 17, the first air cooler 1, the second air cooler 2, the first return valve 12, the second Air return valve 13 and gas-liquid separator 5 are formed. When the temperature of the cold storage is higher than the set temperature, the microcomputer control system outputs the cooling signal COL, which is connected to the coil of the intermediate relay JZ1 through the pressure protector KP15, JZ1 pulls in, and its normally open contacts respectively control the compression of the compressor 6. The machine contactor, the condenser fan contactor of condenser 8, the motor contactor of air cooler 1, and the motor contact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com