Beer fresh-keeping barrel and manufacturing method

A beer preservation and production method technology, which is applied to thermal insulation containers, household refrigeration devices, lighting and heating equipment, etc., can solve the problems of low durability of all-plastic fresh-keeping barrels, poor appearance of stainless steel fresh-keeping barrels, etc., and achieves beautiful appearance and convenient cleaning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

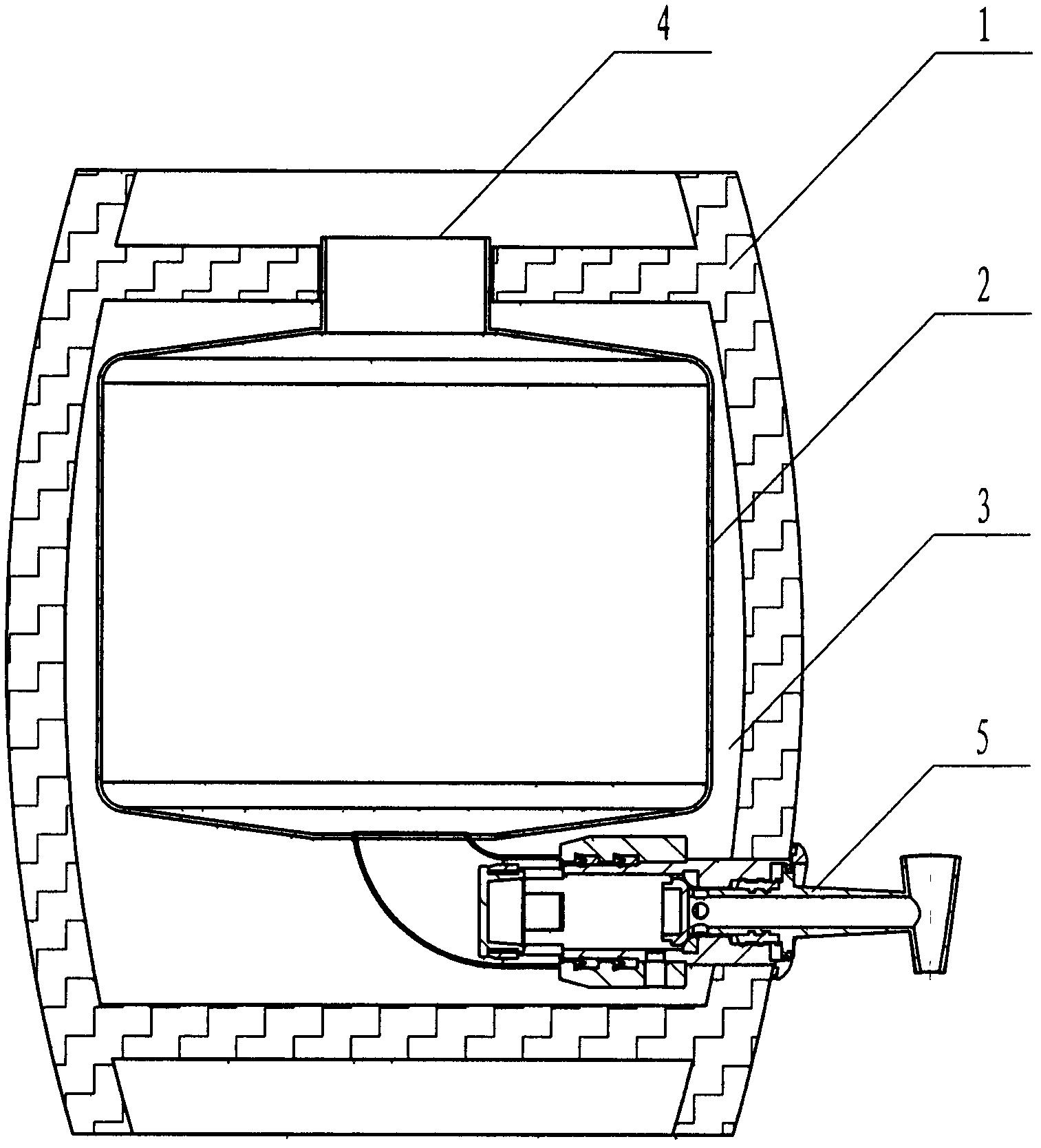

[0016] Attached below figure 1 A kind of beer fresh-keeping barrel of the present invention and its manufacturing method are described in detail below.

[0017] as attached figure 1 As shown, a kind of beer fresh-keeping bucket of the present invention, its structure comprises shell 1, plastic or stainless steel liner 2 and the insulating layer 3 that fills between shell 1 and liner 2, and shell 1 is made of oak, birch, peach, pine Made of high-quality wood such as oak, oak, etc., there is a wine pouring port 4 that runs through the outer shell 1, the insulation layer 3, and the plastic or stainless steel liner 2 on the top of the barrel body. The wine outlet valve 5 that the bottom of 2 communicates.

[0018] The shell 1 of the above-mentioned beer preservation barrel is drum-shaped.

[0019] The production method is as follows: After installing the inner tank, install wooden boards one by one, tie them tightly with iron hoops, and finally fill the middle with foaming agen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com