Device and method for realizing model reference adaptive control on operation speed of combine harvester

A combine harvester, reference self-adaptive technology, applied in self-adaptive control, general control system, control/adjustment system, etc., can solve the problems of high driver operation level and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

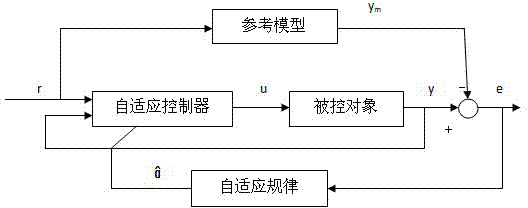

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

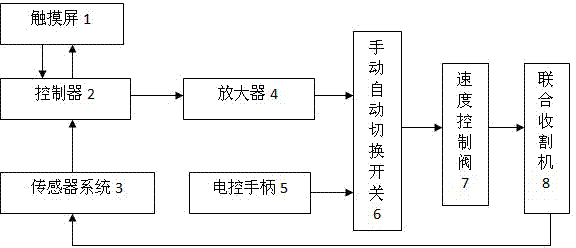

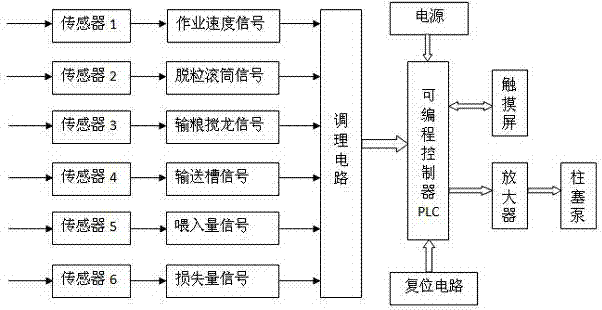

[0020] Such as figure 1 and figure 2 As shown, the hardware system of the combine harvester operation speed model reference adaptive control device is composed of a controller 2, a touch screen 1, a sensor system 3, a manual / automatic switch 6, and an execution system, wherein the execution system includes an electric control handle 5, a speed Control valve 7 and amplifier 4.

[0021] The sensor system 3 is composed of sensors installed at various monitoring points on the combine harvester 8, including a Hall speed sensor installed on the threshing drum, the grain transport auger and the shaft of the forward wheel, and installed on the shaft of the header auger. The feeding amount sensor on the upper part and the loss amount sensor installed at the tail of the combine harvester 8 sieve. The output of the sensor system 3 is connected to the input of the controller 2 .

[0022] The touch screen 1 is connected to the output end of the controller 2 for displaying the operatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com