Waste tire regeneration processing technology

A technology of waste tires and processing technology, which is applied in the field of recycled rubber production, can solve the problems of low economic and social benefits, unfavorable resource recycling, and low rubber technical indicators, and achieve the effects of high viscosity, uniform texture, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

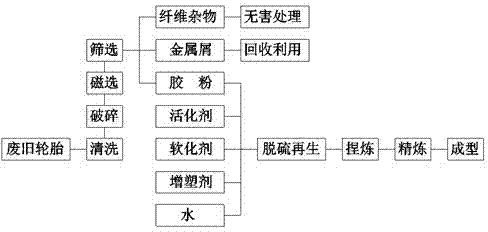

Method used

Image

Examples

Embodiment 1

[0014] Wash, crush, magnetically separate and screen old tires to obtain 100kg of rubber powder with a particle size of 40 mesh, add 0.1kg of 420-type activator, 15kg of softener pine tar, 4kg of plasticizer rosin, and 9kg of water. Put it into the desulfurization tank and close it. While stirring at a constant speed, raise the temperature in the tank to 180°C, and the pressure in the tank to 3.8MPa. After maintaining the pressure for 3 hours, discharge the material, and then obtain reclaimed rubber blocks after kneading, refining and molding processes. After testing, the obtained reclaimed rubber has a moisture content of 1.15%, ash content of 9.2%, acetone extract content of 18.6%, tensile strength of 9.8MPa, elongation at break of 405%, and Mooney viscosity of ML100°C (1+ 4) It is 69, and all performance indicators are in line with the provisions of the national standard GB / T13460-2008 for high-grade products.

Embodiment 2

[0016] After cleaning, crushing, magnetic separation and screening of old tires, 100kg of rubber powder with a particle size of 30 meshes was obtained, 1.2kg of 420-type activator, 15kg of softener pine tar, 2.3kg of plasticizer rosin, and 9kg of water were added, and the above materials were simultaneously Put it into a desulfurization tank and close it. While stirring at a constant speed, raise the temperature inside the tank to 199°C, and the pressure inside the tank to 2.8MPa. Keep the pressure for 2 hours before unloading, and then kneading, refining and molding processes to obtain reclaimed rubber. After testing, the moisture content of the obtained reclaimed rubber is 1.1%, the ash content is 9.8%, the acetone extract is 19.8%, the tensile strength is 10.2MPa, the elongation at break is 400%, and the Mooney viscosity is ML100°C (1 +4) is 68, and all performance indicators are in line with the provisions of the national standard GB / T13460-2008 for high-grade products.

Embodiment 3

[0018] After cleaning, crushing, magnetic separation and screening of old tires, 100kg of rubber powder with a particle size of 35 meshes was obtained, 0.1kg of 420-type activator, 20kg of softener pine tar, 2.3kg of plasticizer rosin, and 9kg of water were added. Put it into the desulfurization tank and close it. While stirring at a constant speed, raise the temperature inside the tank to 190°C, and the pressure inside the tank to 3.2MPa. After keeping the pressure for 2.5 hours, discharge the material, and then obtain reclaimed rubber after kneading, refining and molding processes. After testing, the moisture content of the obtained reclaimed rubber is 1.2%, the ash content is 8.6%, the acetone extract is 19%, the tensile strength is 9.9MPa, the elongation at break is 392%, and the Mooney viscosity is ML100°C (1 +4) is 70, and all performance indicators are in line with the provisions of the national standard GB / T13460-2008 for high-grade products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com