Horizontally-rotating type coal sample rapid dehumidifying device with dynamic moisture detection function

A horizontal rotary and dynamic detection technology, which is applied in the preparation of test samples and weighing by removing certain components, can solve the problems of large space occupation, long time, low efficiency, etc., and achieve the purpose of improving dehumidification efficiency, The effect of reducing overhead

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below with reference to the drawings and specific embodiments of the specification.

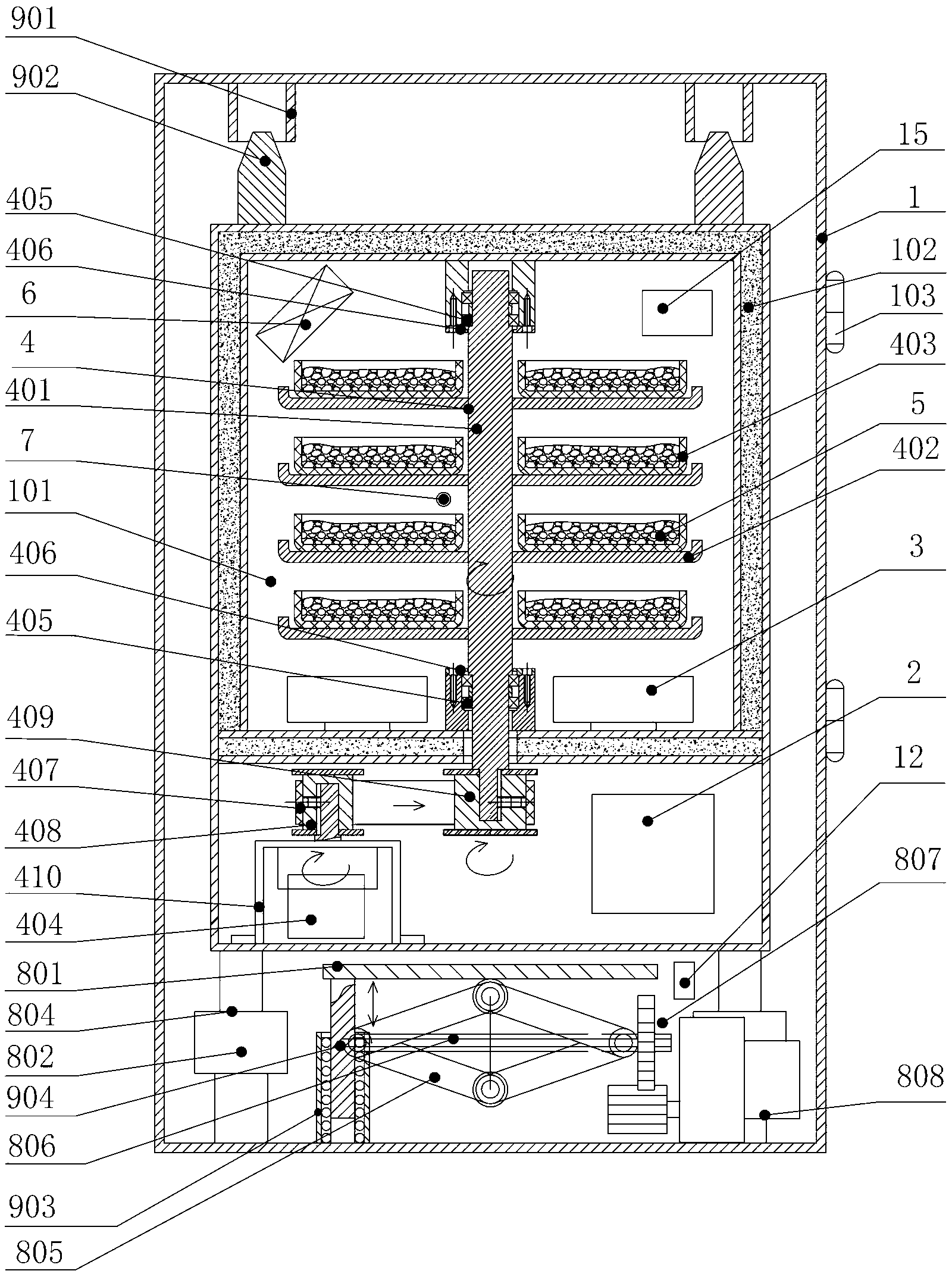

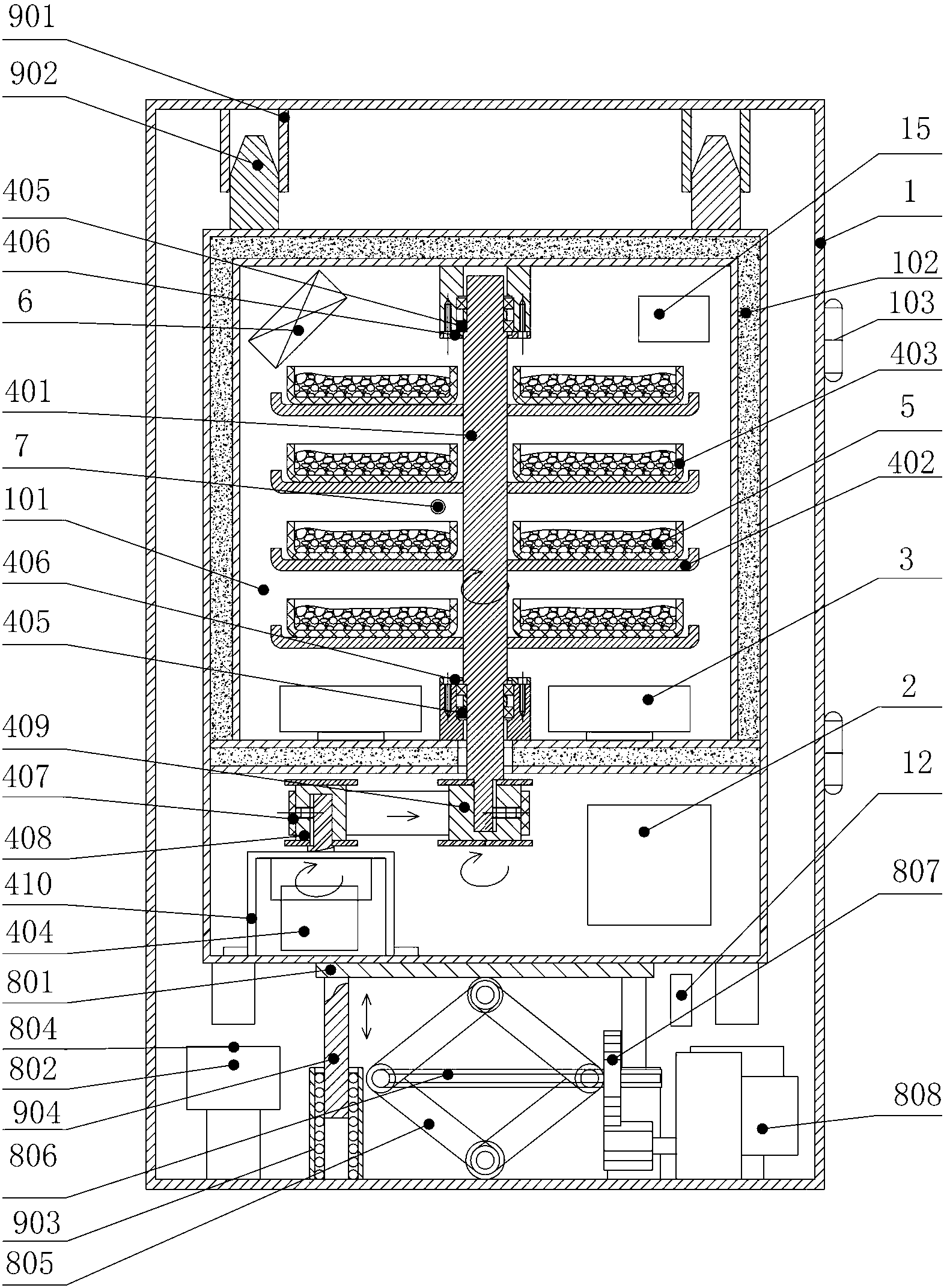

[0023] Such as figure 1 As shown, the horizontal rotating coal sample rapid dehumidification device with moisture dynamic detection of the present invention includes a cabinet 1, a horizontal rotating mechanism 4, a controller 2, more than one heater 3, and a moisture dynamic detection component. The chamber is the dehumidification chamber 101, and the heater 3 is installed in the dehumidification chamber 101 and connected to the controller 2 to increase the temperature in the dehumidification chamber 101 to dehumidify the coal sample 5. The controller 2 uses To control the work of the heater 3. The horizontal rotation mechanism 4 includes a drive transmission assembly and a sample disk rotating shaft 401 located in the dehumidifying chamber 101. The sample disk rotating shaft 401 is arranged along the vertical direction. The sampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com