Waste heat recovery device for moderate temperature flue gas containing high binding dust and method

A flue gas waste heat recovery device technology, applied in waste heat treatment, climate sustainability, energy efficiency improvement, etc., can solve the problems of unusable equipment, waste heat recovery system unable to absorb heat, blockage of heat exchangers, etc., to save fuel Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

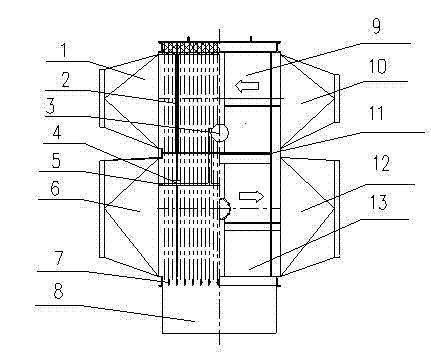

[0022] Such as figure 1 As shown, the device of the present invention includes a heat exchanger, and a horizontal gas pipeline 9 and a flue gas pipeline 13, the gas pipeline 9 is arranged above the flue gas pipeline 13, and is sealed and isolated by a partition 11; the heat exchanger consists of Several heat pipes 2 are formed. The heat pipe 2 passes through the partition 11 and is vertically arranged. The heat release section of the heat pipe 2, that is, its upper section is arranged in the gas pipeline 9, and the heat absorption section of the heat pipe 2, that is, its lower section is arranged in the flue gas pipeline 13.

[0023] Such as figure 1 As shown, a scraper 4 is provided on the outside of the heat-absorbing section of each heat pipe, and the scraper 4 is connected to the scraper connecting pipe 5; Outside the heat exchanger, it is in drive connection with the scraper driving mechanism 3 arranged outside the heat exchanger.

[0024] Such as figure 1 As shown, b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com