Production process of permeation dehydrated-microwave dried pleurotus eryngii and product

A production process and technology for king oyster mushrooms, which are applied in the direction of preservation of fruits/vegetables by dehydration, food processing, etc., can solve the problems of high production energy consumption, loss of nutrients, poor quality, etc., and achieve the goal of reducing energy consumption and improving production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Cleaning, peeling, and slicing: choose Pleurotus eryngii mushrooms with thick flesh, crisp and tender texture, and milky white as raw materials, and use SA-300D semi-automatic slicer (Guangzhou Minhong Food Machinery Co., Ltd.) to slice, and the slice thickness is 6mm;

[0028] 2. Color protection: quickly place the Pleurotus eryngii slices in the color protection solution, which is a mixture of 0.2% citric acid, 0.3% Vc and 1% sodium chloride, for 40 minutes;

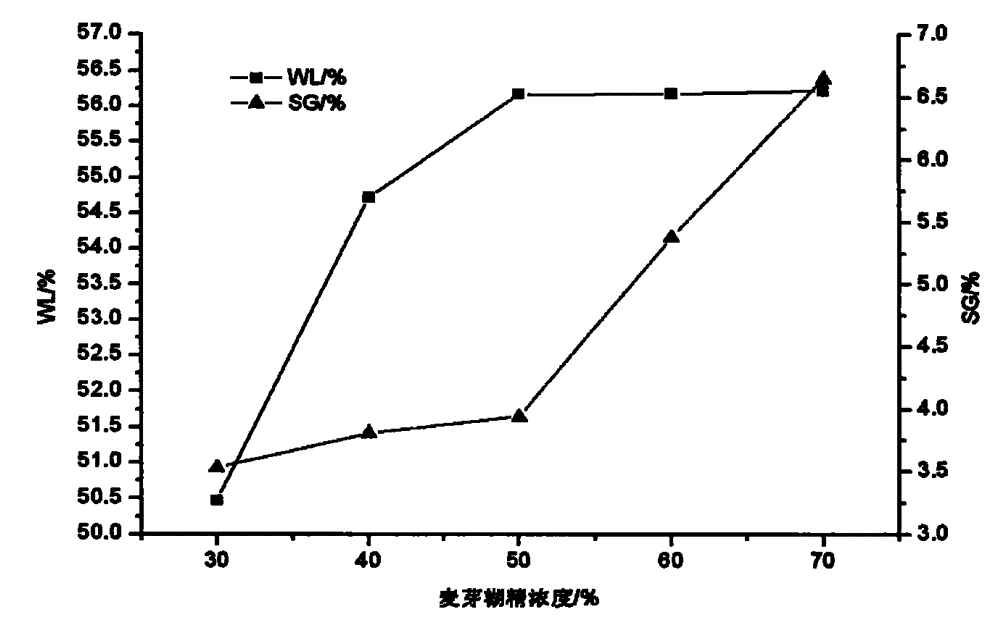

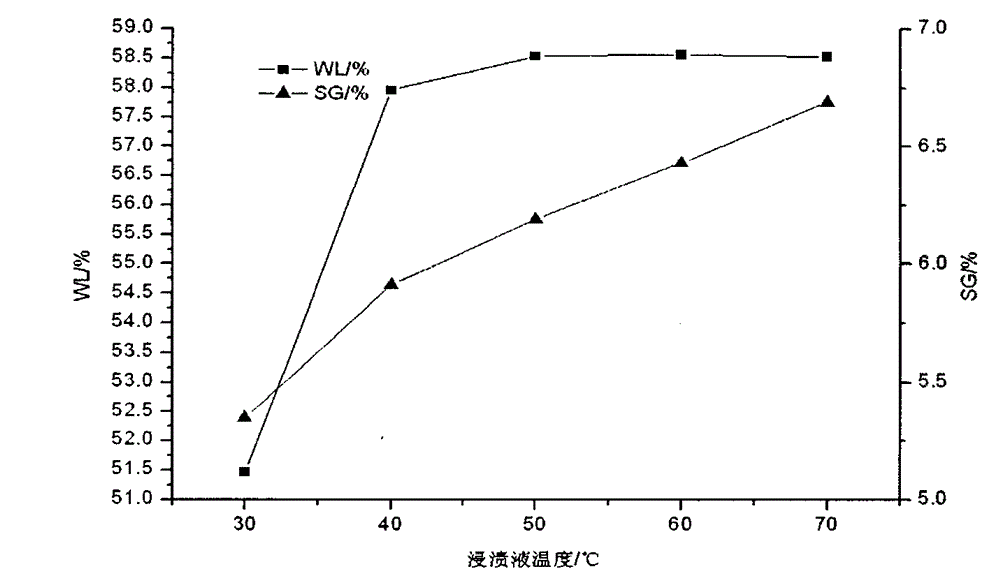

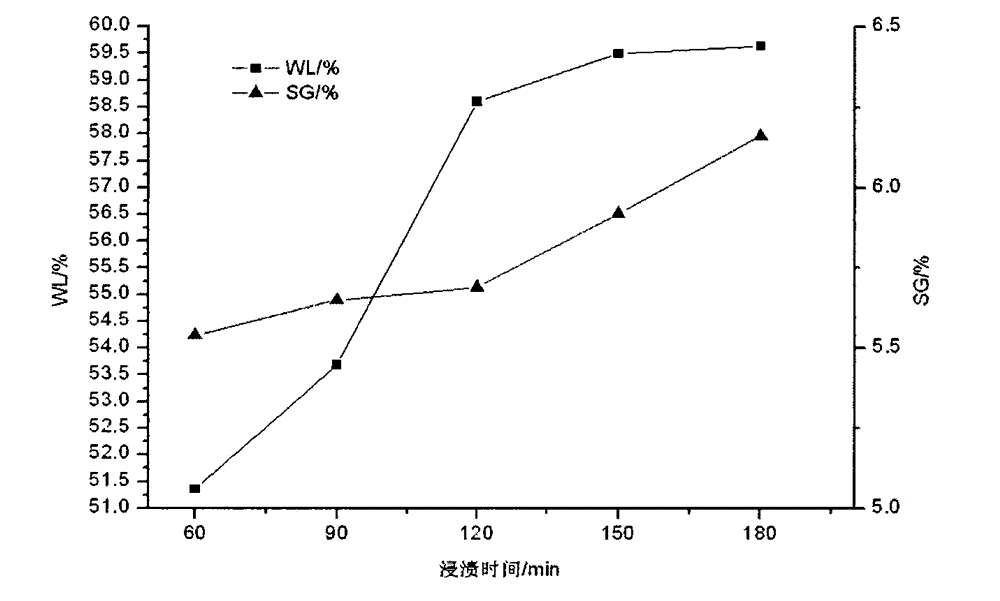

[0029] 3. Osmotic dehydration: put Pleurotus eryngii slices in 40% maltodextrin solution, the temperature of the solution is controlled at 40°C, and soak for 120 minutes for osmotic dehydration;

[0030] 4. Refrigerated treatment: place the Pleurotus eryngii slices in a 5°C refrigerator for refrigerated treatment;

[0031] 5. Microwave drying: place the permeated and dehydrated Pleurotus eryngii slices on the conveyor belt of 6CW-10E tunnel microwave drying equipment (Nanjing Greatpower Microwave Technology D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com