Fiber

A technology of fiber and fiber tow, which is applied in the field of fibers with zigzag cross-section, which can solve the problems of poor moisture absorption and moisture conduction performance, poor gloss, etc., and achieve the effect of bright luster, full color and good dyeing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

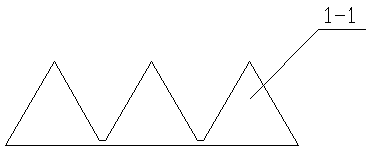

[0033] As a specific embodiment 1 of the present invention, the present invention provides a kind of fiber, and described fiber is the tow that is made up of 24 monofilaments 1, and the number of monofilaments 1 of the present invention should not be too much, preferably between 24~96, with 36 is the best, and the manufacturer can choose according to the actual situation. The cross section of the monofilament is as follows figure 1 As shown, there are three triangular sections 1-1, and the triangular sections 1-1 are regular triangular sections. The triangular section 1-1 of the present invention can be a regular triangular section or a triangular section with the same concave shape on three sides or a triangular section with the same three sides. The convex triangular section can be selected by the manufacturer according to the needs of the product. The 1-1 aspect ratio of the triangular section is 3, and the 1-1 aspect ratio of the triangular section of the present invention ...

specific Embodiment 2

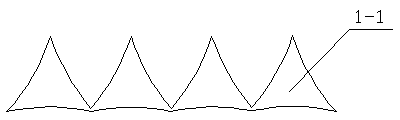

[0035] As a specific embodiment 2 of the present invention, the present invention provides a kind of fiber, and described fiber is the tow that is made up of 48 monofilaments 1, and the number of monofilaments 1 of the present invention should not be too much, preferably between 24~96, with 36 is the best, and the manufacturer can choose according to the actual situation. The cross section of the monofilament is as follows figure 2 Shown includes 4 triangular sections 1-1, each monofilament section in the fiber tow is the same, each monofilament section triangular section 1-1 of the fiber tow has the same size, each fiber tow in the present invention The monofilament section, the triangular section 1-1 of each monofilament section of the fiber tow can be the same or different. The effect of different shapes is better, but the cost is also higher. The manufacturer needs to comprehensively consider according to actual needs. The triangular section 1-1 1 is a triangular section ...

specific Embodiment 3

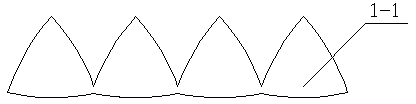

[0037] As a specific embodiment 3 of the present invention, the present invention provides a kind of fiber, and described fiber is the tow that is made up of 60 monofilaments 1, and the number of monofilaments 1 of the present invention should not be too much, preferably between 24~96, with 36 is the best, and the manufacturer can choose according to the actual situation. The cross section of the monofilament is as follows image 3 Shown includes 4 triangular sections 1-1, each monofilament section in the fiber tow is the same, each monofilament section triangular section 1-1 of the fiber tow has the same size, each fiber tow in the present invention The monofilament section, the triangular section 1-1 of each monofilament section of the fiber tow can be the same or different. The effect of different shapes is better, but the cost is also higher. The manufacturer needs to comprehensively consider according to actual needs. The triangular section 1-1 1 is a triangular section w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com