Method for testing dynamic indentation of material

A technology of dynamic indentation and experimental method, which is applied in the direction of testing the hardness of materials, etc., and can solve the problems of large measurement error of time history of indentation amount, affecting measurement accuracy, and indentation force with additional oscillations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

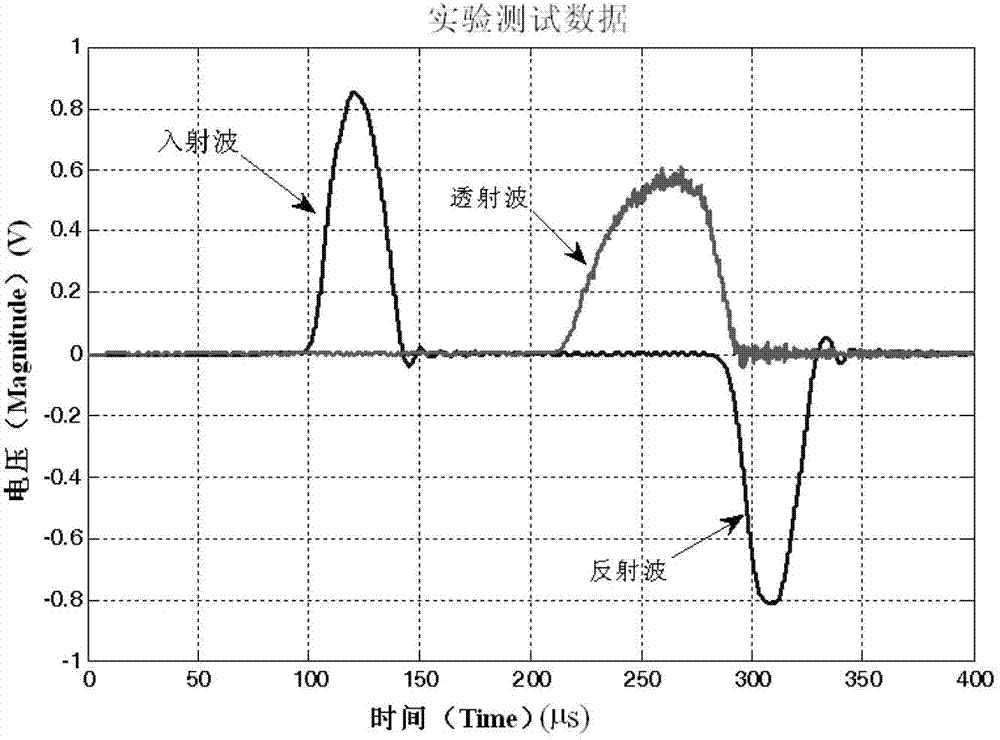

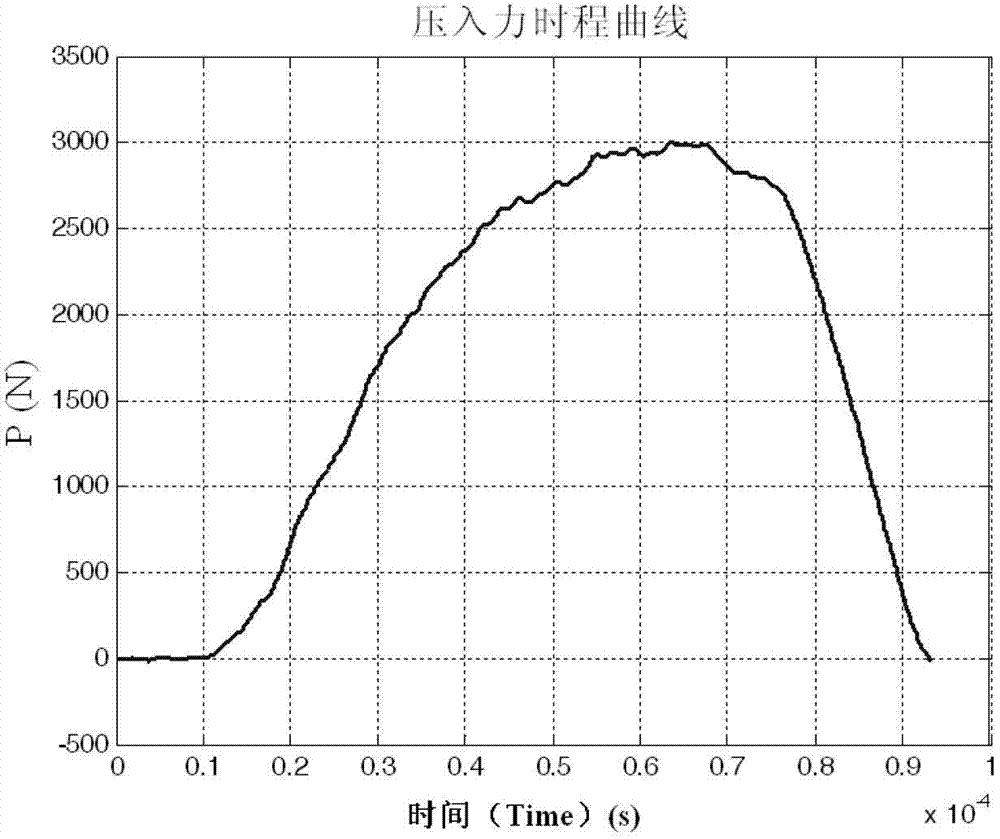

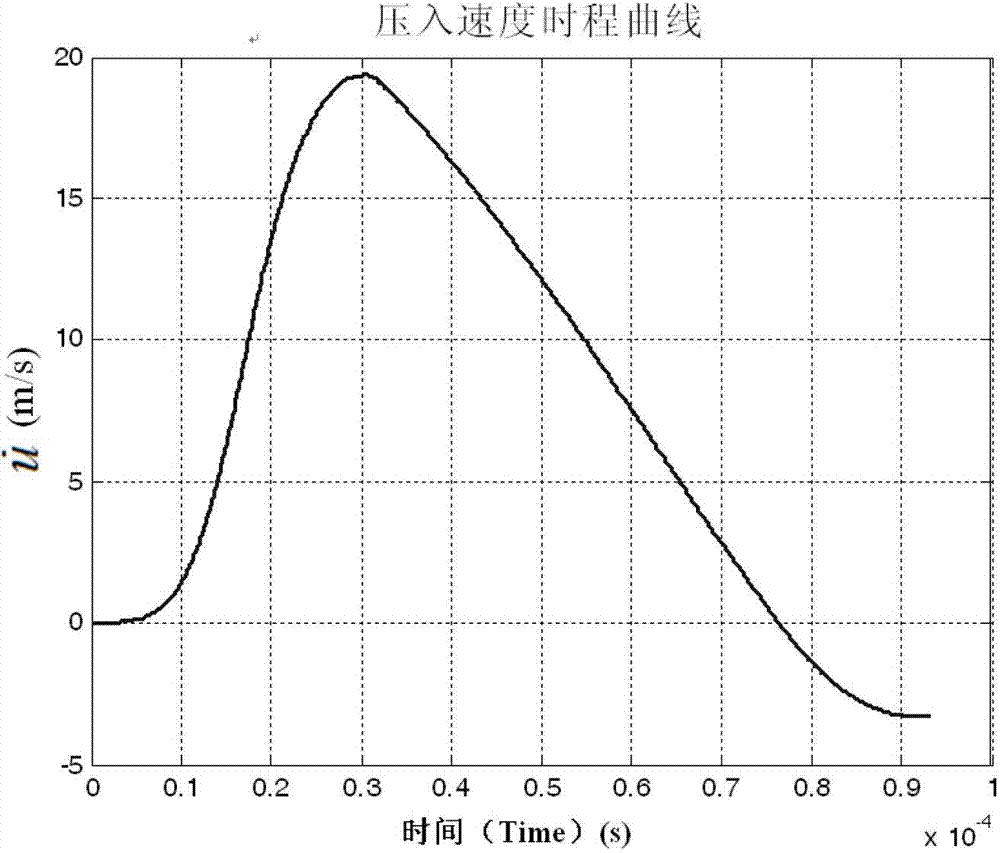

[0033] As shown in the figure, a material dynamic indentation test method includes the following specific steps:

[0034] (1) Take the incident rod 2 and the transmission rod 3 that satisfy the one-dimensional stress wave condition. The materials of the incident rod 2 and the transmission rod 3 are the same and the diameters are equal. Set up a cylindrical test piece 7 on one end face of the incident rod 2, and make the test piece 7 and the incident rod 2 or transmission rod 3 meet the wave impedance matching condition ρ s C s A s =ρ 0 C 0 A 0 , where: ρ s Indicates the density of the tested piece, C s Indicates the one-dimensional stress wave velocity of the tested piece, A s Indicates the cross-sectional area of the tested object, ρ 0 Indicates the density of incident rods or transmitted rods, C 0 Denotes the one-dimensional stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com