Special wheel cake loading and unloading robot for automatic production line

An automatic production line and robot technology, applied to cranes, etc., can solve the problems of unobtainable cost, unreachable design lifting weight or slewing speed, etc., and achieve fast slewing speed, stable clamping effect, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings.

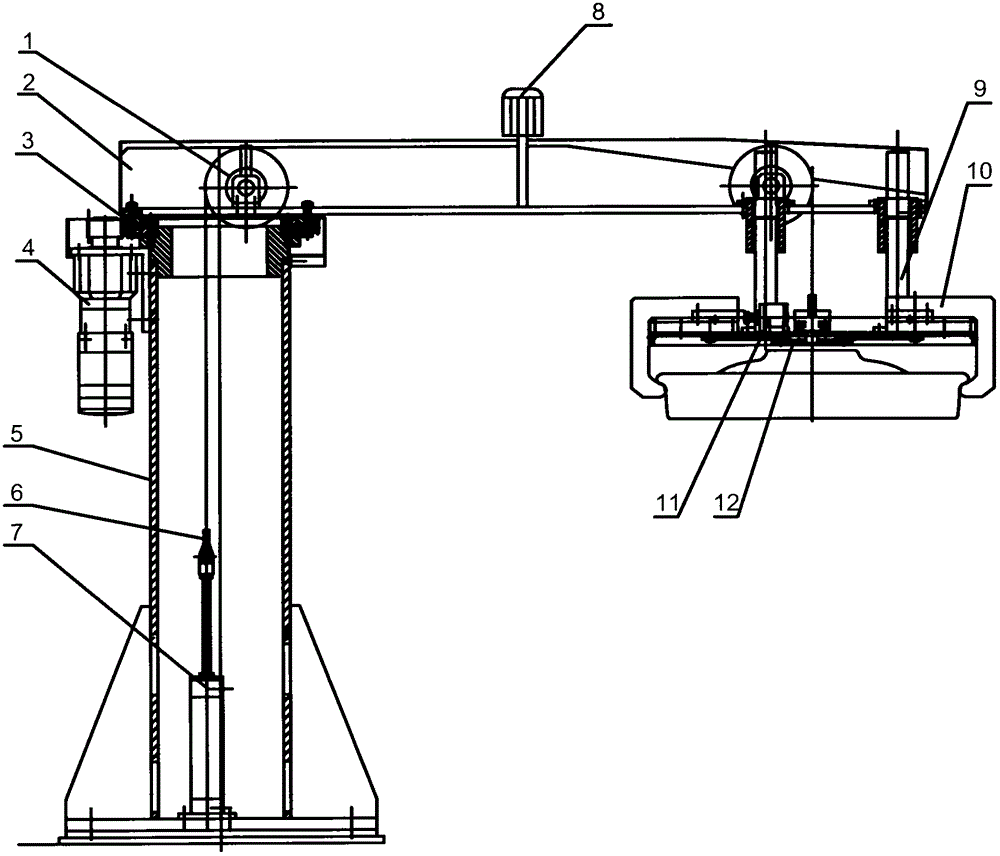

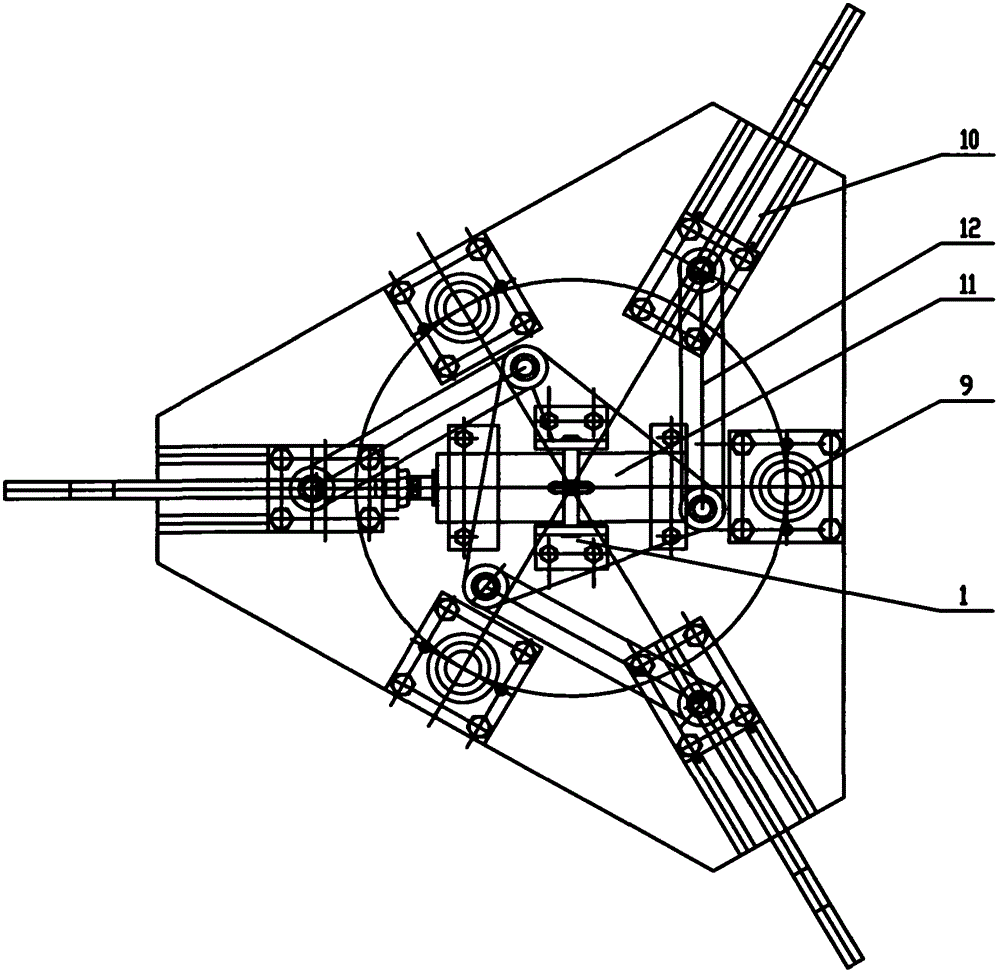

[0011] see figure 1 , 2 The equipment structure of the present invention consists of a pulley block 1, a rotary arm 2, a gear pair 3, a rotary servo motor 4, a body 5, a steel wire rope 6, a claw lifting cylinder 7, a rotary flashing light 8, a guide column 9, a claw 10, and a claw opening The robot system is composed of an oil cylinder 11 and a connecting rod group 12. The robot system uses the body 5 as a basic support, and all parts are connected to it, and the tilting moment is transmitted to the civil foundation through it; the slewing arm 2 is connected to the body through the gear pair 3 5, and connected with the gripper 10 through the guide column 9; the rotary servo motor 4 is fixed on the side of the body 5 by screws, and connected with the rotary arm 2 through the gear pair 3, driving the rotary arm 2 to rotate, and the gear pair 3 is fixed by scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com