Two-end synchronous driving grinding method and headstock and tailstock special for grinder

A synchronous drive, grinding machine head technology, applied in the direction of grinding frame, grinding bed, grinding machine parts, etc., can solve the problems of workpiece bending deformation, unsuitable clamping force, low processing efficiency, etc., to eliminate Bending deformation, eliminating workpiece bending, good processing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

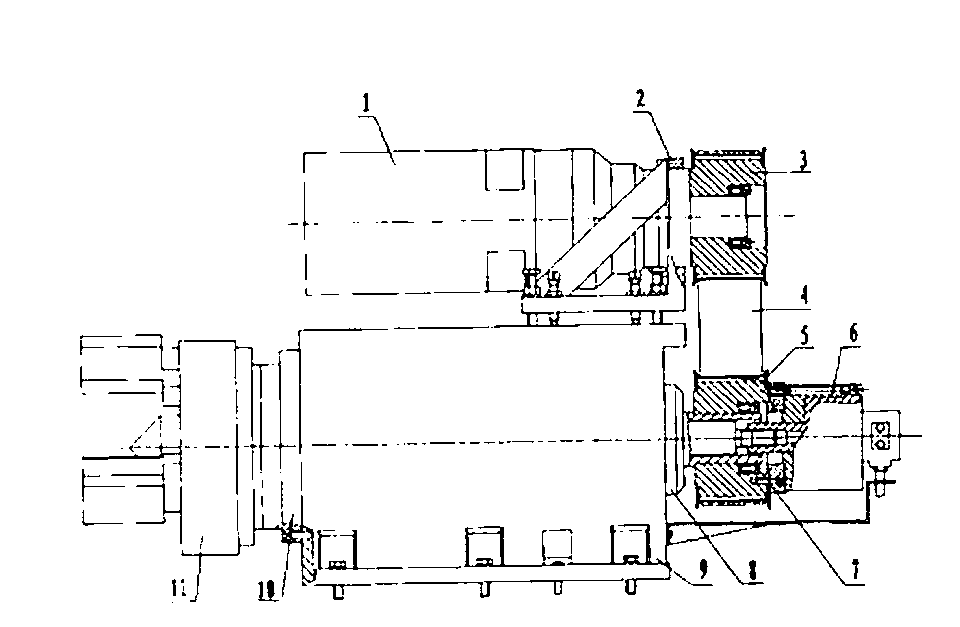

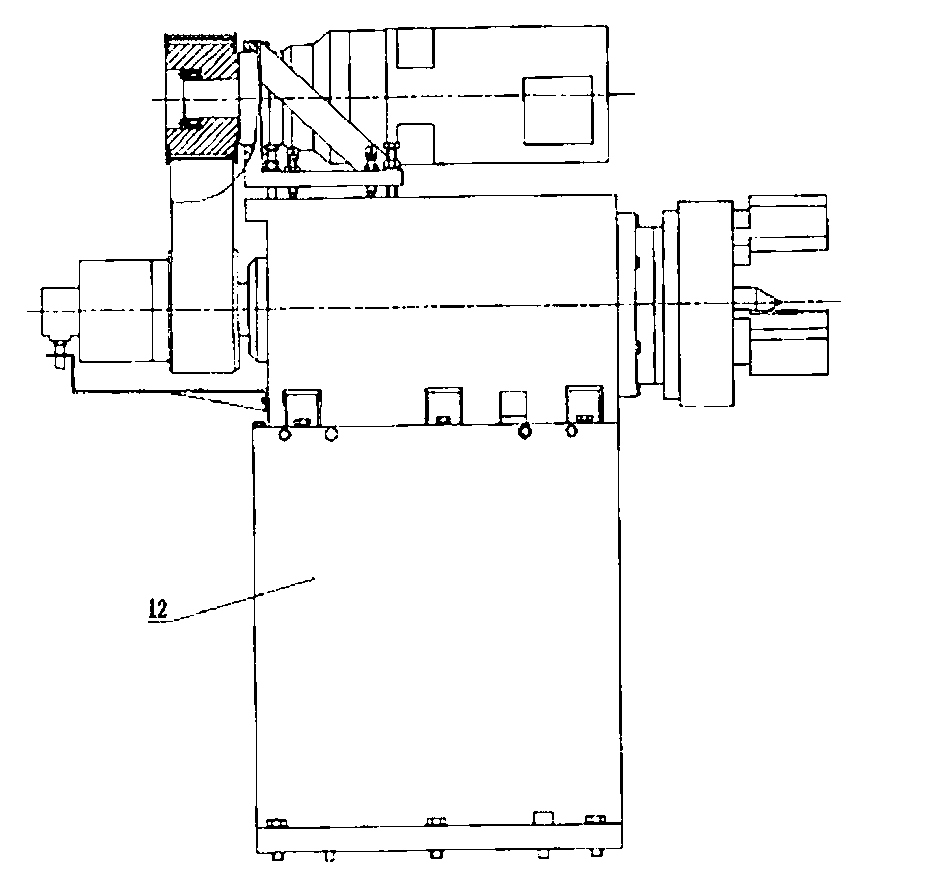

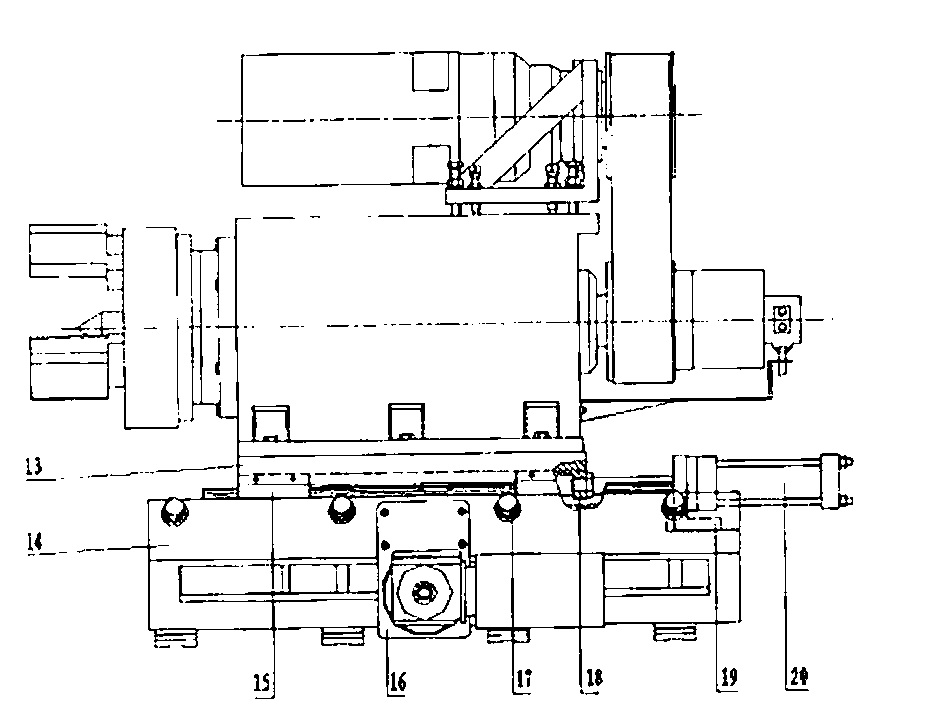

[0009] combine figure 1 , figure 2 , image 3 The details and working conditions of the present invention are described in detail. The headstock and tailstock of the grinding machine are equipped with the same set of spindle drive mechanism, and a reliable CNC control system is adopted. The spindle drive mechanism is equipped with a servo motor 1, and the end of the motor base 2 under the servo motor 1 is equipped with a synchronous pulley 3. One end of the main shaft case 9 is also equipped with a synchronous pulley 5, the synchronous belt 4 is installed between the synchronous pulley 2 and the synchronous pulley 5, the main shaft unit 10 is housed in the middle of the main shaft case 9, and the chuck 11 is installed on the main shaft unit 10 , an encoder 8 is installed on the main shaft unit 10, and an oil cylinder 6 is fixed through a flange 7 at one end of the synchronous pulley 5. The servo motor 1 drives the synchronous pulley 3 to rotate, and is transmitted to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com