Balancing method for bacterial type looped blade roots and blades

A blade and coil forming technology, which is applied in the direction of blade support components, engine components, machines/engines, etc., can solve the problems of inability to assemble and poor balance of mushroom-shaped blade roots and blades, and achieve reasonable design, simple and clear steps, and feasibility high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

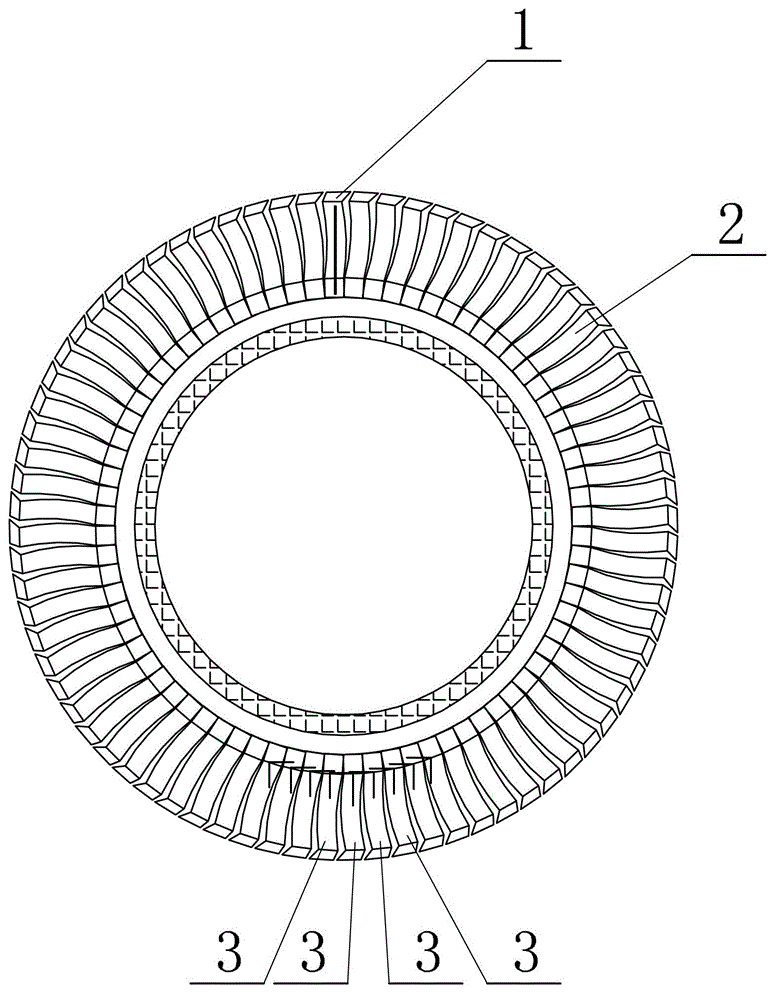

[0018] Specific implementation mode one: combine figure 1 Describe this embodiment, the specific steps of the method described in this embodiment are as follows:

[0019] Step 1. Searching and weighing: the coiled fungus-shaped leaf root leaves include a titanium alloy blade 1 and multiple ordinary alloy steel blades 2. According to the shape of the blades, find out the titanium alloy blade 1 and ordinary alloy steel blades among the coiled leaves. alloy steel blade 2 and weigh the weight M of a single common alloy steel blade 2 t And the weight M of a single titanium alloy blade 1 2 , and calculate the weight difference between the two: M 1 -M 2 =ΔM;

[0020] Step 2. Calculating the weight loss: In order to meet the balance of the fungus-shaped leaf root and blade roulette, a region of the common alloy steel blade 2 is processed, and a specific part of the common alloy steel blade 2 is cut off to achieve a ring-shaped fungus Requirements for the balance of the blade root...

specific Embodiment approach 2

[0028] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the common alloy steel blade 2 in this embodiment is a 17-4PH alloy steel blade, a 12CrMo alloy steel blade or a 1Cr12Mo alloy steel blade. 17-4PH alloy steel, 12CrMo alloy and 1Cr12Mo alloy steel are all available alloy steels, and blades made of these alloy steels are suitable for the present invention. Other method steps are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com