Transparent conducting film with anisotropic conductivity

A transparent conductive film, anisotropic technology, applied to the details of the conductive pattern layout, the conductive layer on the insulating carrier, the printed circuit, etc., can solve the problem of only large light transmittance, and achieve the effect of increased light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

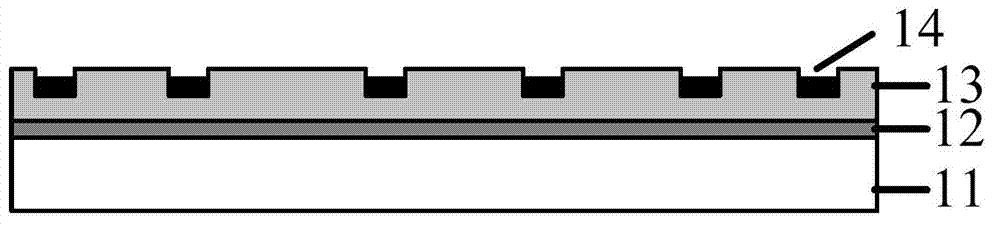

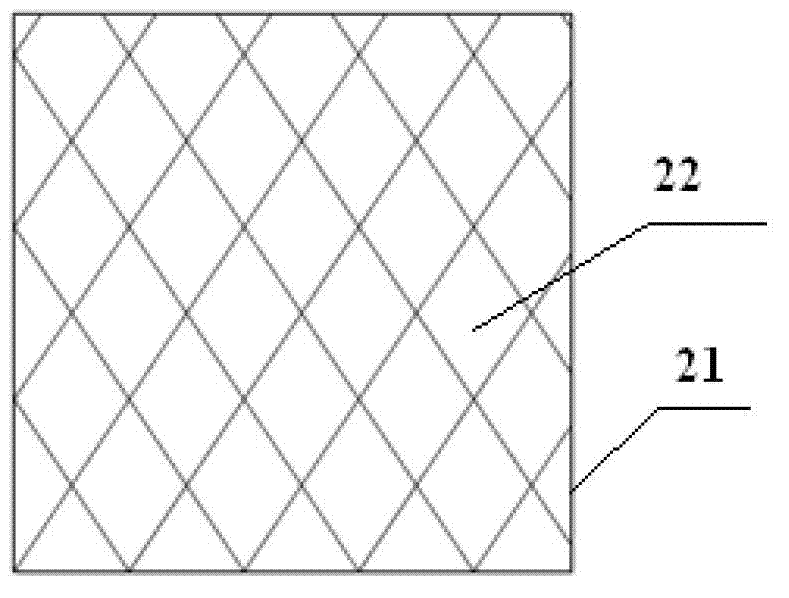

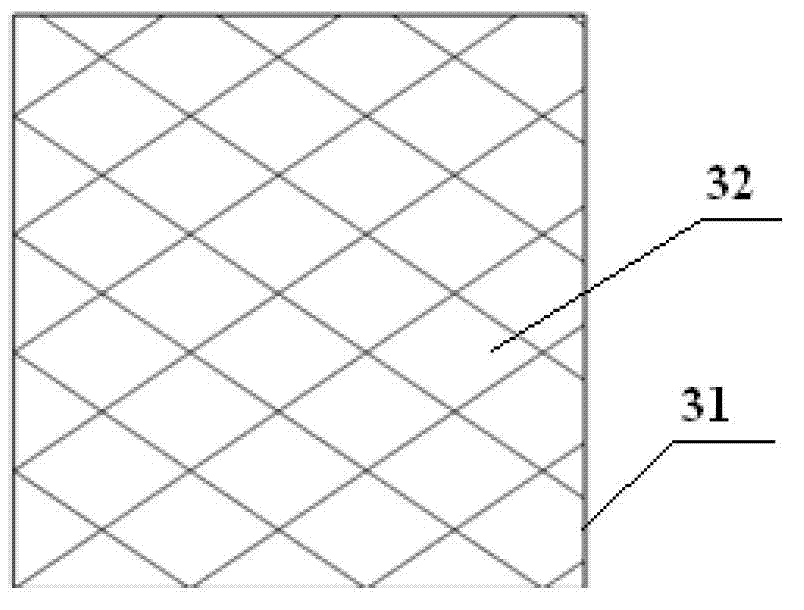

[0031] Please combine figure 1 see Figure 3A-3B , Figure 3A-3B It is a schematic diagram of the transparent conductive film module under the first embodiment of the present invention. The transparent conductive film module includes a first transparent conductive film 41 and a second transparent conductive film 51, both of the first transparent conductive film 41 and the second transparent conductive film 51 are metal-embedded transparent conductive films, combined with figure 1 As shown, the transparent conductive film is the base PET 11 from bottom to top, with a thickness of 188 μm; the acrylic UV glue 13 with a groove structure grid pattern, the groove depth is 3 μm, and the width is 2.2 μm; It is metallic silver 14, the thickness is less than the groove depth, about 2 μm, and the grooves are filled with nano-silver ink and sintered using scrape coating technology. The solid content of silver ink is 35%, and the sintering temperature is 150°C. A layer of adhesion-prom...

Embodiment 2

[0037] See Figures 6A-6B , Figures 6A-6B It is a schematic diagram of the transparent conductive film module of the second embodiment of the present invention, such as Figures 6A-6B As shown, the grid 92 of the transparent conductive film 91 is a polygonal random grid composed of metal wires, wherein the distribution probability density of the metal wire slope of the grid along the transverse direction is greater than the distribution probability density along the vertical direction, that is, the slope is close to the X-axis direction The number of metal lines is greater than the metal line whose slope is close to the Y axis; the visible light transmittance of the transparent conductive film 91 is greater than 88.6%; the grid 102 of the transparent conductive film 101 is also a polygonal random grid composed of metal lines, wherein the grid metal lines The distribution probability density of the slope along the longitudinal direction is greater than that along the transver...

Embodiment 3

[0040] Figure 8 , Figure 9 It is a schematic diagram of a transparent conductive film module according to the third embodiment of the present invention. As shown in the figure, in this embodiment, the grid pattern adopts a rectangular grid pattern composed of metal wires. Such as Figure 8 As shown, the surface grid shape of the conductive film 141 is a rectangular grid 142 , and the distribution densities of the metal wires of the rectangular grid 142 along the X and Y axes are different. The conductivity of the conductive film 141 in the X-axis direction is better than that in the Y-axis direction. The slope of most of the metal lines in the grid 142 is distributed at (-1,1). When there are more metal lines distributed in this slope range, the X The better the conductivity in the axial direction. The distribution range of the slope of most grid metal lines in the conductive film 151 is (1,+∞) and (-∞,-1) (not shown in the figure), and the conductivity in the Y-axis dir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com