Method for preparing paint remover suitable for epoxy group printed circuit board

A technology of printed circuit board and paint remover, applied in the direction of chemical paint/ink remover, coating, etc., can solve the problems of difficult application in the electronic field, loss of protection, application limitation, etc., to shorten the time required for paint removal , Increase the removal time, the effect of flexible paint removal method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

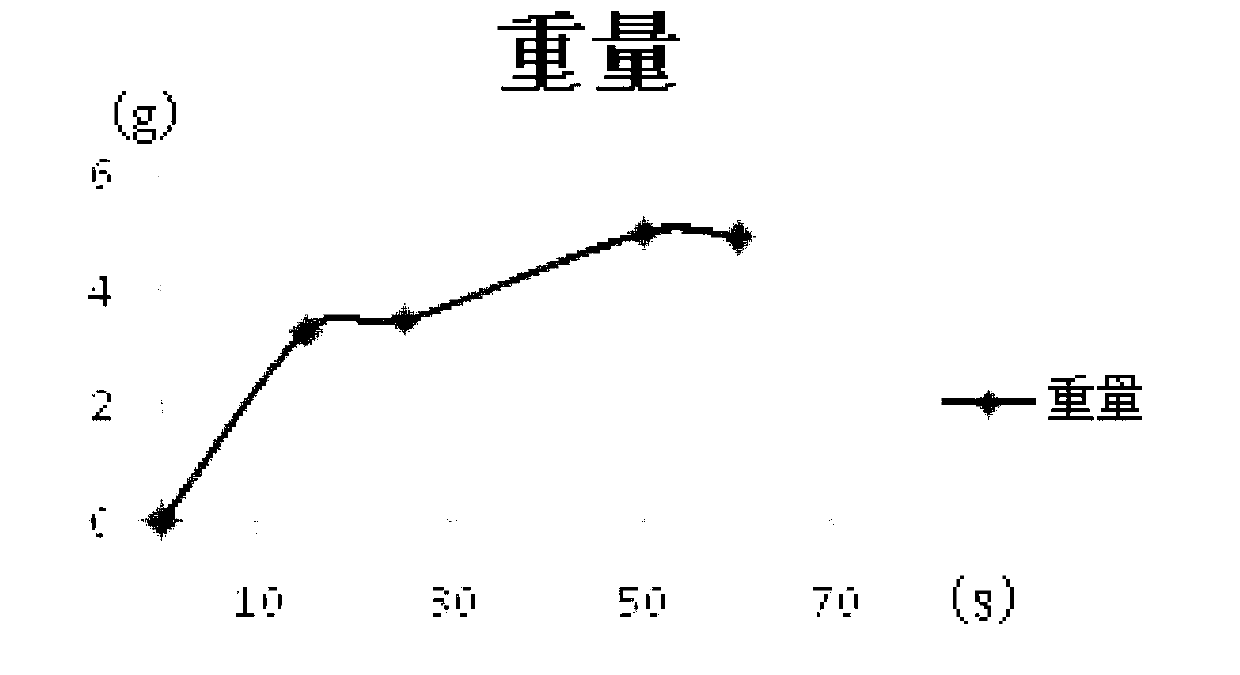

[0034] The preparation method of paint remover suitable for epoxy-based printed circuit boards includes the following steps:

[0035] 1) Use the extraction method to mix the TQJ101 enameled wire paint remover produced by Wantong Electronics, weigh 10g, put it into the separatory funnel, add 2 to 3 times the volume of deionized water, and remove from the lower part of the separatory funnel. After the extraction of the paint remover and deionized water solution, pour out the residual deionized water, repeat the extraction several times, and measure the pH value of the residual deionized water with a pH test paper each time. When the pH value reaches 4, remove the paint Adjust the pH of the agent in place, this operation can reduce the acidity in the original paint remover;

[0036] 2) Add 1.6g~1.8g of methamphetamine to the adjusted paint remover, which is a corrosion inhibitor for solder materials, which can reduce the corrosion of metal materials by solvents;

[0037] 3) After stirr...

Embodiment 2

[0040] The preparation method of paint remover suitable for epoxy-based printed circuit boards includes the following steps:

[0041] 1) Use the extraction method to mix the TQJ101 enameled wire paint remover produced by Wantong Electronics, weigh 10g, put it into the separatory funnel, add 2 to 3 times the volume of deionized water, and remove from the lower part of the separatory funnel. After the extraction of the paint remover and deionized water solution, pour out the residual deionized water, repeat the extraction several times, and measure the pH value of the residual deionized water with a pH test paper each time. When the pH value reaches 4.2, remove the paint Adjust the pH of the agent in place, this operation can reduce the acidity in the original paint remover;

[0042] 2) Add 1.8g to 2g of methamphetamine to the adjusted paint remover, which is a corrosion inhibitor for solder materials, which can reduce the corrosion of metal materials by solvents;

[0043] 3) After st...

Embodiment 3

[0046] The preparation method of paint remover suitable for epoxy-based printed circuit boards includes the following steps:

[0047] 1) Use the extraction method to mix the TQJ101 enameled wire paint remover produced by Wantong Electronics, weigh 10g, put it into the separatory funnel, add 2 to 3 times the volume of deionized water, and remove from the lower part of the separatory funnel. After the extraction of the paint remover and deionized water solution, pour out the residual deionized water, repeat the extraction several times, and measure the pH value of the residual deionized water with a pH test paper each time. When the pH value reaches 4, remove the paint Adjust the pH of the agent in place, this operation can reduce the acidity in the original paint remover;

[0048] 2) Add 1g~1.2g of methamphetamine to the adjusted paint remover, which is a corrosion inhibitor for solder materials, which can reduce the corrosion of metal materials by solvents;

[0049] 3) After stirrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com