Process for steaming and baking fresh bamboo through biomass gasification

A technology for biomass and fresh bamboo shoots, applied in the field of steaming and roasting technology, can solve the problems of high cost, complex equipment, extensive methods, etc., and achieve the effect of improving the quality of the finished product and reducing the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

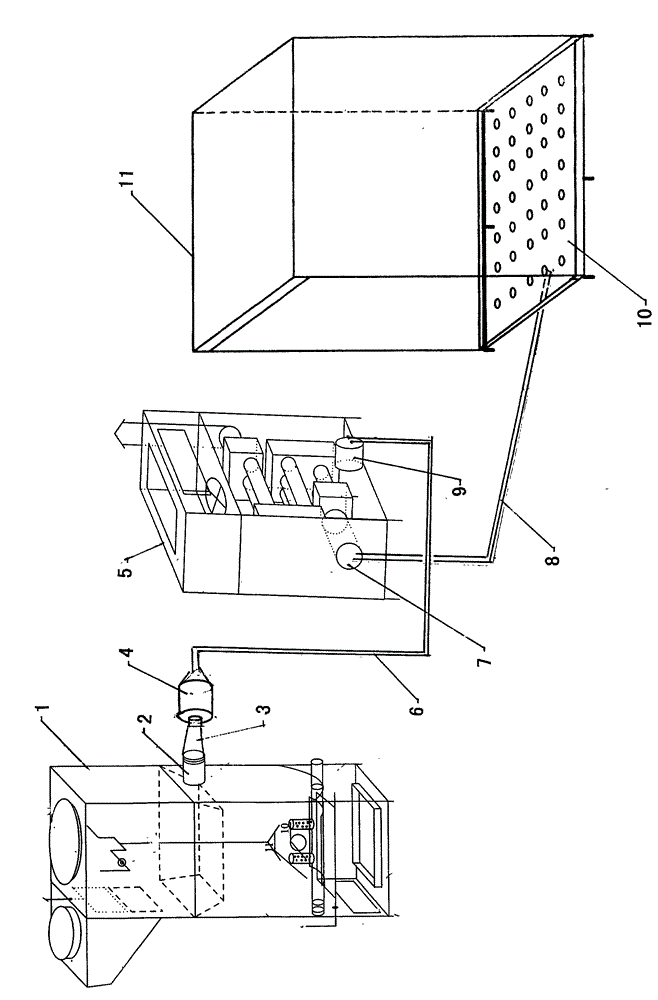

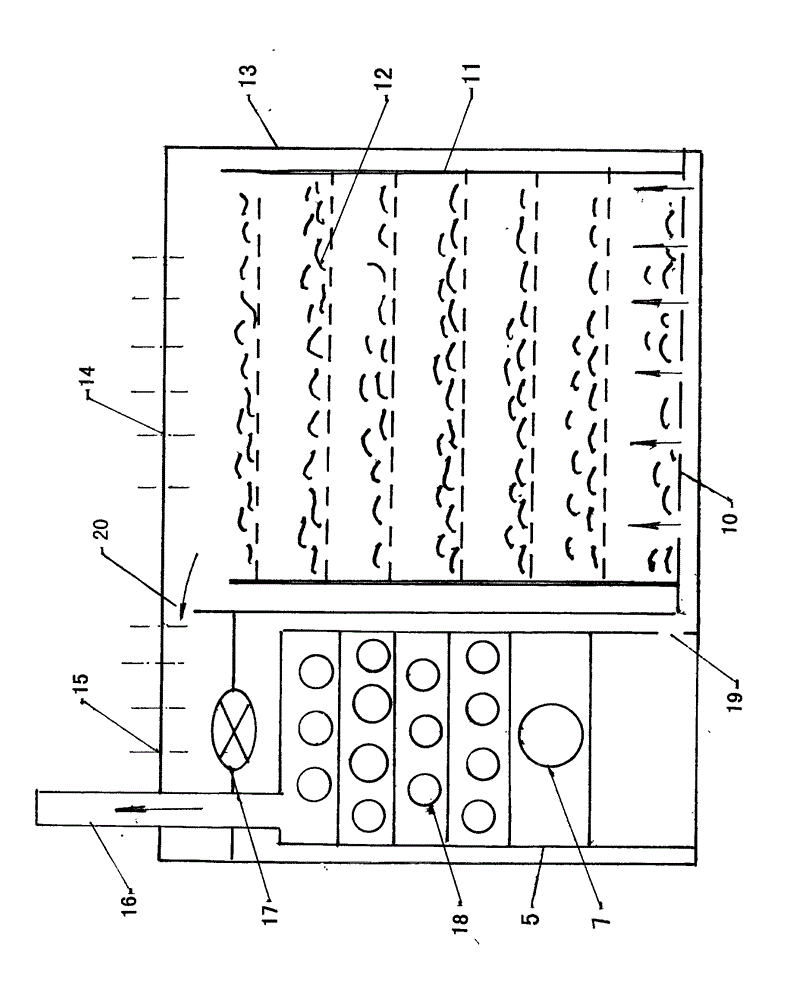

[0011] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0012] (Such as figure 1 Shown) The equipment used for a kind of biomass gasification, steaming and roasting fresh bamboo shoots process of the present invention includes a biomass gasification furnace 1, a crude gas pipe 2, a crude gas output pipe 3, a burner 4, and a heat exchange box 5 , hot gas delivery pipe 6, hot air outlet pipe 7, hot air delivery pipe 8, hot air input pipe 9, rack 10, baking oven 11 and steaming room 13, wherein said biomass gasification furnace is a prior art , has been introduced in detail in the same applicant's "biomass gasification furnace carbonization material production process", and the heat exchange box 5 is also described in detail in the same applicant's "biomass gasification heat exchange box". (Depend on figure 2 Shown) heat exchange case 5 is made of waste discharge pipe 16, hot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com