Elastic adjustable sparking plug sealing structure

A sealing structure and adjustable technology, which is applied in the direction of spark plugs, engine sealing devices, spark ignition controllers, etc., can solve the problems of inability to make up for the machining error of the spark plug installation hole of the spacer and the cylinder cover, insufficient sealing of the cylinder cover, etc. Inability to achieve elastic adjustable sealing and other problems, to achieve the effects of saving assembly time, good sealing, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

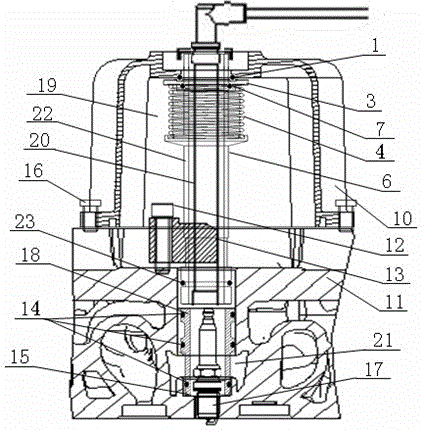

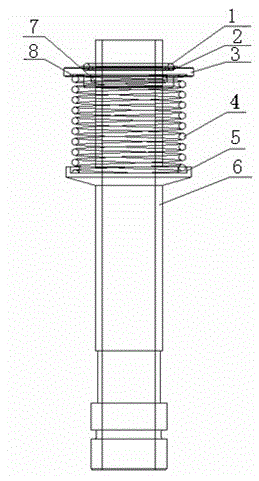

[0024] see figure 1 , Figure 3-Figure 5 , the cylinder head oil and gas chamber is composed of a cylinder cover 10, a cylinder cover chamber 19 and a cylinder head 11, a spark plug 17 is arranged in the cylinder head 11, and a high voltage line 20 is arranged on the outside of the spark plug 17, an elastic adjustable spark plug sealing structure, comprising Spacer 6, the spacer 6 separates the high voltage line 20 from the cylinder cover chamber 19 and the spark plug 17 from the water jacket 21, the spacer 6 extends out of the cylinder cover 10, and the lower end surface of the spacer 6 contacts the cylinder head 11 A gasket is provided between the surfaces; the spacer 6 inside the cylinder cover 10 is provided with a pressure plate 3, the central hole wall of the pressure plate 3 is socketed with the outer peripheral surface of the spacer 6, and the upper surface of the pressure plate 3 The end surface is in contact with the top of the cylinder cover 10, and a spring 4 is s...

Embodiment 2

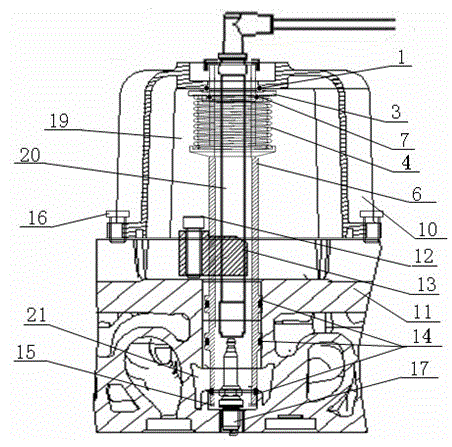

[0026] see Figure 2-Figure 5, The cylinder head oil and gas chamber is composed of the cylinder cover 10, the cylinder cover chamber 19 and the cylinder head 11. The cylinder head 11 is provided with a spark plug 17, and the outside of the spark plug 17 is provided with a high voltage line 20. An elastic adjustable spark plug sealing structure, including a spacer 6, the spacer 6 separates the high voltage line 20 from the cylinder cover chamber 19 and the spark plug 17 from the water jacket 21, and the spacer 6 extends out of the cylinder cover 10, A gasket is provided between the lower end surface of the spacer 6 and the contact surface of the cylinder head 11. A pressure plate 3 is arranged on the spacer 6 inside the cylinder cover 10, and the center hole wall of the pressure plate 3 is in contact with the outer circumferential surface of the spacer 6. The upper end surface of the pressure plate 3 is in contact with the top of the cylinder cover 10, and the spring 4 is set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com